Hydrogen Energy: Powering the Future with Knick Measurement Technology

Hydrogen is a key player in today’s world of energy production and storage. Knick has proven to be a trusted partner to the industry by way of providing electrical measurement solutions that meet the challenging application requirements seen. Our robust transducers for monitoring critical system variables like voltage, current, and temperature, help to ensure that measurements are performed both accurately and safely within the high-voltage environments encountered. Robust electrical isolation engineered into circuit design is the important common denominator.

Industry Advances Require Precision and Accuracy, While Ensuring Electrical Safety

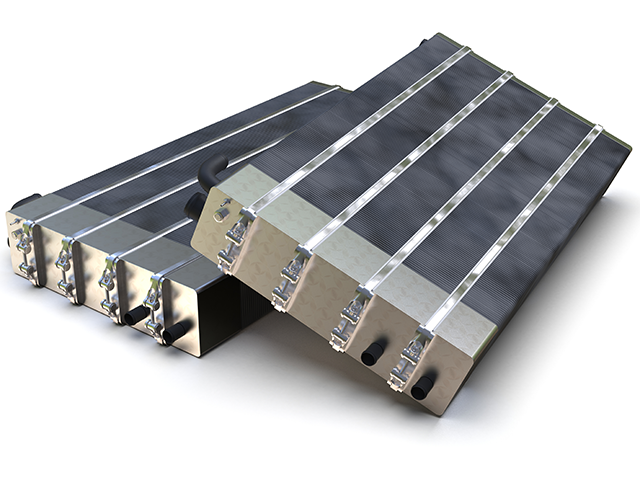

The capability of electrolyzers that produce hydrogen from a combination of electricity and chemistry is constantly improving. Similarly, the capacity of fuel cell systems designed for the efficient storage and conversion of hydrogen back into electricity is ever growing.

These advances are not without their share of challenges. Both electrolyzers and fuel cell systems contain low voltage building blocks which are arranged into larger units called stacks. These stacks are often combined to create even more powerful systems, which are defined as strings. The larger the string, the greater the overall voltage potential. This means that even when looking to monitor and track the performance of low-voltage cell building blocks, protection from the higher overall system voltage must be ensured. This is not an easy task. It requires a carefully thought-out approach along with hardware that can meet the demands.

Knick transducers are designed to meet these challenges, by employing accuracy and precision to ensure resolution of both low and high voltage measurements, while offering the necessary electrical protection by way of strong isolation principles. This same performance is brought to temperature and current monitoring, which also requires high-voltage isolation. Knick has seen success in hydrogen applications exceeding 2000 VDC, and remains ready to perform at levels above this, as the industry continues to reach new heights.

Electrolyzer Control

Fuel Cell Monitoring

Rectifier Verification

On-Site Data Collection

Why Knick?

Knick’s commitment to manufacturing and engineering excellence for over 80 years brings the experience necessary to perform in challenging applications encountered by Hydrogen Energy professionals. With continuous electrical isolation up to 4.8 kV, peace of mind is brought to critical high-voltage applications. Performance is further verified by way of stringent standards and approvals met, presented clearly and meticulously in each device datasheet.

Technology Highlight – Ensuring Functional Safety of Hydrogen Applications Through SIL Approved Hardware

Due to the potentially hazardous conditions seen with hydrogen production and storage, high levels of safety are engineered into systems and processes. This is especially important within high-voltage environments, where standards for functional safety, as defined by SIL approval, are followed to ensure that safety circuits are designed in a high-quality, fail-safe manner.

Knick’s SIL-rated transducers are designed for usage in hydrogen electrical safety circuits, ensuring measurements are made with the utmost device reliability, through functional safety compliance. Knick transducers are the first of their kind, offering SIL 2 level protection in critical applications, and up to SIL 3 when used in a redundant configuration.

Additional SIL-rated options exist with Knick products designed for signal duplication, helpful when connected to devices like door sensors or flow switches dedicated within safety control circuits. This allows the possibility for sensor information to also be captured for data collection or condition monitoring purposes, allowing more functionality for an existing sensor network.

Related Applications

Do you have more questions? We are here for you.

Contact us!