过程分析

原奶交货质量控制

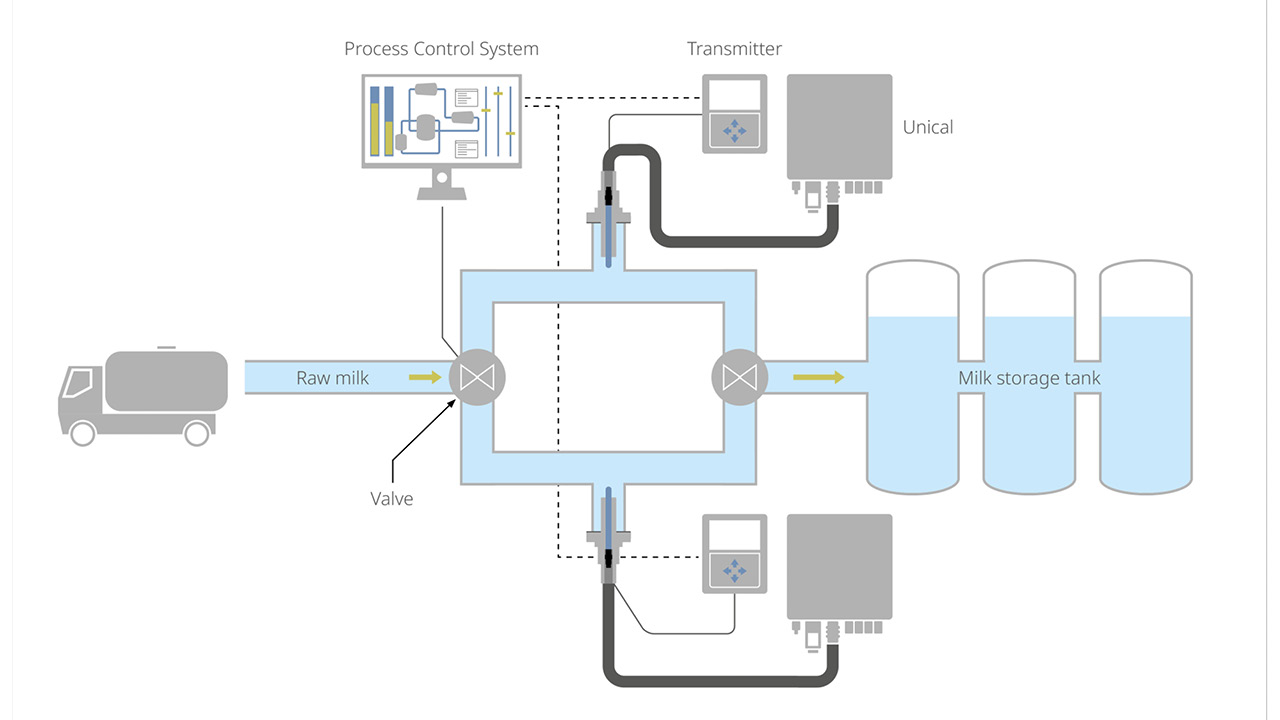

昼夜不停给乳品厂提供原奶。原奶需要满足高质量要求,因此必须在线监测卡车的卸货过程。如果将劣质原奶(酸奶)装入储罐中,全部牛奶库存都会变质。

主要应用概况

领域

乳品厂

应用

在线监测卸货过程

测量参数

pH 值

主要要求

在线测量,自动清洁和校准传感器,确保全天候可用

发生故障时发出警告/警报,从而立即停止将原奶泵出到储罐中。

满足所有卫生要求,如 CIP 和 SIP

在原奶中测量

应用说明

原奶质量对乳制品质量有决定性影响。鲜奶的 pH 值为 6.5 至 6.7。牛奶中的乳酸菌会将乳糖转化为乳酸,这主要取决于温度。如果牛奶呈酸性,则 pH 值较低,而 pH 值高于 4.5,牛奶就会凝结。因此,测量 pH 值非常适合于直接在交货时控制质量。

应用的要求

在乳品厂交付牛奶时,必须进行 pH 测量,以防止污染整个储罐。与食品工业领域的所有应用一样,其要求特别高:除了精确测定 pH 之外,传感器也必须适用于常见的 CIP 和 SIP 过程。在此类过程中进行清洗和灭菌,让清洗和冲洗溶液以及热蒸汽通过封闭的系统。

为何选择 Knick?

