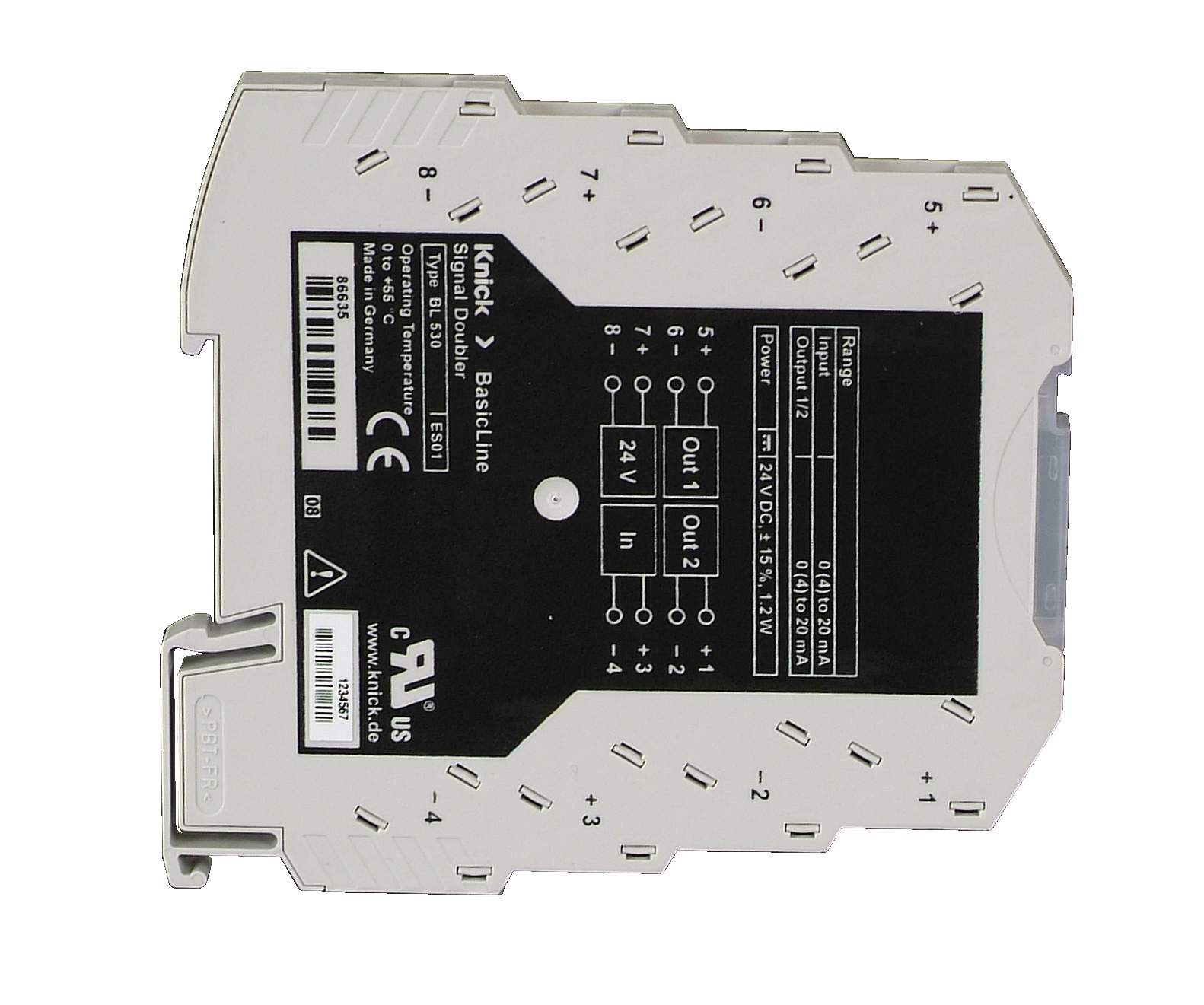

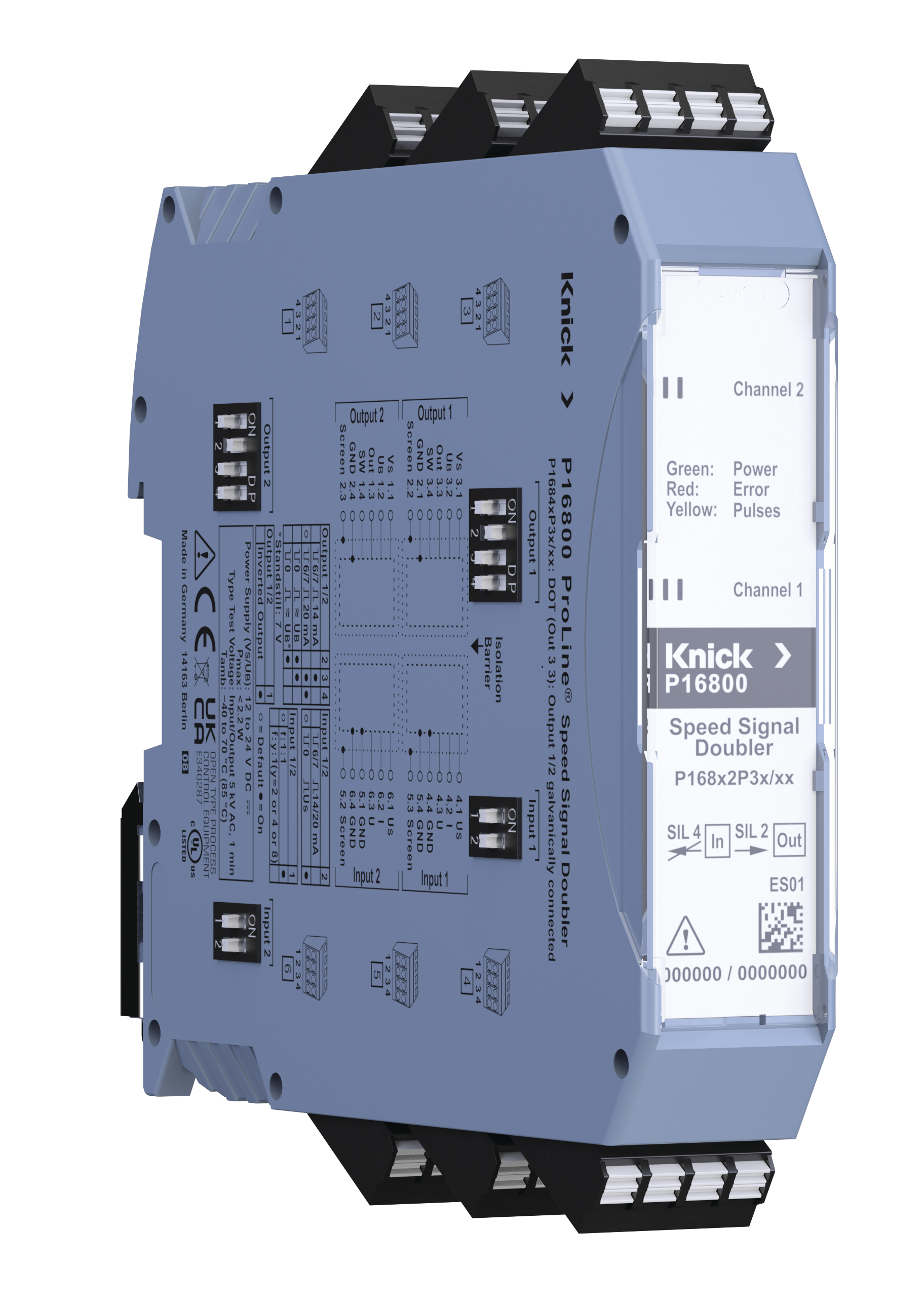

A20340 Standard-signal Multiplier | 6-Port Isolation

Description

Signal multiplier with four calibrated outputs, also for applications with high output loads.

- Safety in the smallest space

6-port isolation in 22.5 mm modular housing - Signal multiplication

combined with signal conversion - Load increase

up to 1000 ohms possible for inputs with high input impedances - Standards-compliant personal protection

through protective separation according to EN 61140 - Precise signal reproduction

thanks to a short response time of T90 = 1 ms, even dynamic signal changes are accurately reproduced - Low-cost solution

only one compact, low-cost device is required instead of four conventional signal conditioners

The A20340 signal multiplier is an extremely compact product that also provides a cost-effective solution to the problem. In this module, the input, all 4 outputs, and the power supply are safely decoupled from one another (six-port isolation).

In addition to “quadrupling” the analog signal, the A20340 is capable of calibrated signal transmission with signal isolation.

We look forward to hearing from you!

Contact Us

| Function: | Decoupled distribution of standard signals |

|---|---|

| Input: | 0 ... 20 mA, 4 ... 20 mA |

| Output: | 0 ... 20 mA, 4 ... 20 mA |

| Isolation AC/DC: | up to 300 V |

| Test Voltage: | 2.5 kV AC |

| Power Supply: | 24 V DC |

| Ambient operating temperature: | 0 … 55 °C |

| Dimensions (W x L x H): | 6.2 x 93 x 101 mm |

| Special features: | All ports galvanically decoupled (6-port isolation), Signal quadrupler with calibrated inputs and 4 outputs, each driving full loads up to 500 ohms |

| Product Category: | Signal Multiplier |

Downloads

Our service

Lorem lorem ipsum ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet. Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod tempor invidunt ut labore et dolore magna aliquyam erat, sed diam voluptua. At vero eos et accusam et justo duo dolores et ea rebum. Stet clita kasd gubergren, no sea takimata sanctus est Lorem ipsum dolor sit amet.