DC voltage measurement for interfaces between vehicle and charging station

For battery electric commercial vehicles, there is a quick-charging option via pantographs. This requires a contact between an external infrastructure system (with movable pantographs) and permanently installed charging rods on the vehicle roof. What speaks the most in favor of this method is that they can supply the vehicle with sufficient power without long charging breaks and keep it in operation: a significant advantage for road vehicles like city buses. Typically, there are several charging points for pantographs at different points along the vehicle’s route.

The higher the direct current of the pantograph system, the faster the vehicle can be charged. For this reason and for higher drive outputs, the tendency is to choose higher and higher voltages. Forecasts assume expected voltages of over 2000 V DC. Of course the technology for monitoring and isolating these voltages must keep pace with the evolving demand.

Key facts about the application

Sector

DC voltage measurement on-board systems for pantograph charging

Application

Checking the charging connection and connection to other on-board systems

Measured parameters

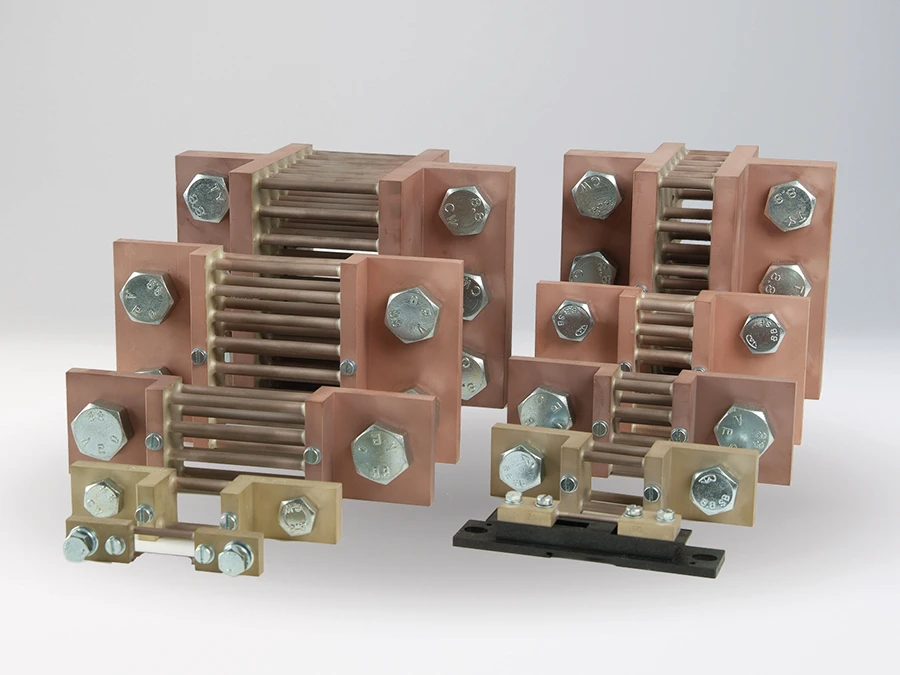

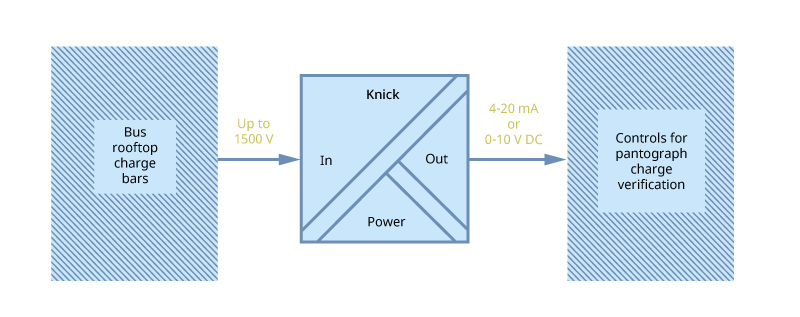

Voltage up to 1500 V DC, output standard signal 4-20 mA or 0-10 V DC

Main requirements

Compact measuring modules, footprint is one of the main criteria

The reliability of the voltage measurement plays a key role in ensuring vehicle availability

Protective separation of high voltages; necessary for protection in public transport

On-board systems for pantograph charging

Description of application

A DC roof container contains components that check the charging connection and the corresponding voltage, and establish the connection to the other on-board systems.

Requirements of the application

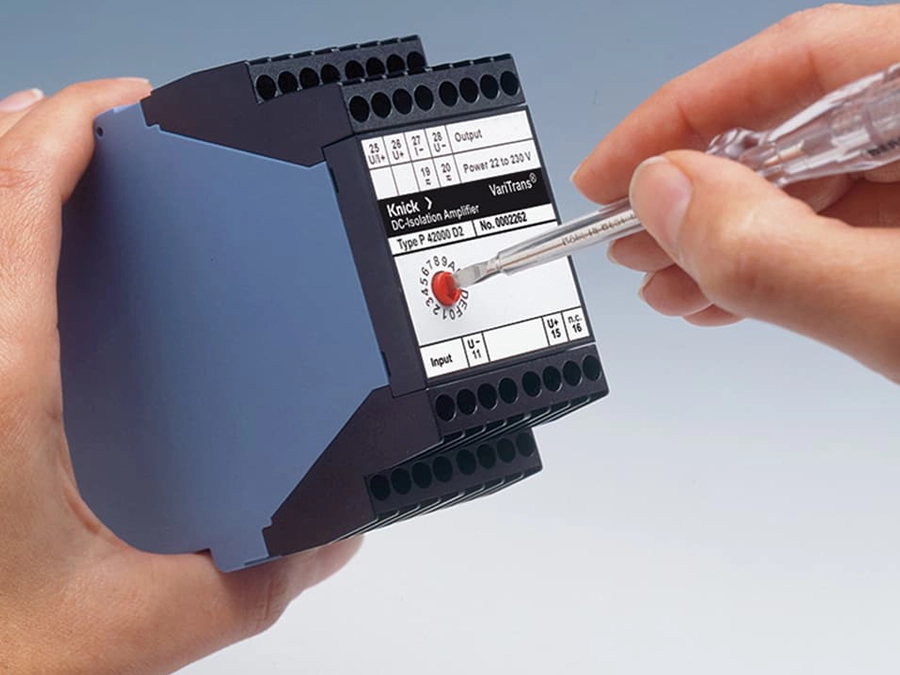

With the limited space in the DC roof container, the solution for voltage monitoring and isolation must be performant, reliable, and compact.

