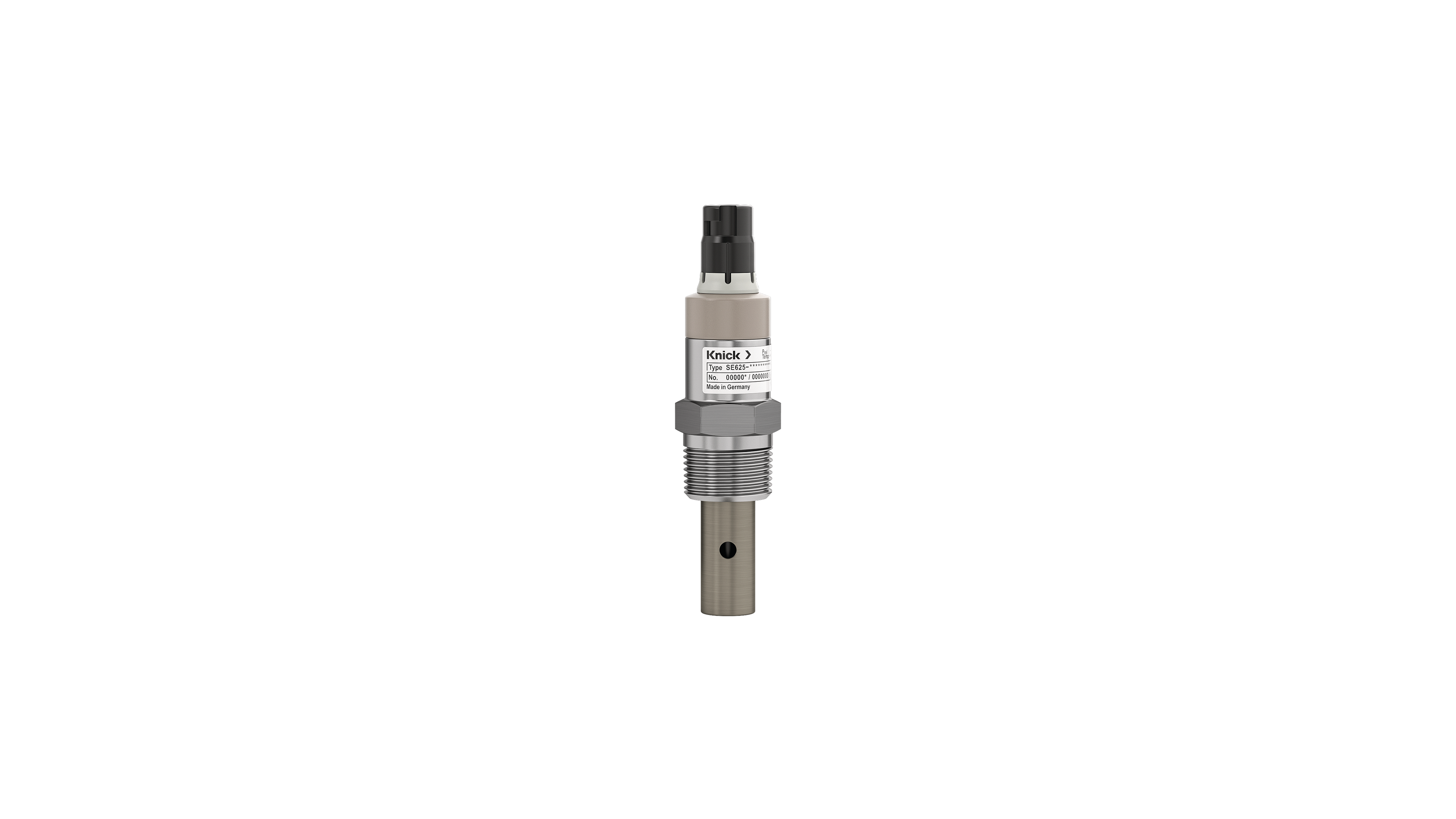

SE655 Toroidal Conductivity Sensor | Fixed cable | Ex | PEEK | High chemical resistance

Description

Universal and precise sensor with high chemical resistance over a very large measuring range, for heavily polluted media.

- Measurement in hazardous locations

- Sturdy design

- Extremely large measuring range due to inductive measuring principle

- Insensitive to contamination

- No process-wetted electrodes

- High chemical resistance (PEEK)

- Steam-sterilizable

- CIP-capable

Corrosion-resistant toroidal sensor for measuring pure water up to maximum conductivities. Smooth, easy-to-clean design. High accuracy due to electrodeless measurement. Low risk of contamination because of large sensor opening. Also for hazardous locations.

Applications

Concentration measurement of acid and alkaline solutions, heavily polluted media, coating-forming and oil-containing media, salt spring, heavily polluted wastewaters, cooling water blowdown, concentrate monitoring, regeneration of ion exchangers

We look forward to hearing from you!

Contact Us

| Measurement Parameter: | Conductivity (inductive) |

|---|---|

| Measurement error: | ± (0.005 mS/cm + 0.5 % meas. value) | (- 20 ... 100 °C), ± (0.010 mS/cm + 0.5 % meas. value) | (> 100 °C) |

| Mounting: | G ¾" |

| Measuring Range: | 0 … 2,000 mS/cm, 0.002 … 2,000 mS/cm |

| Explosion protection: | Yes |

| Process Connection: | G3/4“ (Union nut A/F36 and FKM (Viton) seal in package contents) |

| Temperature: | -20 … 125 °C |

| Temperature Detector: | Pt100 (Class A) |

| Measuring principle: | Inductive |

| Pressure: | 0 … 20 bar |

| Material: | PEEK |

| Cable: | Fixed cable, 5 m |

| Protection: | IP 68 (when mounted) |

| Cell factor: | Approx. 2/cm (≥ 30 mm distance to wall) |

| Signal Transmission: | analog |