Electrical safety in factory-side test cells

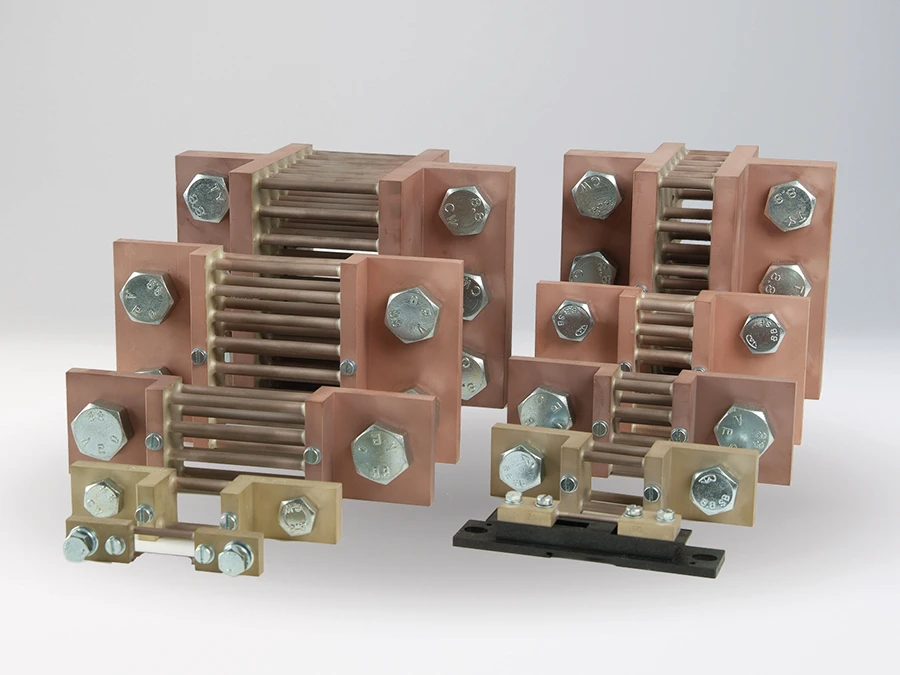

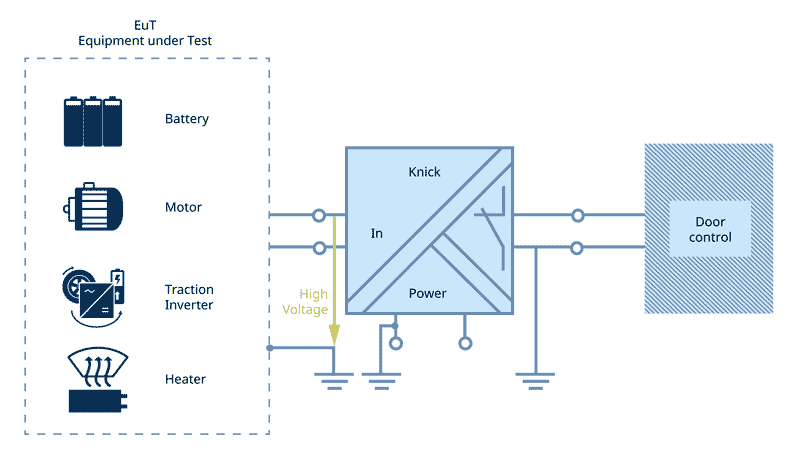

High voltage components like batteries, power electronics, heaters, and electric axle drives must be checked for function and safety before they are installed in vehicles. To ensure that the procedure is safe, the test cells used in the manufacturing process often have a protective enclosure to prevent hazards to persons located in the vicinity of the system.

Key facts about the application

Sector

Electrical safety in factory-side test cells

Application

Reliable confirmation that high voltage is no longer applied

Measured parameters

Switching threshold-based output signal, as soon as a user-defined threshold value is reached.

Main requirements

Ensuring occupational safety in high-voltage environments

Precise sensor detection of unsafe voltage limits

Confirmation of system operation

Safety through detection of dangerously high voltages

Description of application

The test stations must be protected in accordance with EN 50191 (or similar standards and safety stipulations of the country in which the system is to be installed).

Requirements of the application

Since the qualification process for components typically includes tests under load, reliable confirmation that high voltage is no longer applied is a key prerequisite for permitting personnel to safely enter the test cells again.

Why Knick?

