Precise Voltage, Current, and Temperature Monitoring in Electrolyzer and Fuel Cell Systems

Key facts about the application

Sector

Electrolyzer Control & Fuel Cell Monitoring

Application

Voltage, current, and temperature monitoring in electrolyzer or fuel cell stacks and strings

Measured Parameters

DC voltage, current, and temperature to ensure safe and efficient hydrogen production and conversion into electrical energy

Main Requirements

High isolation up to stack/string level, continuous monitoring, long-term stability, safety compliance, no recalibration

High-isolation measurement for stack/string monitoring in H2 applications

As hydrogen plays an increasingly important role in energy storage and transport, maintaining efficiency and safety in electrolyzer and fuel cell systems is more critical than ever. These systems operate at high DC voltages and require accurate, real-time monitoring to function effectively. Continuous measurement at both the stack and string levels supports predictive maintenance and enhances overall system reliability. Knick’s transducers are specifically designed to meet these demands, offering high working isolation that exceeds typical system voltages and delivering the long-term reliability needed to ensure safe, uninterrupted operation.

Description and requirements

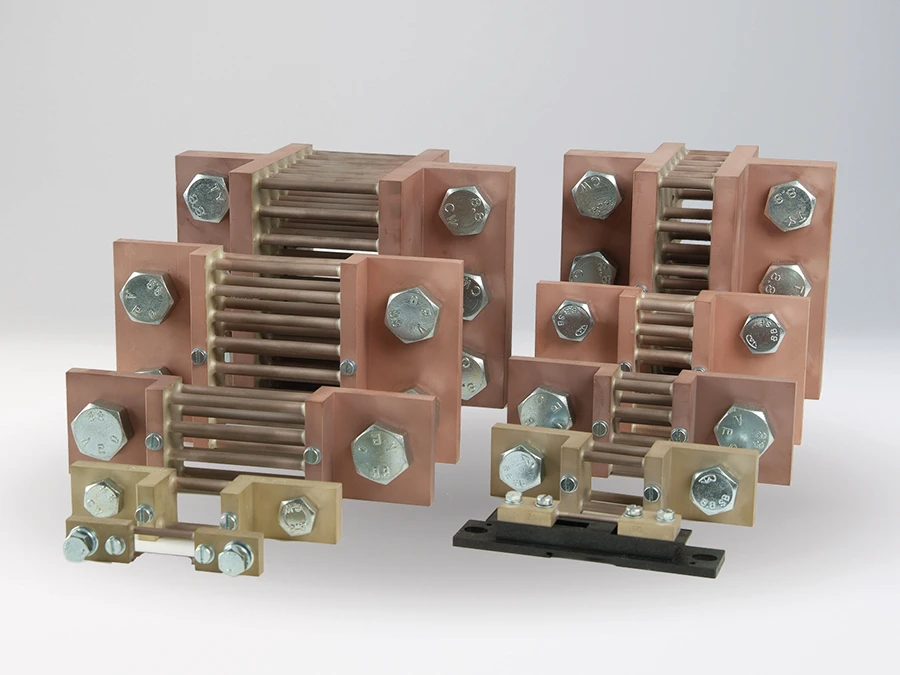

Modern electrolyzers and fuel cells are built by wiring individual cells in series to form stacks, which are then combined into high-voltage strings. While each cell typically operates around 3 V, total string voltages can reach up to 1500 V DC and continue to rise as industry demand grows. To maintain safe and efficient operation, precise monitoring of voltage, current, and temperature at both the stack and string levels is essential for diagnostics and early detection of wear. Without this monitoring, operators risk damaging electrolyzer and fuel cell systems, which can compromise safety and reduce hydrogen production efficiency.

Given the high voltages and potential for voltage surges, measurement equipment must provide strong electrical isolation, not only from the measured signal but also from full system-level potentials. Additionally, the monitoring solution must be durable, maintenance-free, and capable of withstanding environmental stress while ensuring the safety of both operators and equipment.

