The sun factor: Monitoring photovoltaic power stations

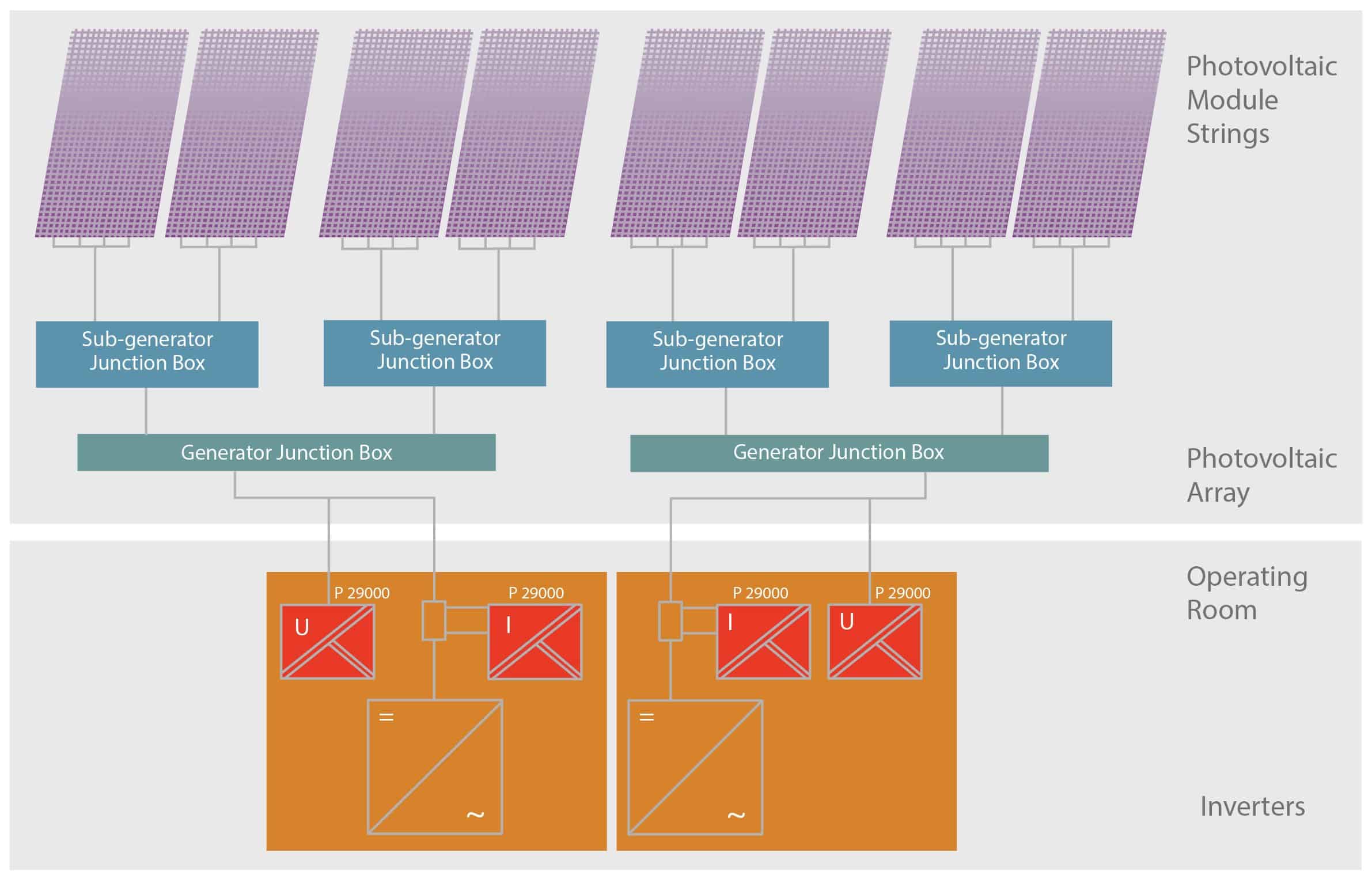

Modern photovoltaic power stations consist of two basic components: the solar modules in the photovoltaic field that convert the sun’s energy into electrical energy and an inverter station that converts the direct current of the solar modules and integrates it into the alternating current grid. Large-scale stations are frequently realized with centralized inverters.

