过程分析

监测制糖

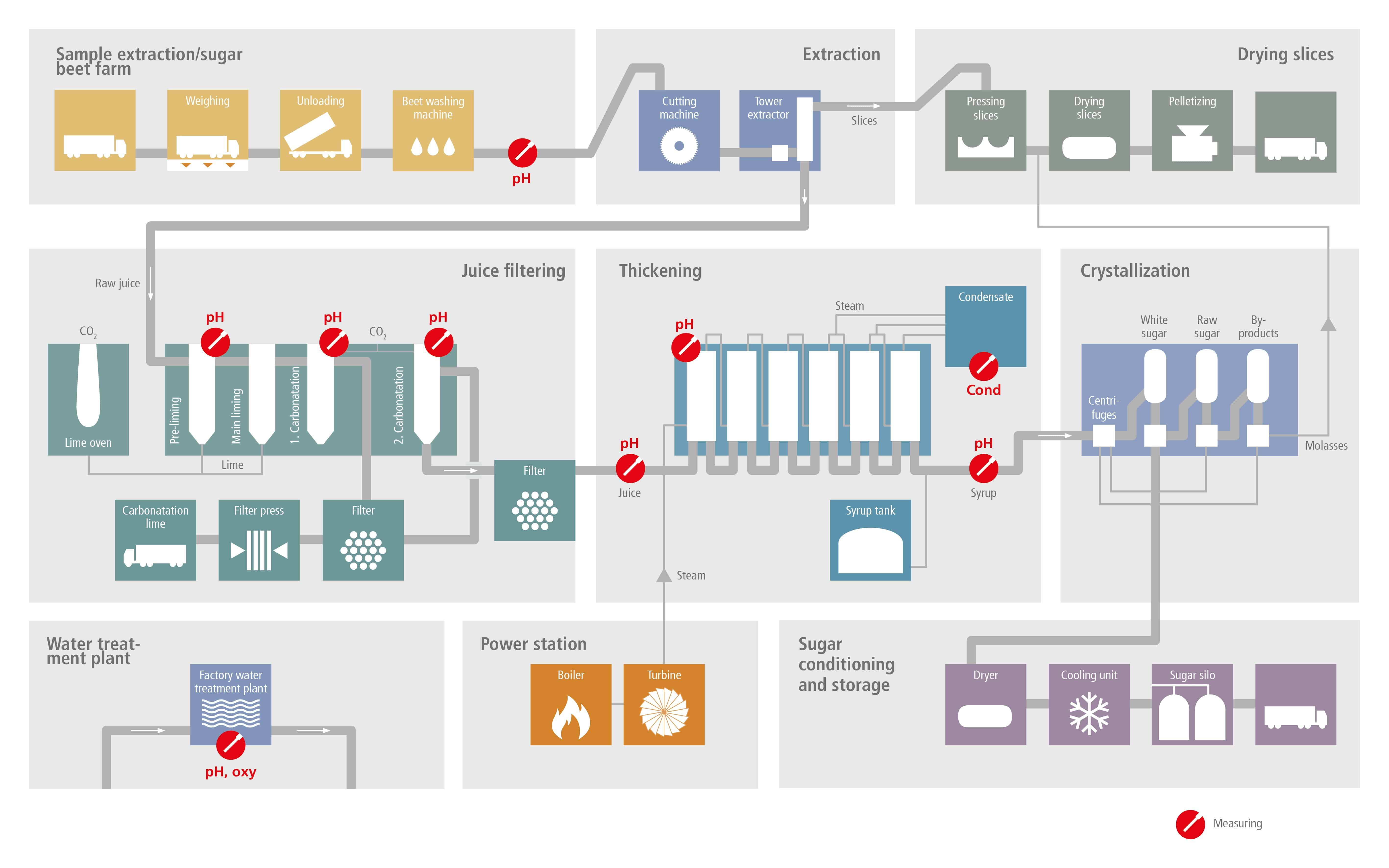

收获甜菜之后,制糖工业持续大约四个月的生产季节就开始了。首先加入石灰洗涤甜菜,再将其切成菜丝,然后在萃取塔中利用热水提取蔗糖。此时获得的原汁仍然有大量有机物和无机物杂质,在菜汁洗涤、碳酸化过程中加入石灰乳和二氧化碳使其析出并过滤出来。洗涤后的“稀汁”随后在蒸发器中经过多阶段浓缩,成为含糖量成倍增加的浓汁。以重结晶和离心方法从中产生白色结晶糖。