Why Knick?

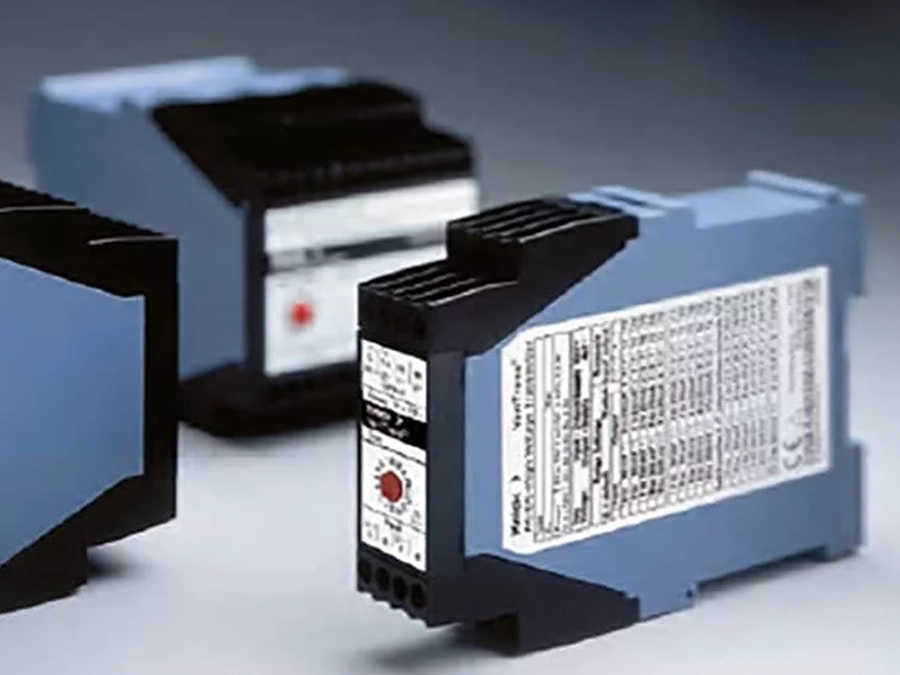

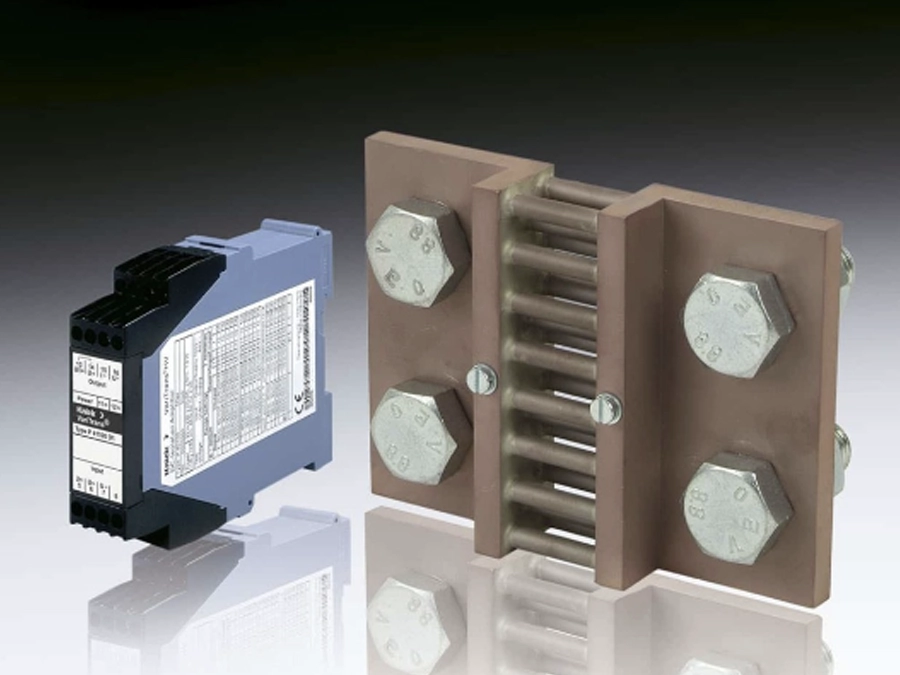

P42000D2 is a compact high voltage transducer for voltage measurement and continuous isolation up to 2200 V AC/DC. With a housing width of only 45 mm, it is perfect for applications in small spaces. Measurement quality is ensured by a gain error of < 0.3 %, a response time T90 of 110 μs, and a cutoff frequency of 5 kHz.

H2 [Ind] [Proc] [App] Application Description

[Ind] briefly: where can be used Knick products [Proc] [App] Detailed application description, why is measured, which customer problem is solved

H3 [App] Initial Situation

Was there a solution before, which was perhaps not good enough? Have requirements changed

H3 [App] Requirements of Application

What were the special or biggest requirements: Operating environment, legal requirements, High Voltage

H3 [App] Solution

Products used and why the solution was implemented in this form

Matching products

Associated industries and applications

Overview of test and measurement specific applications and product solutions in e-mobility