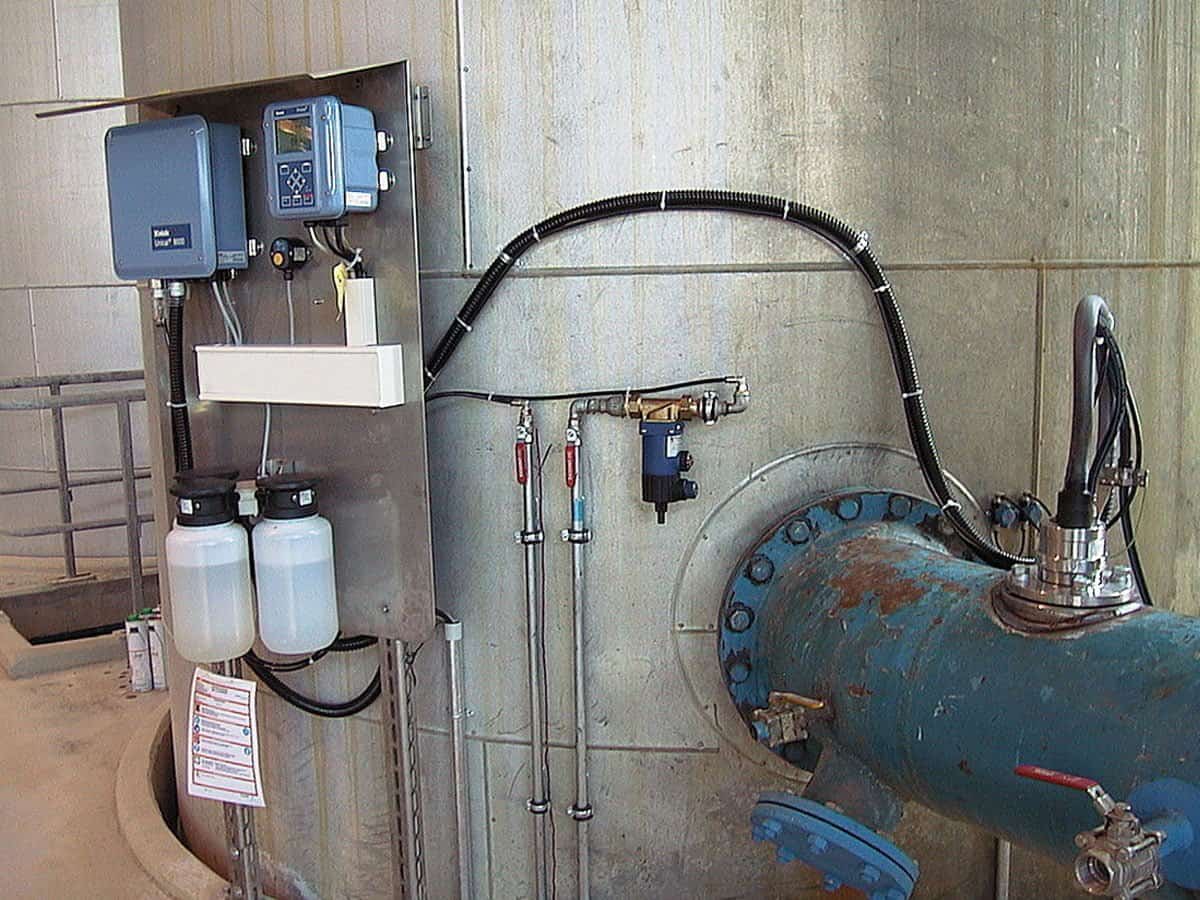

高质量的 pH 传感器与合适的工业变送器相结合,可以直接在卸货时检查原奶的质量。连接到上位系统后,如果 pH 值太低,就会立即停止卸货过程。这样就能有效避免污染整个储罐。采用自动清洁与校准系统以及带传感器护套的伸缩式连接件,无需费时拆卸和更换传感器。因此,测量回路的可用性高,维护人员需求少。

相关产品

相关工业和应用

Knick offers a solution to extend the life of pH sensors that are susceptible to wear, especially with difficult media: cCare ensures accurate measured values through fully automatic cleaning and calibration of pH sensors while reducing maintenance and material costs.