These large inverters have a capacity of approx. 500 kW and modules can be added up to 40-50 MW. Only a few years ago, the fields still yielded a system voltage of 1000 V and currents of several 100 A. Today the majority generate voltages of 1500 V. This is why the corresponding inverters must have a maximum input voltage greater than 1500 V.

Inexpensive and safe monitoring of photovoltaic power stations using specialized signal conditioners

Protection of personnel and the system

Solar power providers face the challenge of ensuring that their system operates efficiently and achieves the greatest possible power yield. In the ideal case, efficiency is increased with little or no extra effort without compromising electrical safety. To trace interference and regulate capacity adjustment, currents and voltages are measured on the DC side. The system voltages indicated above require suitable isolation of the measuring systems in order to protect both the operating personnel and the regulation and evaluation systems.

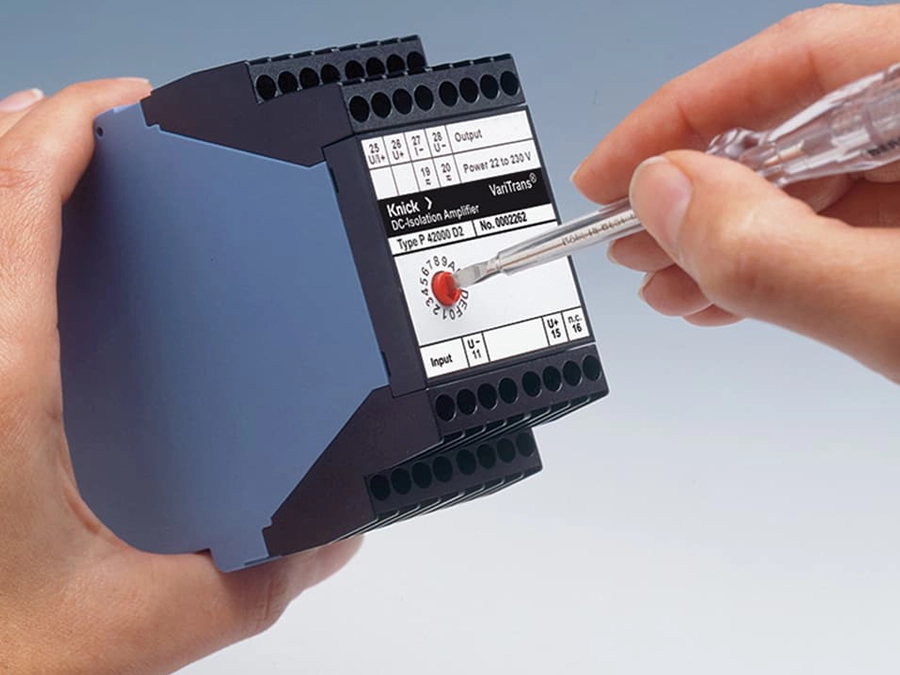

For this reason, measurements are taken via downstream signal conditioners with accordingly high galvanic isolation. In 1000 V stations, protective separation of 1000 V AC/DC is required in accordance with EN 61140.

When the system voltage is raised to 1500 V, the requirements for protective separation become more rigorous. Protective separation is achieved by double isolation that guarantees a safety margin of 100 percent.

