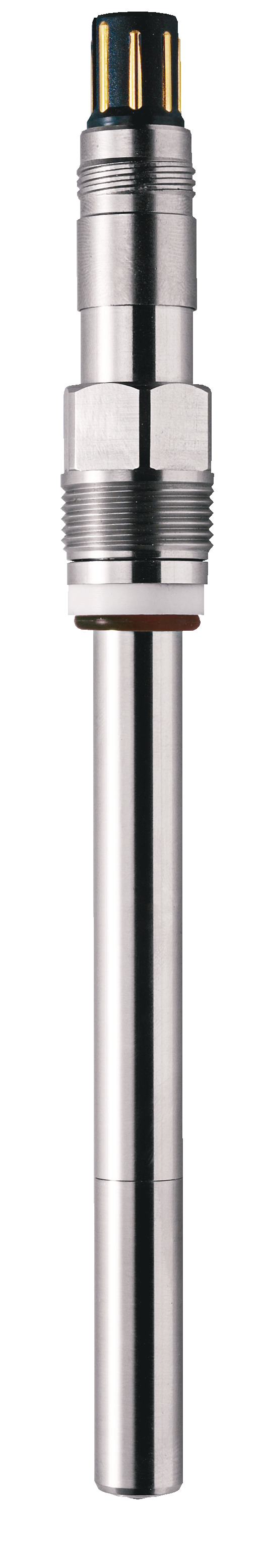

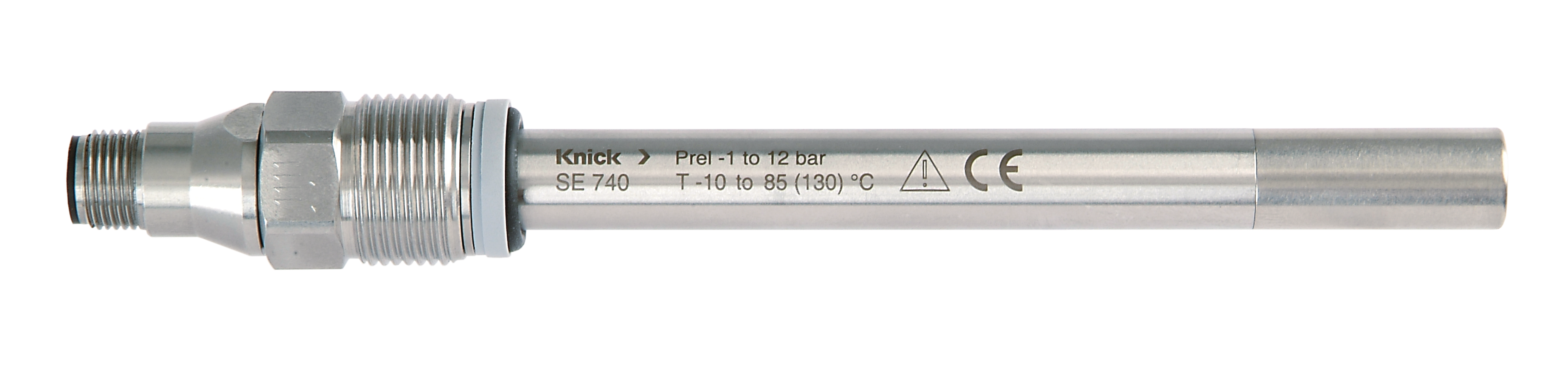

SE706 Oxygen Sensor | VP | 120 mm | Measuring range (resolution) 0 ... 50 mg/l (6 μg/l)

Product number:

SE706/1

Description

SE706 Oxygen Sensor | VP | 120 mm | Measuring range (resolution) 0 ... 50 mg/l (6 μg/l)

Sensor in robust and hygienic stainless steel design, high accuracy and low detection limit, simple and fast maintenance due to special membrane .

- high level of process safety

- durable materials

- robust design

- easy to clean thanks to extremely smooth surface

- cost-efficient service due to easy-to-replace membrane module and interior body

- hygienic design

- high resolution of 6 ppb

- operation also in hazardous locations

- VP screw cap

Reliable in-line measurement of dissolved oxygen, even under sterile and hygienic conditions. High signal stability. Simple maintenance due to modular design. Special membrane with steel mesh and PTFE coating. Sterilizable, autoclavable and CIP capable. Also suitable for use in hazardous locations.

Applications

Biotechnology, pharmaceutical industry, fermentation, various fields of analytical chemistry

We look forward to hearing from you!

Contact Us

| Measurement Parameter: | Oxygen |

|---|---|

| Permissible pressure range (measurement): | 0.2 ... 6 bar absolute |

| Length: | 120 mm |

| Connector: | VP (VarioPin) |

| Measuring Range: | pO₂ < 1,200 mbar |

| Process Connection: | PG 13.5 |

| Temperature Detector: | NTC 22 kΩ |

| Measuring principle: | Amperometric |

| Membrane material: | PTFE / silicone / PTFE, FDA compliant (steel-mesh reinforced) |

| Flow dependence: | ≤ 5 % |

| Signal Transmission: | analog |

| Mechanical pressure resistance: | Max. 12 bar absolute |

| Temperature range (stability): | –5 ... +140 °C (steam sterilizable/autoclavable) |

| Accuracy: | 1 % + 4 ppb |

| Signal in ambient air: | 50 ... 110 nA |

| Response time at 25 °C (air –> N2): | 98 % full scale < 90 s |

| Residual signal in O₂-free medium: | ≤ 0.1 % of signal in ambient air |

| O-ring material (process-wetted): | silicone (FDA & USP Class VI tested) |

| Process-wetted sensor parts: | Stainless steel 1.4404 (material certificate 3.1B) |

| Surface roughness: | N 5 (RA < 0.4 μm) |

| Interior body incl. electrodes: | replaceable (ZU 0567) |