PROCESS ANALYTICS

Flue Gas Scrubbing in Sludge Incineration

Flue Gas Scrubbing in Sludge Incineration

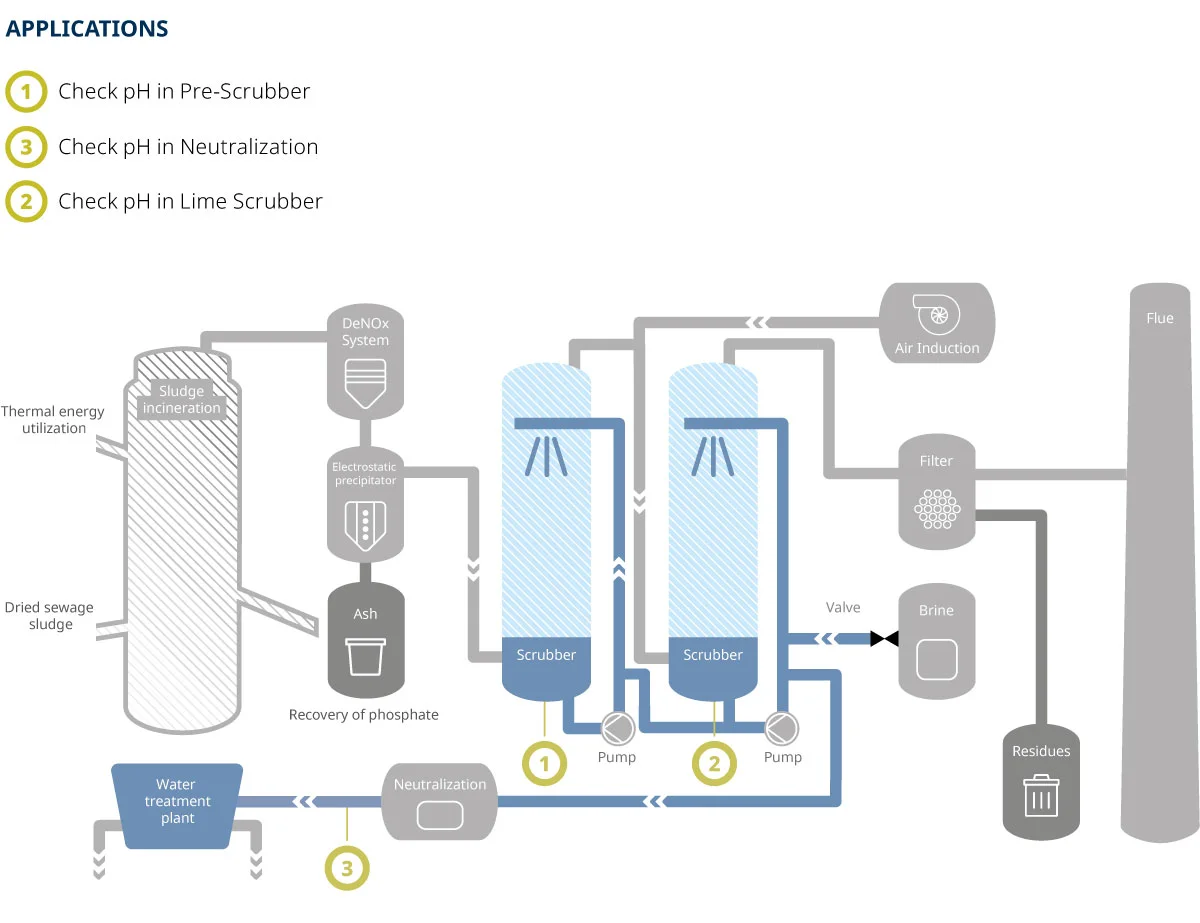

Toxic sludge that must be treated for phosphorus recovery is produced in biological wastewater treatment plants. Phosphorous can be recovered from the ashes of incinerated sludge.

The harmful gases released when the sludge is incinerated are bonded in a wet flue gas scrubber. The raw water this yields is neutralized by the addition of a caustic soda solution.

An appropriate dosage of caustic soda solution requires both pH measurements in the raw water and conductivity measurements of the caustic soda solution to determine the concentration.

As a multi-channel transducer that can monitor multiple measuring loops at the same time, the Protos industrial transmitter in conjunction with the Memosens SE656 andSE555 sensors ensure reliable process control.

Raw Water Treatment After Flue Gas Scrubbing

Sludge that mostly consists of feces-consuming microorganisms remains in modern biological wastewater purification plants. The sludge also contains toxic admixtures such as heavy metals, halogenated hydrocarbons, and pathogens, which argues against composting or agricultural use as fertilizer. With the German Reform of Sewage Sludge Utilization, phosphorus recovery became mandatory in Germany. Phosphorous can be recovered from the ashes of incinerated sludge.

The energy gained during incineration can be used to generate electricity for centrifuges, pumps, etc. and the waste heat can be used to dry sludge. But incinerating sludge releases harmful gases that must not be emitted into the environment. After denitrification or the removal of nitrogen oxides, the wet flue gas scrubbing process ensures that the remaining contaminants are separated. The flue gas is guided against sprayed water in counterflow principle, and the gaseous contaminants are bonded to the aqueous phase. The resulting raw water has a pH value of approx. 2.

In the second scrubbing step, caustic soda solution is added in order to bond the malodorous gases, most of which are sulfur compounds. Here, the pH value must not drop below 7. Since multiple scrubbers are typically used in close proximity, multi-channel devices for pH monitoring offer many economic and practical advantages.

Safe Process Control and Maximum Flexibility with Protos

Since multiple measuring loops can be realized with only one transducer in the Protos series, these industrial transmitters have proven to be outstanding in the flue gas scrubbing process.

In simple cases, the caustic soda solution can be metered via Protos relay contacts. In the basic variant, the modular transducers have four relay outputs, which is the minimum requirement for 2-channel measurement.

If necessary, the number of outputs can be doubled with an output extension module. The modular structure of Protos gives users maximum flexibility in all matters. Previously single-channel measuring loops can be operated as 2-channel loops by plugging in an additional module. Other modules for additional contacts, current outputs, or control functions (PID) permit simple, needs-compatible retrofitting at any time.

More Effective Maintenance Options with Memosens Sensors

To determine the concentration of the caustic soda solution, conductivity is measured with the SE656 inductive sensor. The sensor with high chemical resistance was developed especially for highly contaminated and highly oxidizing media. For pH measurement of the alkalization in scrubbers, which have permanent pH values of 12, Knick recommends using the Memosens SE555 pH glass electrode, which achieves a service life of approx. 6 months.

The option of pre-calibrating Memosens sensors in the laboratory eliminates the need for difficult on-site calibration. Despite the complicated measures, the impact of the odor would be unacceptable to personnel in the immediate process environment. For this reason, the buildings are purged with fresh air and the ventilated, polluted air is cleaned in a final, alkaline wet scrubbing process.

The scrubber water cannot be reused in the sewage treatment plant without damaging the biological stages of the plant until it is neutralized in a final step that requires additional pH measurements.

Return on Investment

- Long service life of Memosens pH sensors

- Implementation of multiple measuring loops with only one Protos transducer

- The unique modular concept of Protos permits easy adaptation to changing measurement requirements at any time.

- Optional full automation of measuring loops that are difficult to access reduces service effort.

- The option of metering the caustic soda solution with Protos eliminates the need for additional controllers.