由于大量水垢形成、高温和频繁使用酸性清洗剂进行冲洗,pH 测量回路会遭受极高的负荷。尽管如此,仍然必须确保最高可用性,因为在生产季节不能中断这些过程。

在制糖过程中,需要为化石燃料和现场烧制石灰支出大量成本。高度可用且精确的 pH 测量可显着减少石灰消耗量,从而降低能源需求和设备污染程度。

通过提高 Memosens 测量回路的可用性,大幅节省石灰和能源

在制糖过程中,pH 传感器要满足极端要求。在甜菜洗涤过程中,加入石灰使洗涤水呈碱性,以便中和附着在甜菜上的酸性土壤,根据 pH 测量结果定量加入石灰。

鉴于潮湿肮脏的环境以及必须经常用酸清洁传感器,pH 传感器 SE555 以 Memosen 技术典型的感应方式传输测量值,能避免因触点污染、潮湿或结垢而产生的任何问题。此外,由于可以在实验室内预先校准 Memosens 传感器,无需在恶劣的环境条件下进行现场校准。

除此之外,广泛的 Memosens 诊断功能还可以记录所有保存在电极头中的传感器标准数据和运行数据:对传感器工作时长、传感器磨损、剩余寿命、最高温度、自适应校准定时器以及校准和调整数据进行监控,可显著提高可用性。预先校准的 Memosens 传感器比传统产品的使用寿命长 40%。

根据甜菜洗涤设备与主厂的距离,自动测量回路解决方案采用 Knick 极其结实耐用而且易于维护的传感器护套 Ceramat 或 SensoGate,支持各种 Memosens 传感器,有助于减少测量回路维护人员支出。电极头内的测量值数字化使之更为便捷,可在电缆长达 100 m; 的情况下传输测量值。

在碳酸化过程中,从甜菜提取的粘稠菜汁及其最初的高固体含量对测量回路的污染尤为严重。

除了这些有机杂质之外,菜汁清洗过程中形成的大量水垢和高达 95 °C 的温度也会影响测量回路。

在糖生产季节结束时,水垢厚度可达几分米。因此必须经常用酸性溶液冲洗传感器,其使用寿命会因此而缩短。SE555 是此类应用的理想解决方案,该传感器具有陶瓷隔膜和加压参比系统,能防止侵蚀性冲洗介质。

由于在生产季节期间必须每天对 pH 传感器进行多次检查和清洁,利用远程校准探头 Ceramat WA150 实现测量回路自动化,无疑是应对极端应用的最佳选择。与自动控制器 Unical 9000 配合使用,定期全自动用酸清洁和校准传感器。

过程护套 Ceramat 由近乎坚不可摧、旋转开闭的氧化铝陶瓷以及耐腐蚀、碳纤维增强、但是不活动的 PEEK 或 PVDF 塑料外壳构成。即使在磨蚀性介质中,坚硬陶瓷的平坦密封面上也不会出现磨损。

高机械强度和耐温性以及几乎普遍的耐化性,确保即使在有大量污垢的恶劣条件下也能顺利使用。为了防止与介质接触的 Ceramat 部件严重结垢,传感器护套配有气动弹性体波纹套,可定期清除凝固在传感器套管上的沉积物。

投资回报

- 高可用性 Memosens 测量回路能确保过程的连续性和质量,并能通过精确、无故障的测量显著减少资源消耗。

- 此外,Memosens 提供的预先校准功能有助于用户节约成本,因为这些传感器比传统产品的使用寿命长 40%。

- 将 Memosens 传感器与 Knick 的 Protos 工业变送器以及自动测量、清洁和校准系统 Unical 搭配使用,还可以在传统自动化解决方案因恶劣环境条件和严重污染而失效的测量回路实现自动化。

相关产品

相关工业和应用

为延长易磨损 pH 传感器的使用寿命,尤其在难以处理的介质中,Knick 推出了相应的解决方案:cCare,通过全自动清洁和校准 pH 传感器,确保测量值精确无误,同时降低维护成本和物料成本。