食品与饮料

Knick 为食品与饮料行业的公司提供可靠液体分析方面的建议和支持。为了优化这些过程,pH、氧和电导率这些最常见的参数至关重要。

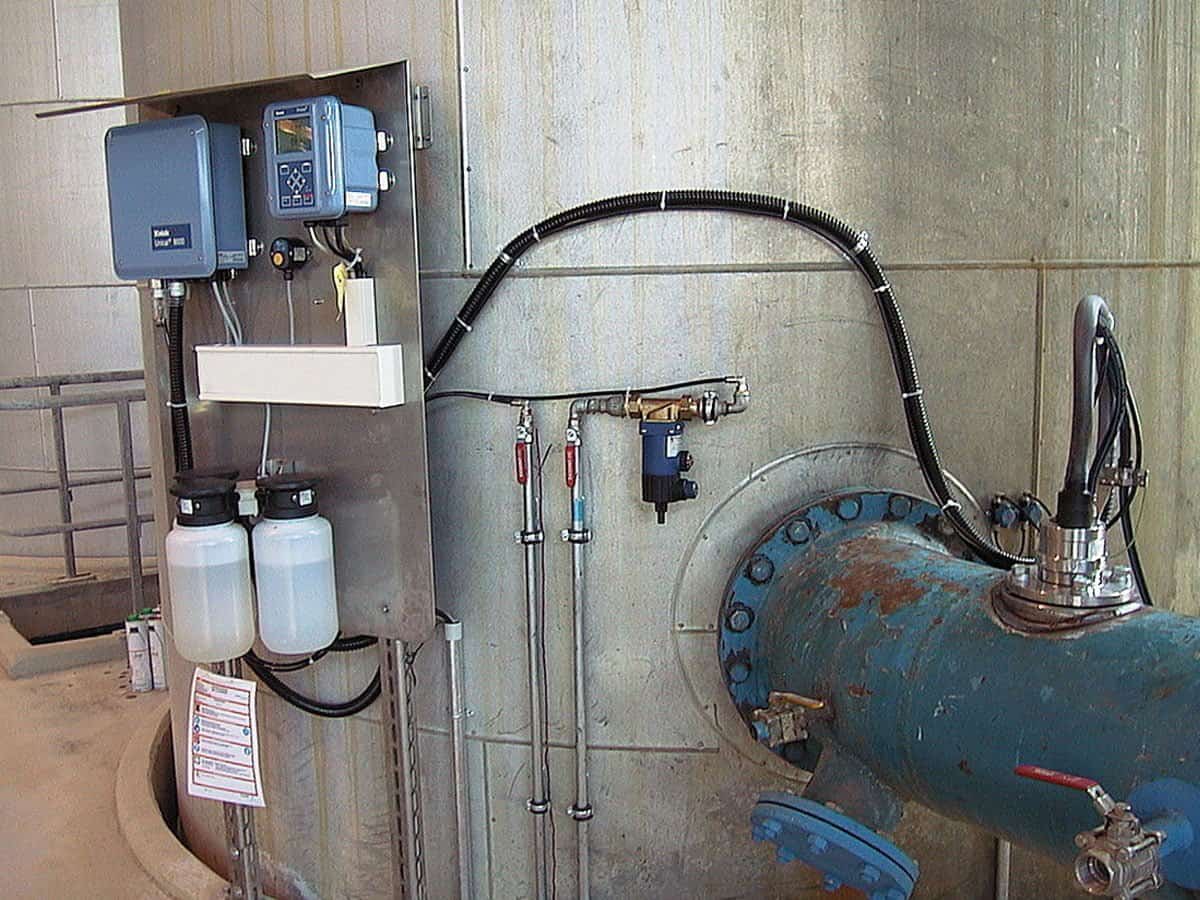

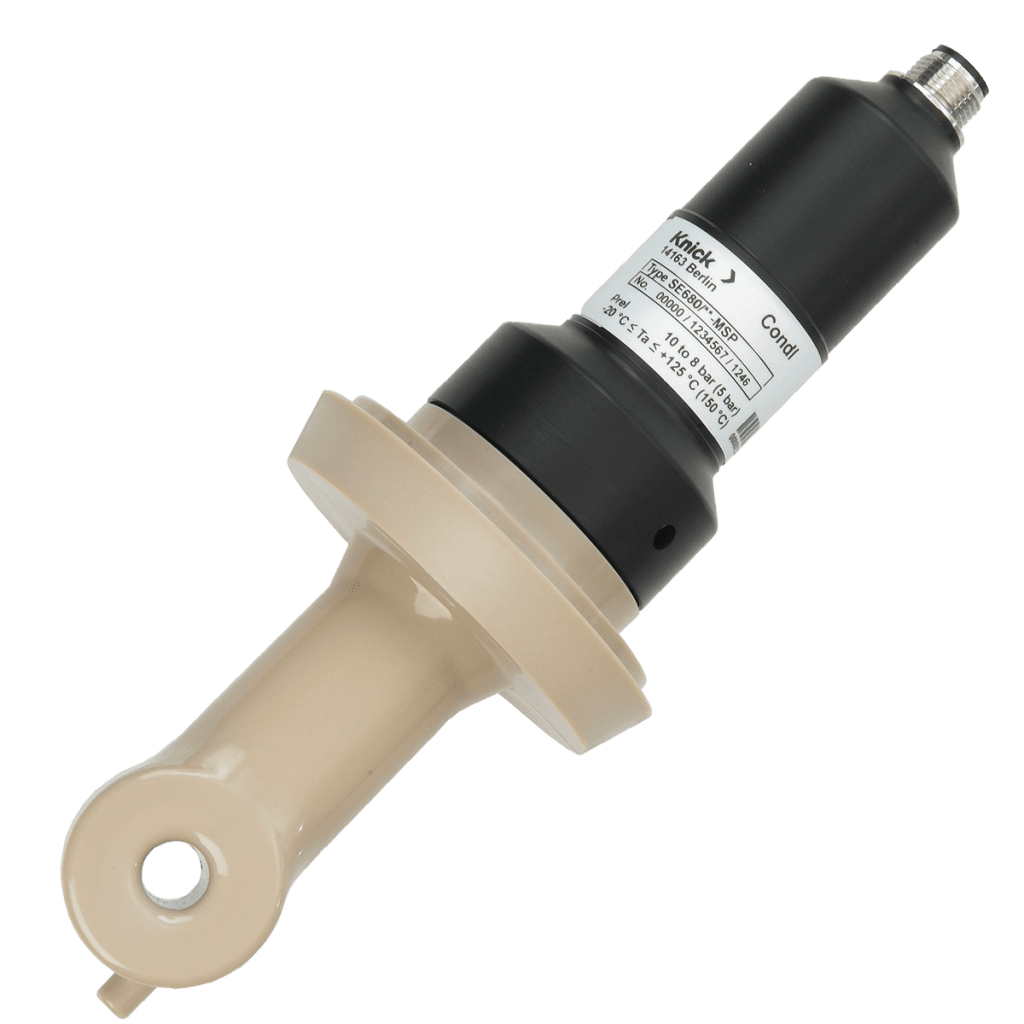

凭借广泛的传感器、工业变送器、连接件以及清洁和校准系统产品系列,Knick 为客户提供量身定制的解决方案和服务。

产品安全和质量仍然是一大挑战

食品行业的质量保证包括监测和控制各种参数,以确保产品达到所需的质量标准,可供安全食用。