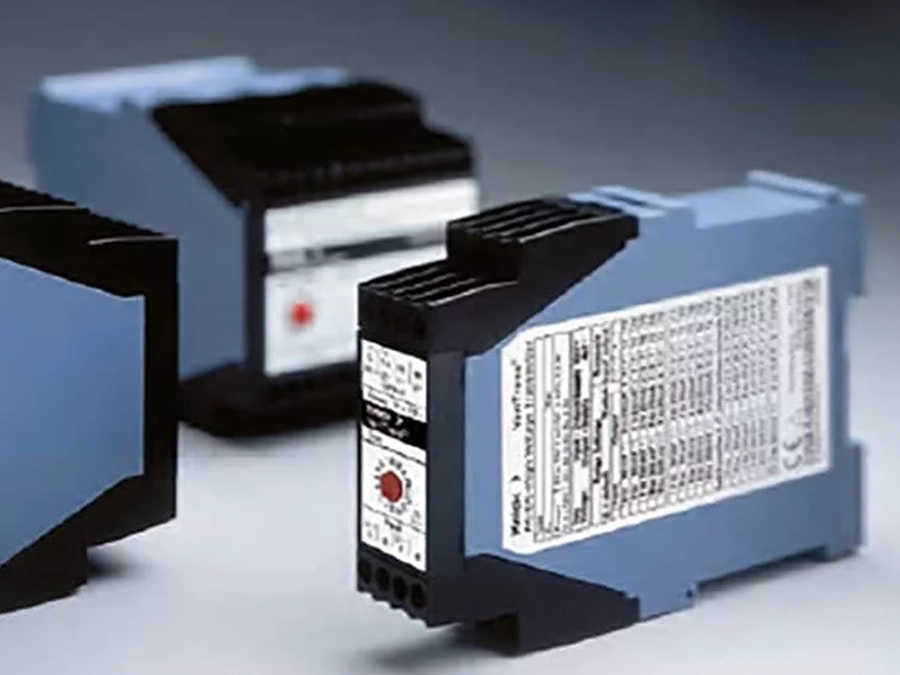

Reliable isolation up to 1800 V

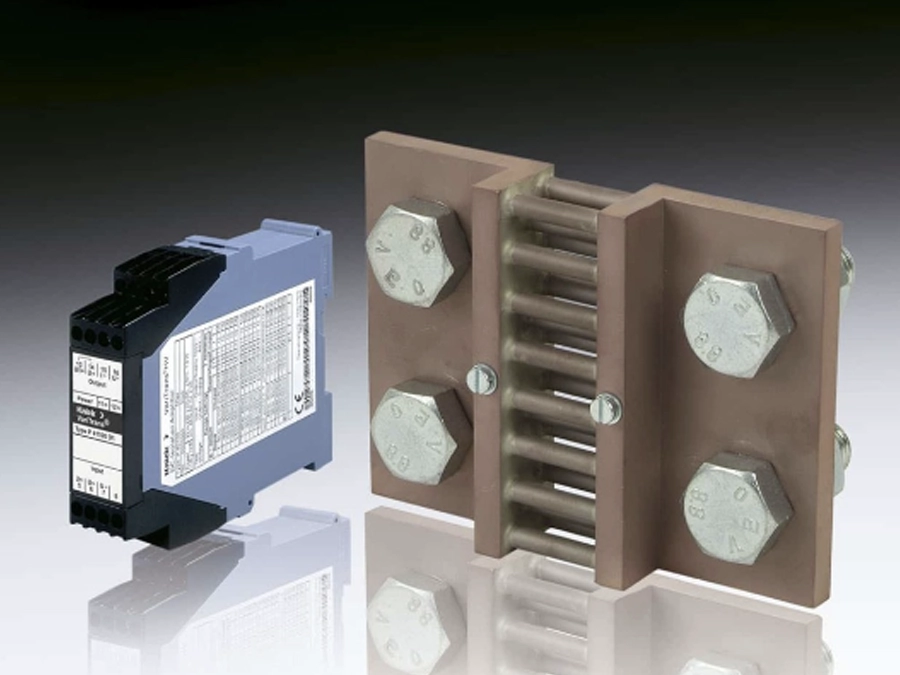

The signal conditioners in the P41000 series (current measurement) and P42000 series (voltage measurement) from Knick establish protective separation up to 1100 V in accordance with EN 61140 (overvoltage category OV III / pollution degree PD 2). In the P41100/ P42100 design, protective separation up to 1800 V AC/DC (OV III and PD 2) is possible. With these signal conditioners, photovoltaic power stations that ensure compliance with the relevant safety standards can be built. With a mean time between failures (MTBF) of 96 years, the products are reliable.

Return on investment

- Current and voltage measuring technology installed centrally in the inverter on the basis of signal conditioners increases efficiency and saves money at the same time since it makes decentralized measurement unnecessary.

- Central signal conditioner arrangement simplifies the station concept development and also results in cost advantages.

- The precise measurement of total current makes it possible to detect defective station components early on, thus avoiding yield losses and increasing the safety and reliability of solar power stations.

- High operational safety with galvanic isolation of up to 1000 V or 1800 V AC/DC

- Calibrated switching of up to 16 input and output ranges offers flexibility and reduces storage costs.

H2 [Ind] [Proc] [App] Application Description

[Ind] briefly: where can be used Knick products [Proc] [App] Detailed application description, why is measured, which customer problem is solved

H3 [App] Initial Situation

Was there a solution before, which was perhaps not good enough? Have requirements changed

H3 [App] Requirements of Application

What were the special or biggest requirements: Operating environment, legal requirements, High Voltage

H3 [App] Solution

Products used and why the solution was implemented in this form