PROCESS ANALYTICS

Industrial Wastewater Treatment

Industrial Wastewater Treatment

In Germany, industrial wastewater treatment is subject to the strict provisions of the Waste Water Ordinance (Abwasserverordnung). In the worst case, improper, inadequate treatment can lead to the shutdown of the entire treatment plant until the deficiencies are remedied.

Treating industrial wastewater involves more than complying with environmental regulations: Facilities with high water consumption lower their expenditure on raw materials by treating and re-using their wastewater.

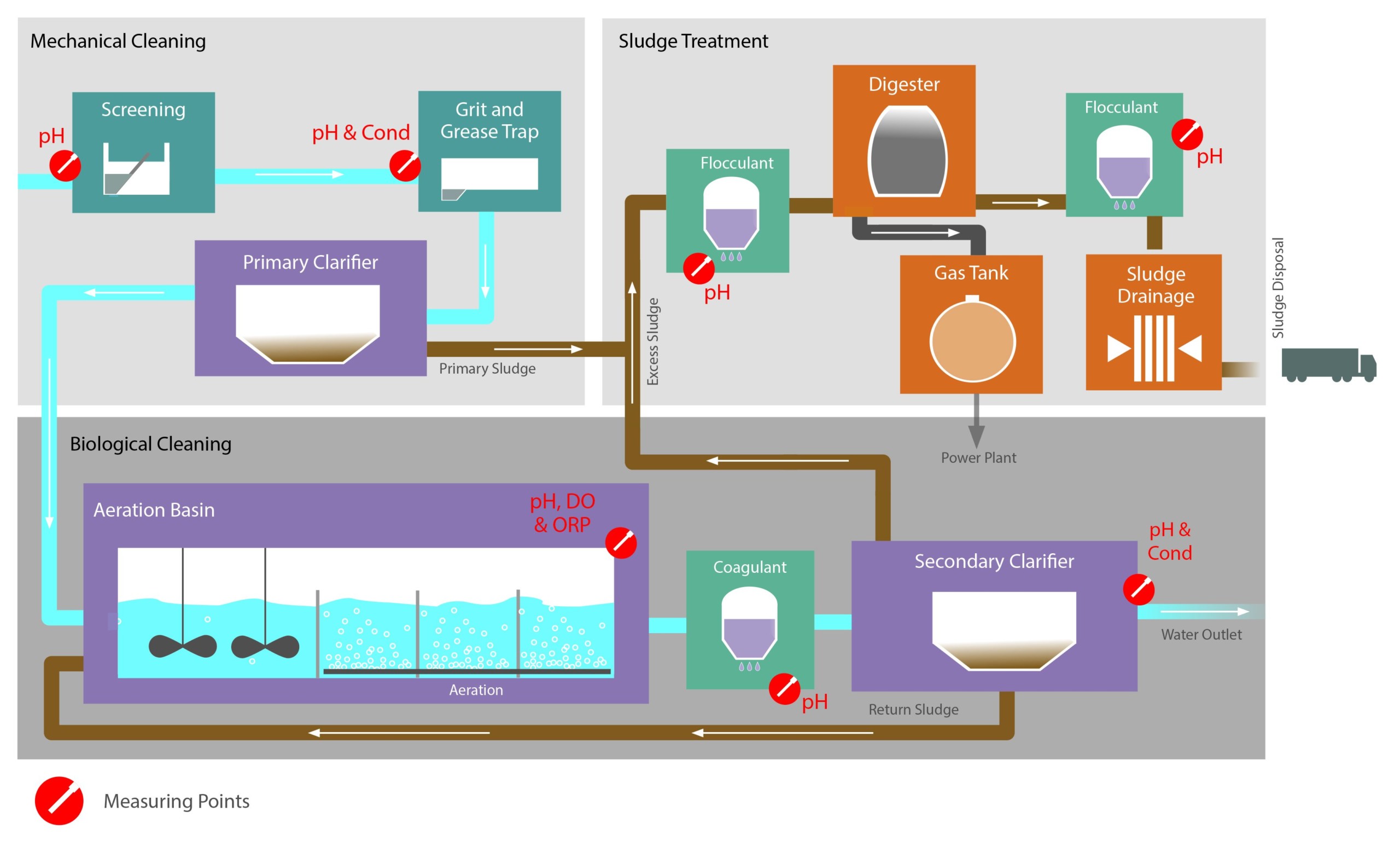

In the case of organic wastewater treatment in particular, pH values, redox potential, and dissolved oxygen must be accurately measured in order to ensure the optimal metabolism of the bacteria used in the purification process.

pH, ORP, and Oxygen Measurement for Environmentally Compatible Wastewater Treatment

Contaminants Determine the Purification Method

Industrial wastewater is different from the process water of private households in that it is contaminated with substances that decompose with difficulty. Depending on the industry, they could be heavy metals, grease, oil, alkaline substances, or as in the case of paper or soap production, for example, even organic substances that involve increased effort to neutralize or separate.