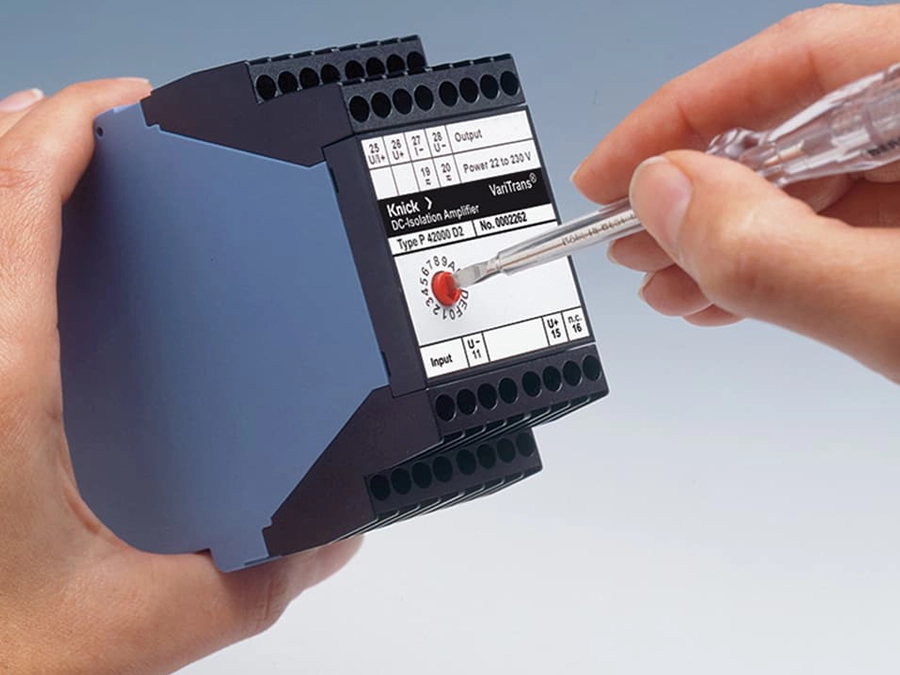

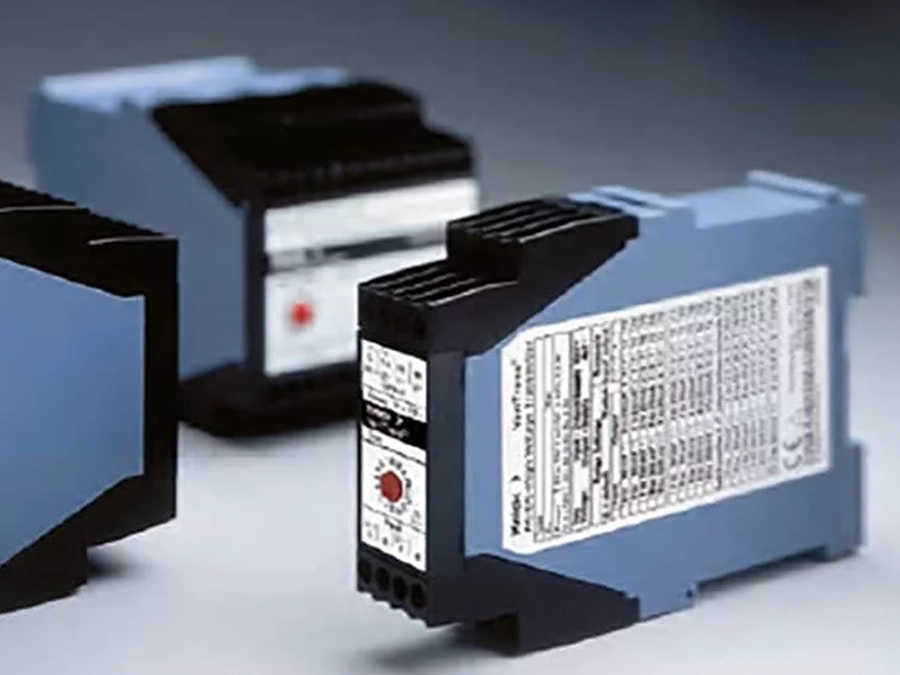

Why Knick ?

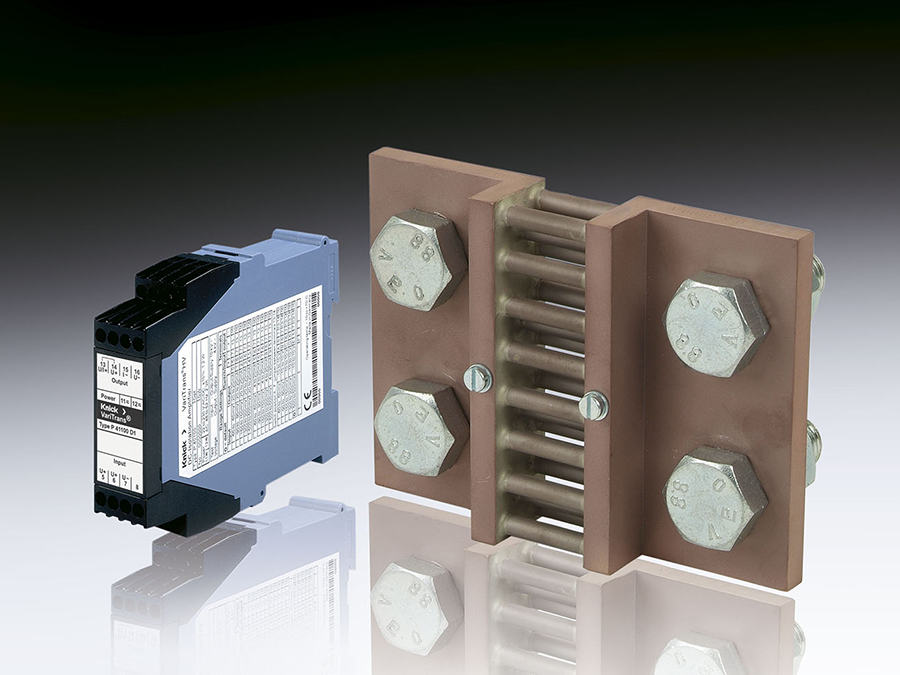

Knick’s transducers deliver high performance measurement with industry leading continuous isolation up to 3.6 kV, exceptional long-term stability, and a compact DIN rail design making them well-suited for integration into electrolyzer and fuel cell systems. They provide accurate voltage, current, and temperature monitoring without the need for recalibration and are supported by a field-proven MTBF rated in the hundreds of years. Built to withstand high potential and noise-heavy environments, these transducers ensure safe, interference free operation. For applications requiring functional safety, Knick also offers SIL rated monitoring solutions to support compliance with evolving hydrogen system standards.

Conclusion

With Knick transducers, operators can reliably monitor electrolyzer and fuel cell performance at both the stack and string levels, enabling early detection of degradation and preventing costly failures. This level of insight supports predictive maintenance strategies, maximizes system uptime, and ensures safe, continuous operation in demanding hydrogen applications.

Knick delivers the clarity and confidence needed for high voltage measurements by combining advanced isolation, long-term stability, and precision. Our commitment to safety, accuracy, and performance makes Knick a trusted partner in the evolving hydrogen energy landscape.