过程分析

监测饮用水处理装置的原水供应

在饮用水处理装置中,对所使用的原水进行质量检查至关重要。市政饮用水处理预算通常不高。

因此,工厂运营商面临在遵守严格成本核算的情况下实现清洁饮用水安全生产过程的挑战。

在线测量 pH 值和氧化还原电位 (ORP),有助于饮用水处理设备运营商评价所供原水的质量,并采取保护设备的措施。

在饮用水处理装置中进行 pH 和氧化还原测量的重要意义

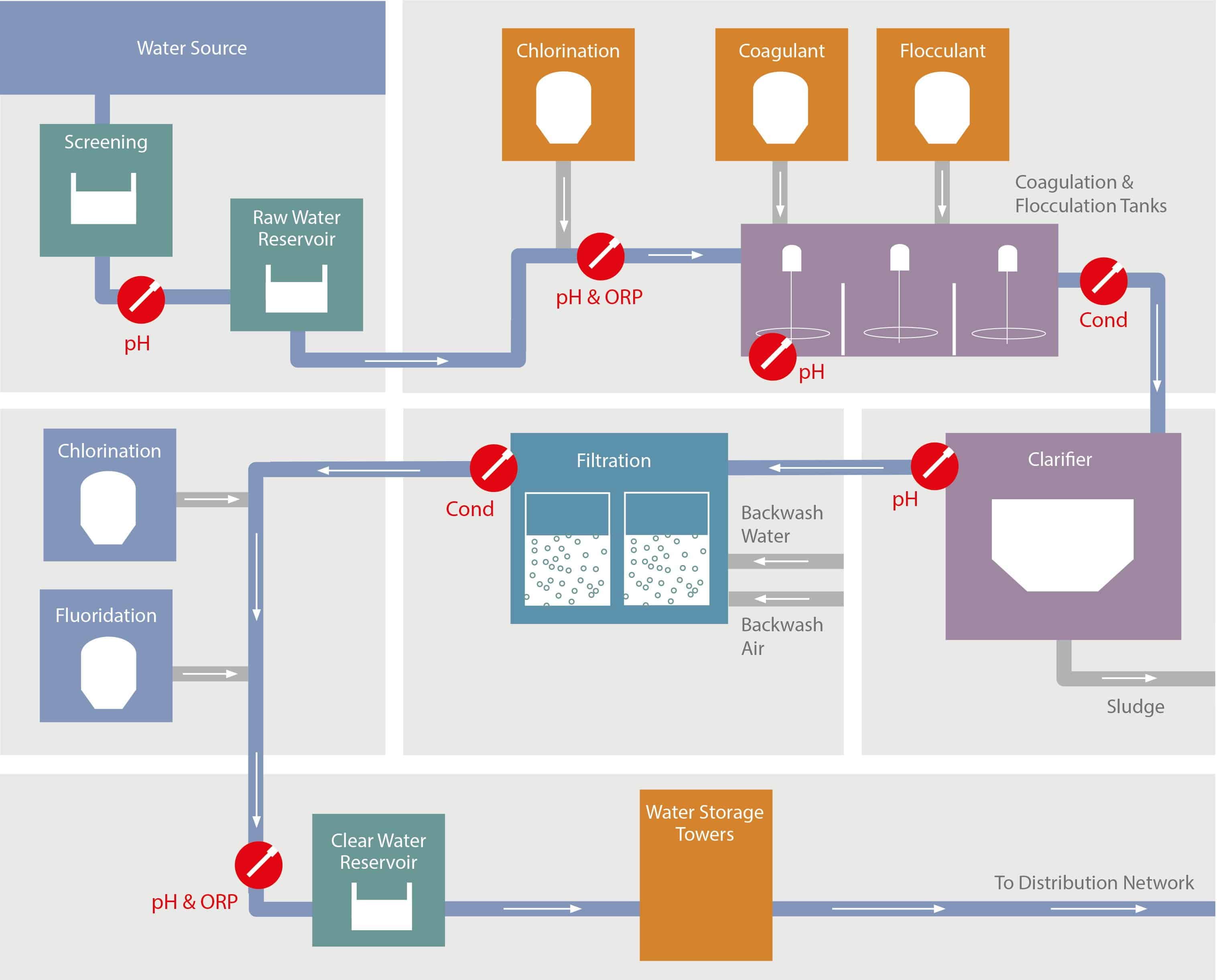

在将来自湖泊、河流或水井的原水作为饮用水送入供应管道之前,要通过各种分析和过滤方法确保其安全无害。尽管只能在连续进行的漫长分析程序中检测到某些病菌和有害物质污染,但技术人员可通过在线测量所供原水中的 pH 和氧化还原值,获得关于水质和应采取的步骤的重要信息。

采集原水值对整个饮用水处理过程起着决定性作用。采取中和极端 pH 值或氧化还原电位的措施不仅有利于人类健康,还能防止处理设备和过滤器过早磨损:酸性水不仅不健康,而且对水管也有腐蚀作用。

氧化还原电位所描述的则是水中还原物质和氧化物质的浓度比。主要包括硝酸盐、硫酸盐或锰氧化物。氧化还原电位低也意味着存在相当大的染菌风险。向水中加入氯之类的氧化性化学品,以提高氧化还原电位,从而扰乱病菌的新陈代谢。剂量基于氧化还原测量,必须通过可靠的值记录来避免剂量不足或者超剂量。

剂量不足会导致不能充分杀灭病菌。超剂量则会加速设备部件磨损,需要额外的处理步骤以有益于健康的方式减少氯浓度,而且会导致化学品消耗量过高,很不经济。

在线监测中的传感器污染:减少隔膜堵塞的风险

地下水的特点通常在于污染很少,根据地区条件而定,也可以从地表水和下水道中收集的降水获取原水。为了避免缩短使用寿命和维护间隔(这需要频繁中断过程),用于原水在线测量的 pH 和氧化还原传感器必须能耐受严重污染,即使在污染程度很高的情况下,也必须能通过合适的设计特征预防隔膜堵塞。