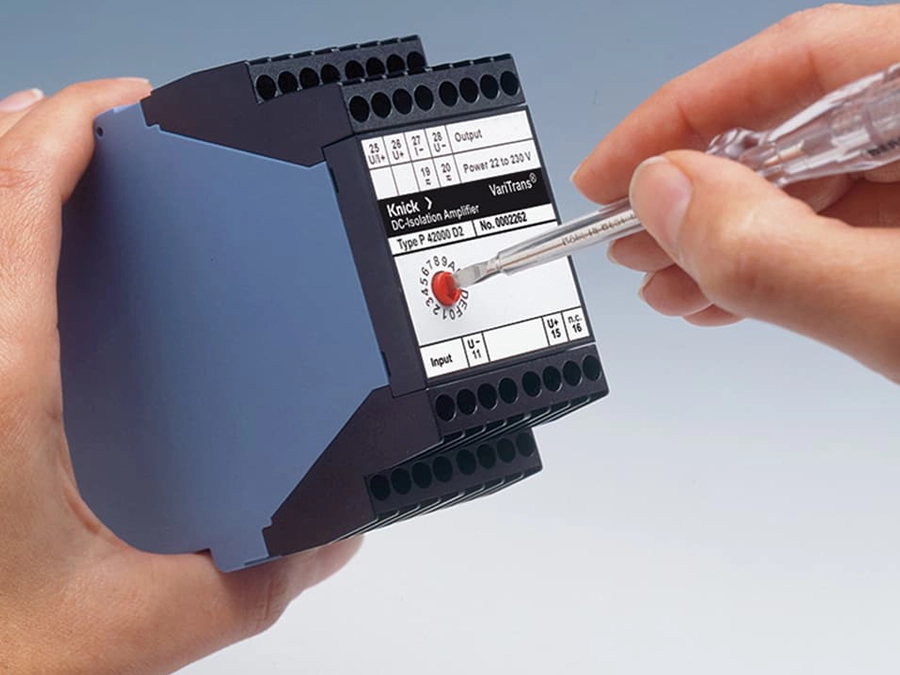

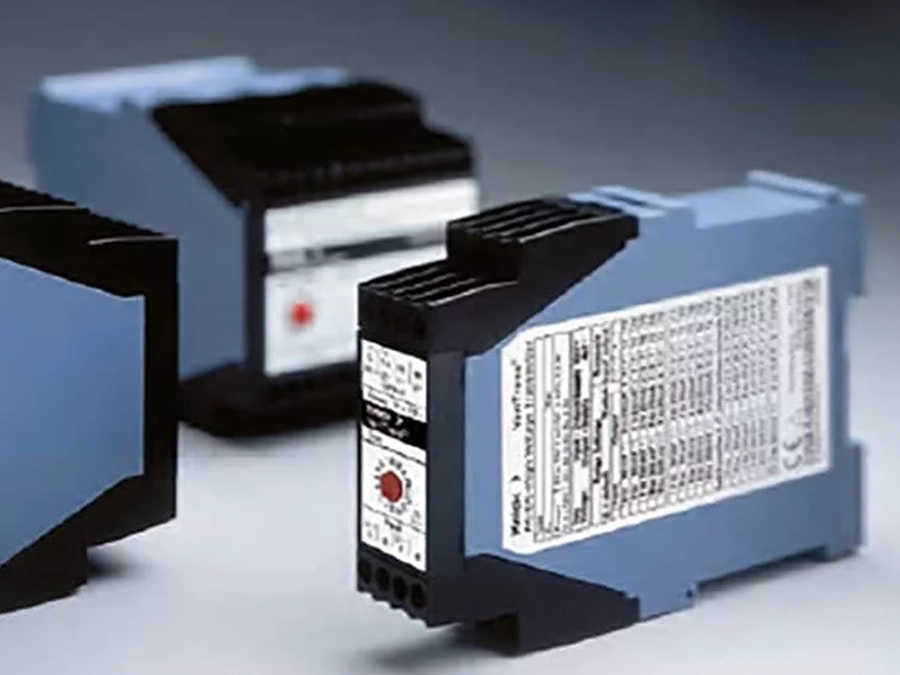

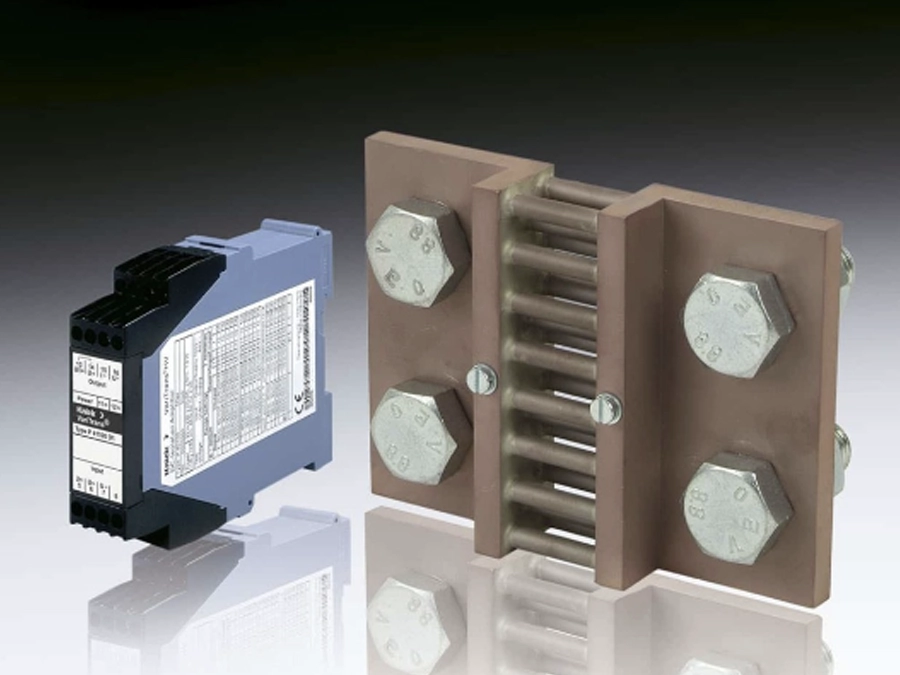

The robust P52000VPD sensor from Knick supplies a switching threshold-based output signal as soon as a user-defined threshold value has been reached. Voltage monitoring via voltage presence detector is possible up to ± 4200 V AC/DC and continuous isolation up to 4800 V AC/DC. An available diagnostics buffer switch output confirms the “Power good” state. The device housing with protective cover made of hardened carbon fiber protects against high voltage at terminals.

Matching products

Associated industries and applications

Overview of measuring technology applications and product solutions for electromobility