除了所有卫生方面的要求(SIP 和 CIP 功能)之外,对测量技术的要求还包括防止玻璃破碎以及进行持续测量,因为许多设备生产量都很大。此外,滑脂、机油和粘性介质会使得传感器难以工作。毫无疑问,能清洁并校准 pH 传感器的全自动测量回路将是一种趋势。

啤酒厂

糖

乳品厂

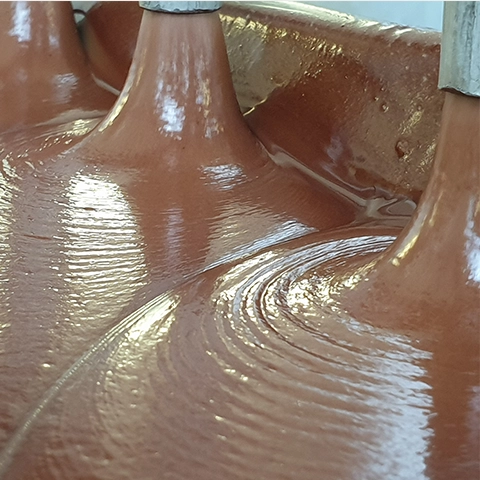

巧克力

为何选择 Knick?

从用于实验室或者现场抽样测量的便携式变送器,到具有传感器维护功能的全自动在线测量解决方案,Knick 都能一手包揽。当然是卫生级的,与过程安全隔离,无玻璃。

相关应用

您有疑问吗?我们竭诚为您服务。

联系我们