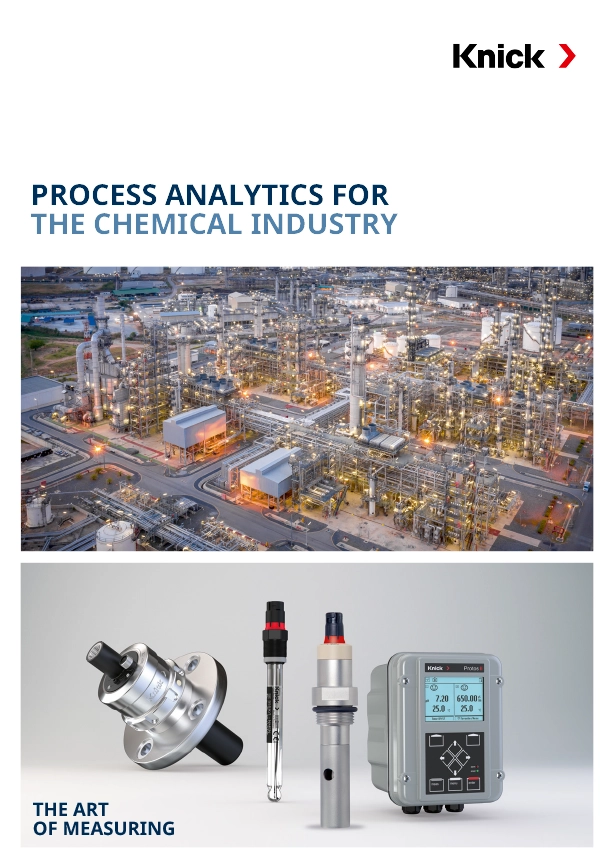

Ready for the Toughest Requirements in the Chemical Industry

Knick is known for its robust, durable products that also withstand harsh environmental and measuring conditions. Co-developed and launched by Knick, contact-free Memosens technology contributes to this reputation. The combination of durable products and digital Memosens technology ideally matches the requirements of the chemical industry.

Broad Range and Demanding Requirements

The chemical industry encompasses an extremely broad range of applications. The ambient conditions can be wet, highly corrosive, and toxic. For this reason, process reliability plays a key role in conjunction with explosion protection and proven measuring technology. Measured values for pH, for example, are often extreme (pH < 1, pH > 13) and go hand in hand with increased temperature and pressure. This places rigorous demands on the sensors. The range of corrosion-resistant special-purpose materials (Hastelloy, titanium, PEEK, and Teflon) is as indispensable as fittings designed specifically for the application.

Outside Europe, measuring technology is often installed outdoors, which requires particularly robust measuring technology with housings made of coated stainless steel or plastics resistant to corrosion, shocks, and UV light, for example.

Is your measuring loop subject to other conditions? No problem! With our product range, we can offer you the optimal solution for almost any measurement task.

Basic Chemicals

Nutrients

Fine & Specialty Chemicals

Dyes & Pigments

Why Knick?

Even when measurement tasks have special requirements, Knick is ready for the challenge!

With a combination of suitable products that can be configured to meet your individual needs, we offer you the right solution for your measurement task: with manually operable retractable fittings or the fully automatic cCare cleaning and calibration system, for example.

Knick starts where others stop.

Overview of specific applications and product solutions in different areas of industrial chemicals.

Related Applications

Do you have more questions? We are here for you.

Contact us!