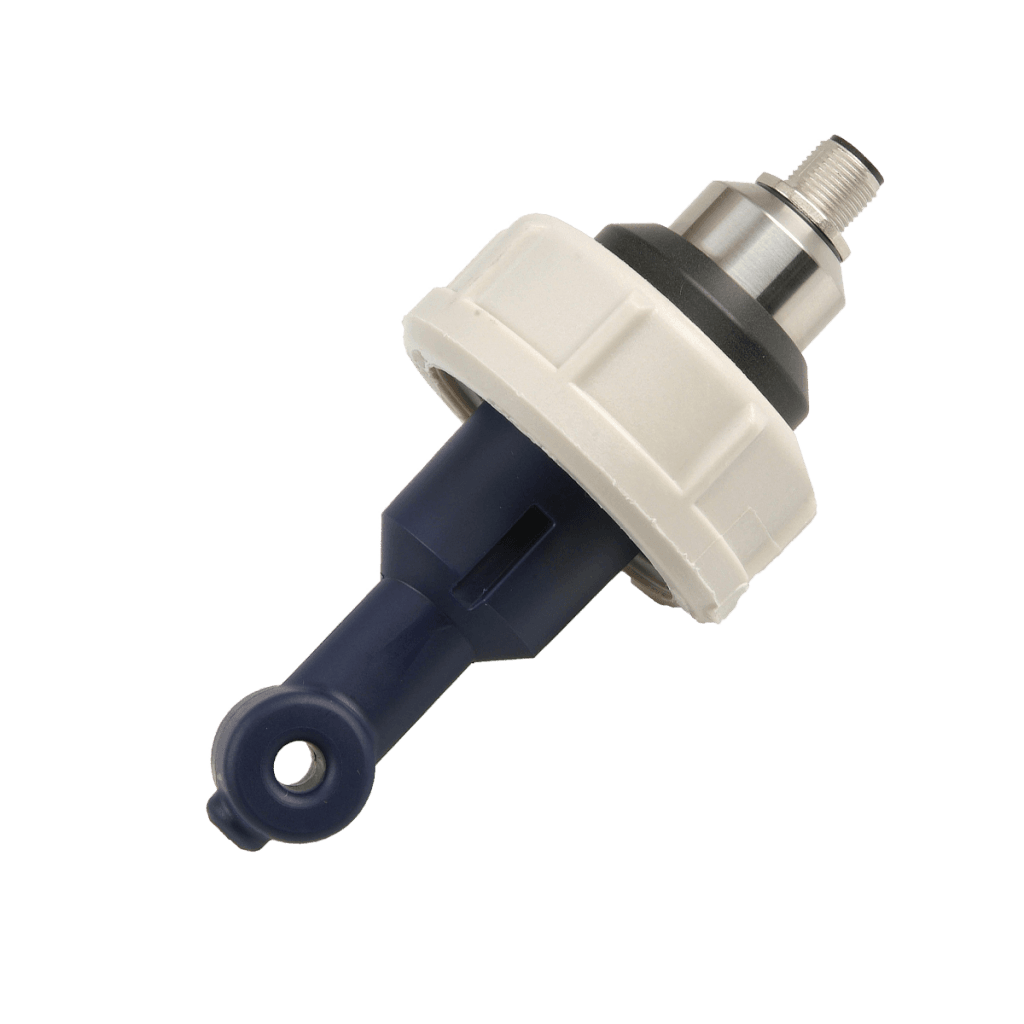

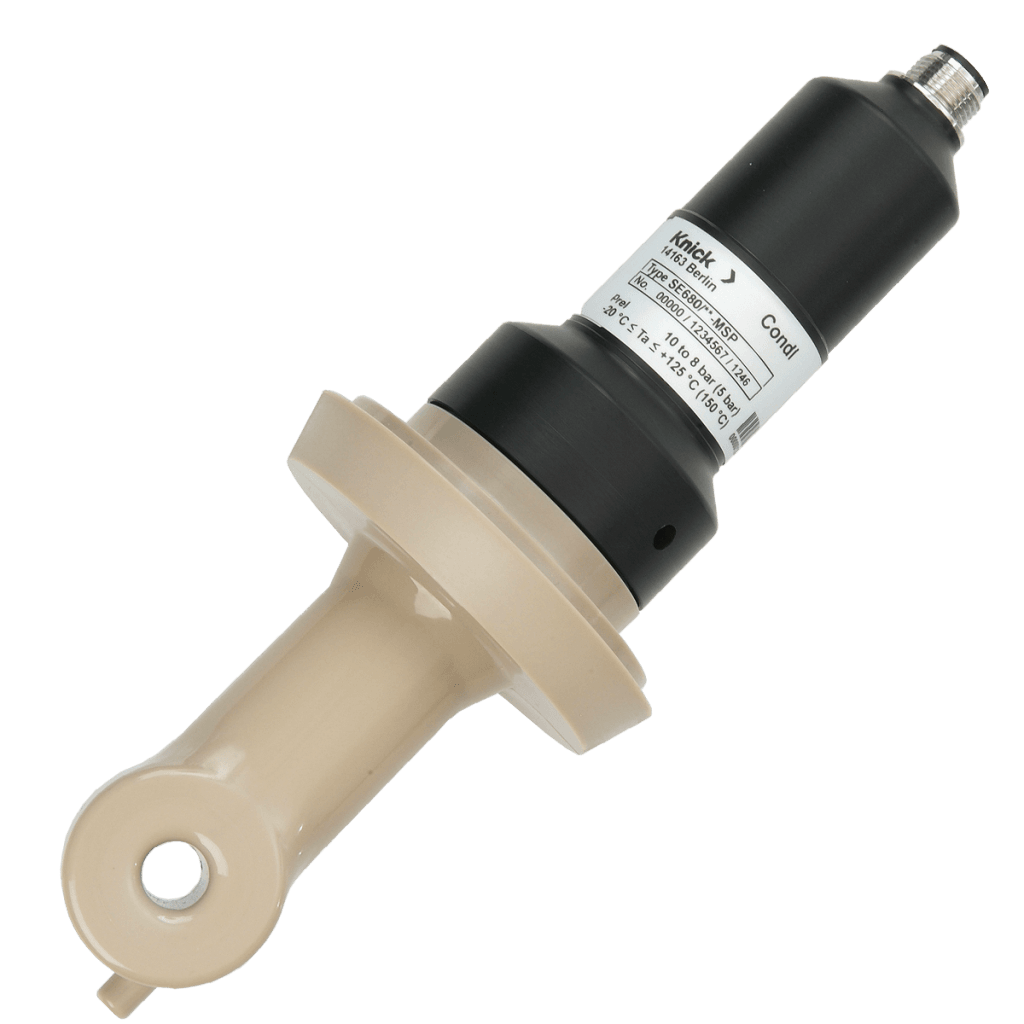

SE670 Toroidal Conductivity Sensor | Coupling nut G 1 1/2“ | PP | Insensitive to contamination and corrosion

Description

Competitively priced digital sensor for measuring low to very high conductivity values, insensitive to contamination and corrosion.

Digital toroidal conductivity sensor for measuring low to high conductivity.

- Process-wetted material: PP

- Compact size

- Resistant to pollution and deposit formation

- Range of six decades

- Inductive measuring principle, full galvanic isolation of sensor coils from the process medium

- Digital data transmission

- Cable length up to 100 m

The SE670 is a universal conductivity sensor with a compact size. The combination of a large sensor opening and dirt-repellent material prevents blockages and deposits in media with

a high pollution degree. The inductive measuring principle enables the full galvanic isolation of the measurement from the medium.

An all-rounder, the sensor with a six-decade range is suitable for a multitude of applications.

Applications

Fresh water and wastewater technology; electroplating; photographic processes; air conditioning systems; cooling tower monitoring; company water treatment plants; salt, brine and general concentration monitoring; tanneries; mordant preparation; washing facilities; vehicle technology; flushing processes

- Digital data transfer

- Cable length up to 100 m

- Competitively priced

- Compact design

- No process-wetted electrodes

- Large measuring range

- Quick-reacting temperature detector

- Insensitive to deposits and contaminations

We look forward to hearing from you!

Contact Us

| Measurement Parameter: | Conductivity (inductive) |

|---|---|

| Connector: | M12 |

| Measuring Range: | 0.02 … 2,000 mS/cm |

| Process Connection: | Coupling nut G1½″ |

| Temperature: | 0 … 60 °C (momentarily 100 °C) |

| Temperature Detector: | Pt1000 |

| Measuring principle: | Inductive |

| Pressure: | Max. 6 bar (60 °C), Max. 10 bar (20 °C) |

| Material: | PP (polypropylene) |

| Cell factor: | Approx. 6.4/cm |

| Signal Transmission: | digital |

| Temperature response time: | Quick, using extrapolation with neuronal process |