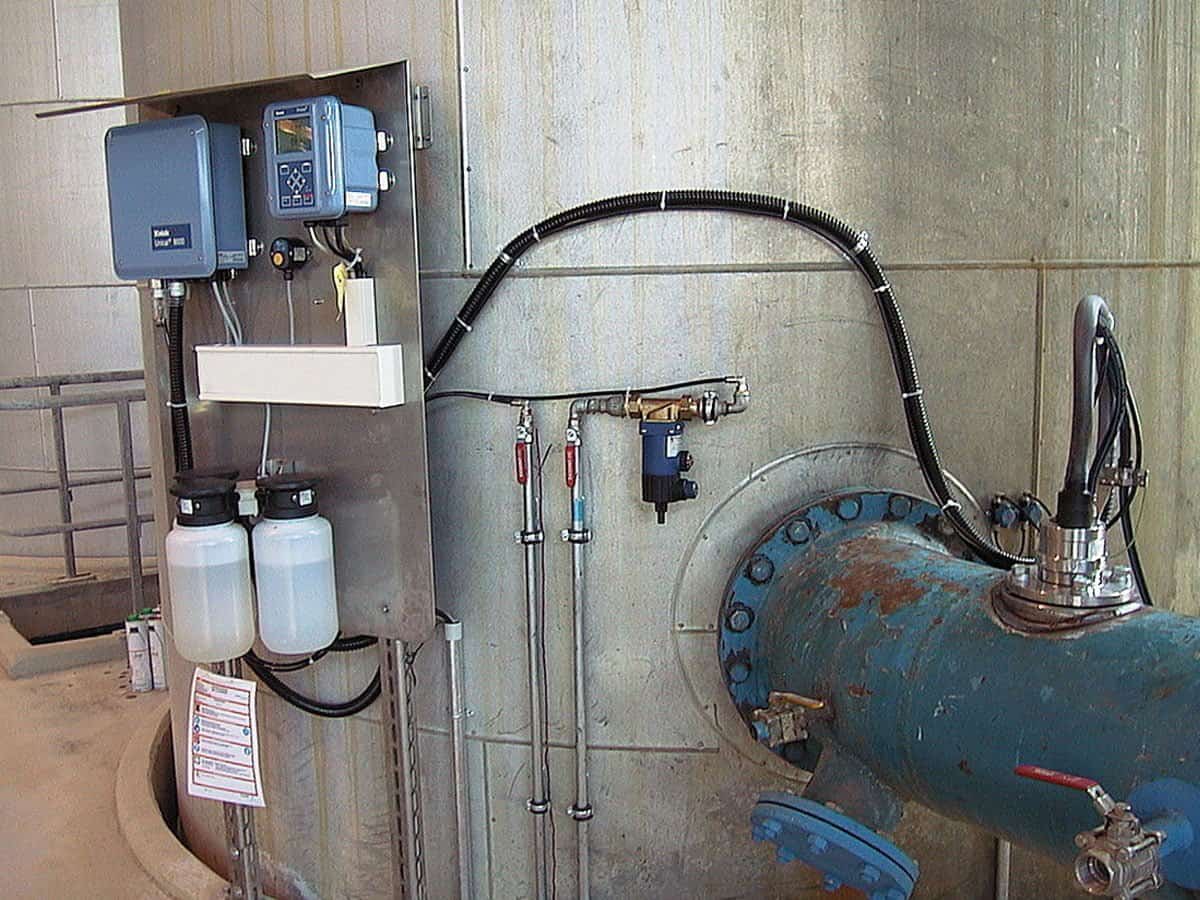

Memosens 传感器 SE554 专为在受污染的酸性或碱性介质中进行 pH 测量而开发。作为特别经济的解决方案,SE554 还有一种使用铂金电极同时进行 pH 和氧化还原测量的型号供选用。

设计有两个孔隔膜,可尽量减小堵塞或污染风险。通过较高的氯化钾含量及其在参比电极聚合物中的特殊分布,可减少隔膜上的扩散电位引起的测量干扰。

由于 SE554 传感器的稳定性和精度高,且维护工作量极少(无需补充电解质),使用该传感器有助于大幅降低总运行成本。氧化还原传感器 SE564 设计用于容易形成沉积物的严重污染介质。与 SE554 一样,SE564 的现代耐温和耐压聚合物电解质能确保长期稳定测量,无需使用传统的陶瓷隔膜。参比系统和过程介质之间通过双重孔隔膜实现接触,在含固体物质的废水中进行测量时,这种隔膜能够可靠防止堵塞。

采用 Memosens 技术,可在现场快速更换传感器,且便于查找故障

即使在恶劣的环境条件下,也能在几分钟内使用预先校准的 Memosens 替换传感器定期更换传感器。替换传感器在插接之后自动将其保存在传感器电子装置中的校准数据和传感器数据传输给变送器,从而可以继续测量,不会有明显的中断。此外,如果测量回路出现问题,Portavo 系列中的便携式工业变送器还能在现场轻松快速完成传感器诊断。简单的问题通常可以通过清洁传感器或者使用 Portavo 重新校准予以排除。这样就能在许多情况下避免预防性更换传感器以及随后在实验室中查找故障。

在潮湿区域可靠传输测量值

在使用 Memosens 传感器的情况下,由于在插拔连接中以感应方式传输传感器值和馈送电压,潮湿环境也不会对测量值传输造成任何干扰。即使用长达 100 米的传感器电缆也能干净利落地传输测量值,因为测量值是数字化的,不会像模拟信号那样有衰减。如此,便能远离测量回路将变送器安装在受保护的环境中。

投资回报

- pH 或氧化还原传感器 SE554 和 SE564 采用特殊设计,即使在严重污染的介质中也能保持超长使用寿命。

- 使用 Memosens 传感器可以显著减少维护工作量并延长更换周期,从而降低测量回路成本。

- 使用预先校准的 Memosens 传感器快速更换传感器可以缩短停机时间,避免繁琐的现场校准,从而可靠防止测量值失真和后续误差。便携式工业变送器 Portavo 908 Multi 能够轻松采集远距离测量回路的校准数据和传感器数据。