Alongside mechanical filtration methods, they are purified with thermal processes and the support of microorganisms.

pH Measurements to Protect Plants and Bacteria

Depending on the degree of contamination, wastewater with organic content undergoes various purification processes, including flocculation and precipitation. In flocculation, the goal is to have the dissolved contaminants clot and form flakes that can be filtered, while precipitation has the goal of restructuring the contaminants into heavier compounds that drift down to the bottom. If the wastewater cannot be classified as harmless after these treatments, bacteria convert the remaining contaminants into combustible or recyclable biomass in aeration tanks.

The process water or cleaning water from food and beverage production facilities or fermentation processes has highly variable pH values depending on the application. Since low pH values can lead to damage to plant parts as well as killing bacteria, acquiring the pH values in the supply lines is a timely countermeasure. The pH values can either be neutralized with chemical additives or if necessary, the wastewater feed into clarification tanks can be interrupted.

Thanks to its design for extreme pH values, the Memosens SE554 sensor is ideal for monitoring wastewater in the food industry. It is made from Alpha Glas in order to ensure fast, stable sensor reaction. The polymer electrolytes make direct contact through an open junction, which reliably prevents problems caused by clogging and blockages in highly contaminated media.

Smooth Underwater ORP and Oxygen Measurement for Ventilation Control

Redox potential is an important parameter for the efficient ventilation of the aeration tank: In conjunction with other process variables, it provides key information about the ratio of oxygen content to bacteria activity. As a sum parameter, ORP does not indicate absolute quantities of substances. Instead, its continuous measurement permits the observation of changes in concentration over time. Comparing concentration trends to other values yields a basis for controlling tank ventilation, with which maximum efficiency of aerobic or anaerobic metabolism phases can be achieved. Experience has shown the most meaningful measuring results come from the upper 25 percent of the water in the tank.

Because the measuring electrodes must be immersed for this, the Memosens SE565 sensor for ORP measurement has proven its worth. Thanks to their inductive transmission of supply voltage and digitized measured values, all Memosens sensors can be used under water problem-free. And SE565 is also suitable for use in aggressive or highly contaminated media, and media containing sulfides or proteins. To ensure that the aerobic microorganisms have an adequate supply of oxygen, absolute measurements of dissolved oxygen concentrations are also necessary. With SE715, an inexpensive Memosens sensor is available for the simultaneous measurement of dissolved oxygen and temperature. It was specially designed for aeration and ventilation control in wastewater treatment plants. Alongside long-term stability and quick sensor reaction, its most outstanding feature is low flow dependence.

