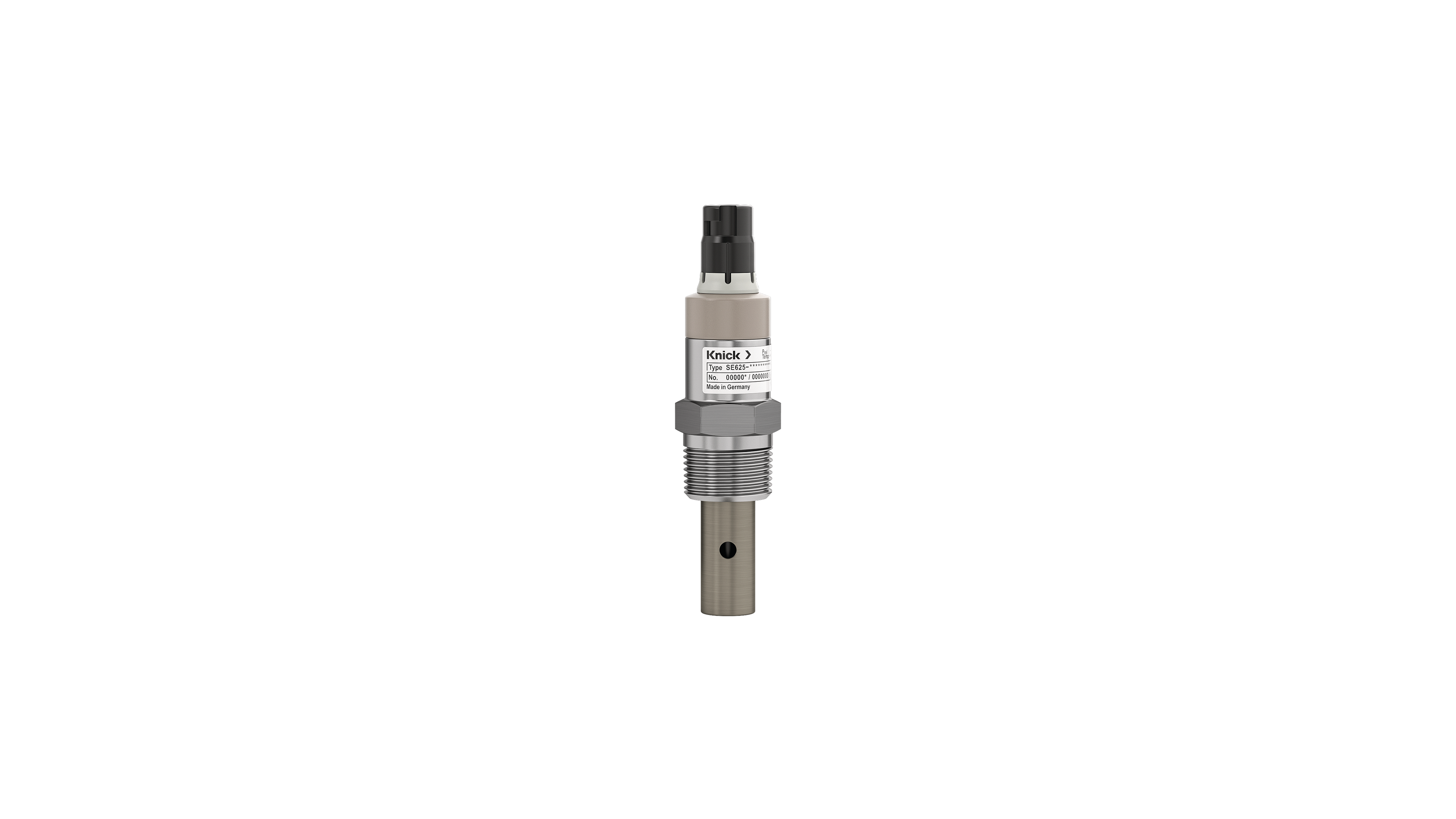

SE680 Digital Toroidal Conductivity Sensor | SMS 2" | Ex | FDA-approved PEEK | Measuring range 0 … 2000 mS/cm

Description

High-precision sensor made of FDA-approved PEEK with an extremely large measuring range. Steam-sterilizable.

- Compact design

- Competitively priced

- Large measuring range

- Quick-reacting temperature detector

- Digital data transfer

- Completely closed surface

- Virgin PEEK, FDA type

- Varivent with EHEDG

The joint- and gap-free, sealless design and stain-resistant surface made of Virgin PEEK make the SE680 a heavy-duty sensor. The inductive technology is not influenced by polarization and does not have any sensor surfaces subject to corrosion.

Applications

Fresh water technology, dairy products, breweries, soft drink manufacturing, electroplating, air-conditioning, CIP monitoring in the beverage industry, pharmaceutical applications, cooling tower monitoring, on-site wastewater treatment plants, monitoring concentrations of salt solutions, alkalis and acids, washers, and rinsing processes

We look forward to hearing from you!

Contact Us

| Error: | ± 1 % meas. val. + 0.002 mS/cm, ± 0.02 %/K |

|---|---|

| Measurement Parameter: | Conductivity (inductive) |

| Measuring Range: | 0 … 2,000 mS/cm |

| Explosion protection: | Ex-Zone 0 (for SE680), Yes |

| Process Connection: | SMS 2" |

| Temperature Detector: | Pt1000 |

| Measuring principle: | Inductive |

| Relative process pressure: | –0.1 ... 10 bar (see Pressure/Temperature Diagram) |

| Wetted materials: | Virgin PEEK, FDA-type |

| Response time: | t90 < 30s |

| Cell factor: | c≈ 5.0/cm |

| Signal Transmission: | digital |

| Non-wetted materials: | PP-ESD |

| Electrical connection: | Plug, M12 – 4-pin; max. cable length 100 m |

| Sterilization: | ≤ 5 bar / ≤ 150 °C / ≤ 60 min |