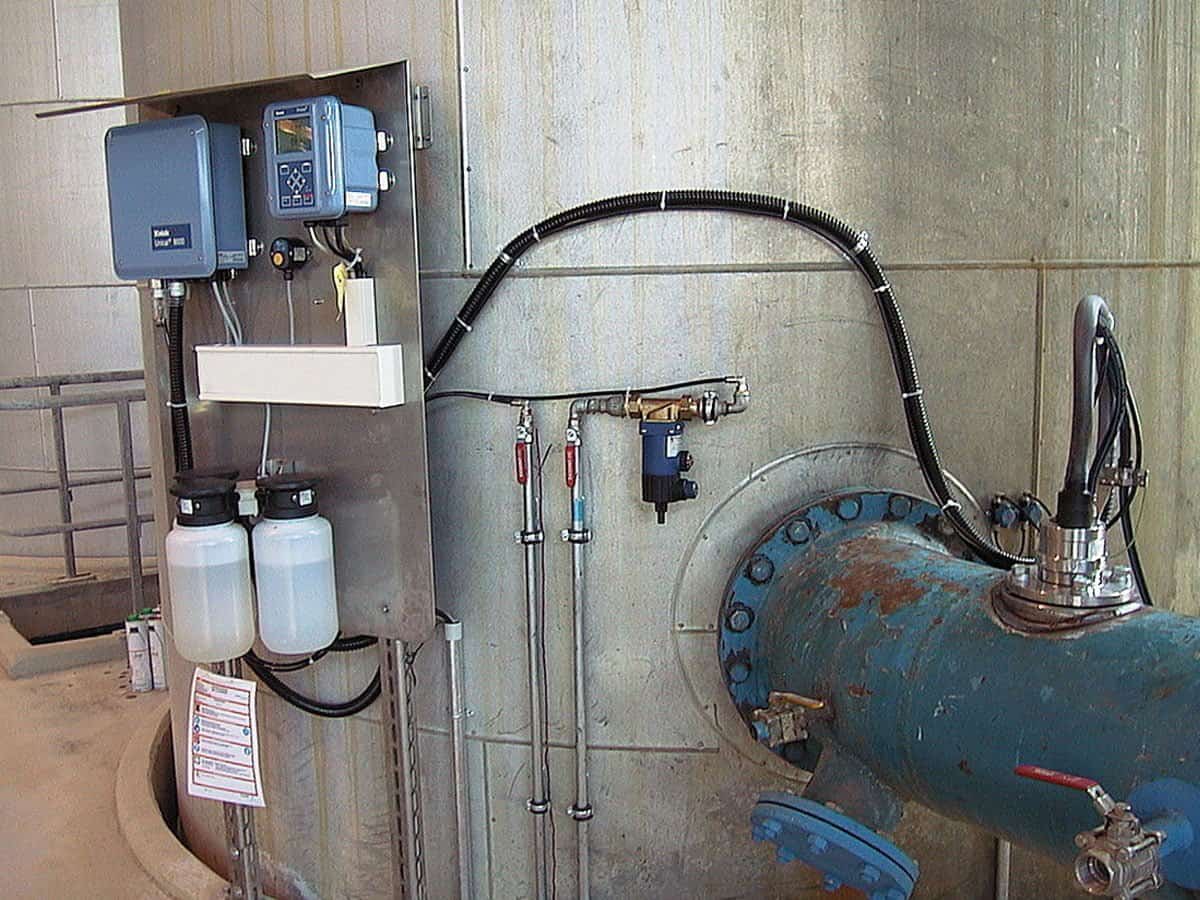

Safe Measurements with Custom Fittings

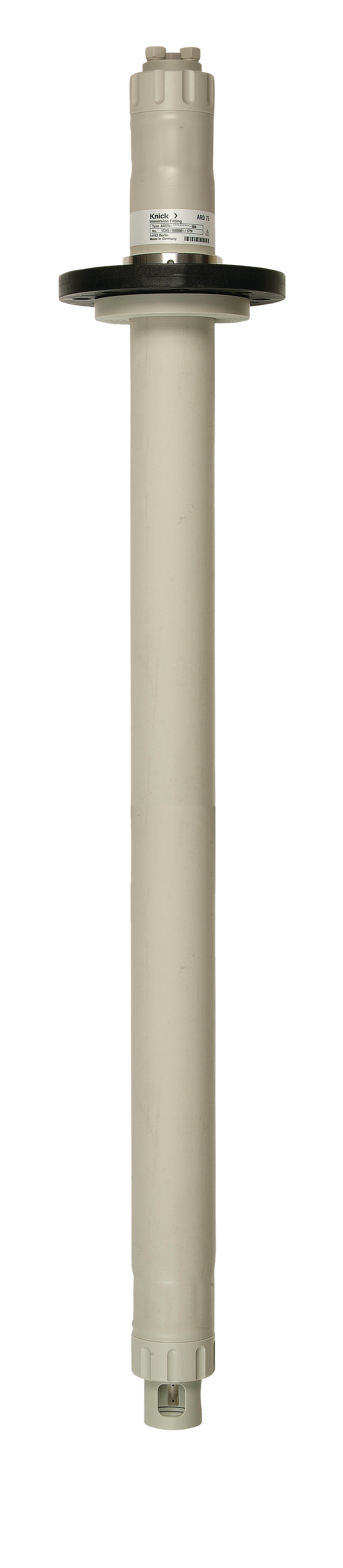

As an advantage in open tanks, the sensors can be integrated into the process using immersion fittings. In the ARD75 immersion fitting, up to three 12 mm sensors (pH/ORP, conductivity, and oxygen) can be mounted together. Fast sensor replacement with sensors pre-calibrated in the laboratory and the integrated rinsing function for cleaning the sensors support their suitability for use in wastewater treatment plants.

Return on Investment

- Thanks to inductive, waterproof Memosens plug-in connections, the sensors can be immersed directly at the desired measuring point in order to measure pH values, redox potential, and dissolved oxygen without any additional equipment.

- Eliminating the need for conventional process connections significantly reduces costs and the time required for sensor replacement.

- The high quality of measurements below the surface and the reliability of Memosens sensors with long-term stability improve process quality.