Shortcuts

Tags

Latest Posts

High-Isolation Temperature Measurement at KEMA Labs

KEMA Labs is recognized worldwide as a leader in independent testing, inspection, and certification for the energy sector. Their Chalfont, PA facility is one of the largest high-power test laboratories in North America, conducting high-voltage and high-power short-circuit testing, thermal testing, and impulse testing on a wide variety of equipment ranging from switchgear to transformers or circuit breakers.

When upgrading part of the lab’s testing systems, KEMA required a solution for temperature measurement in high-voltage environments. Reliable thermal monitoring is critical to ensure equipment safety and performance, but the challenge lies in protecting the measurement devices and personnel from the extreme electrical stresses present during testing. It was clear that no shortcuts could be taken in safety for this measurement application, especially as constant high-voltage testing would be done.

Meeting the Isolation Challenge

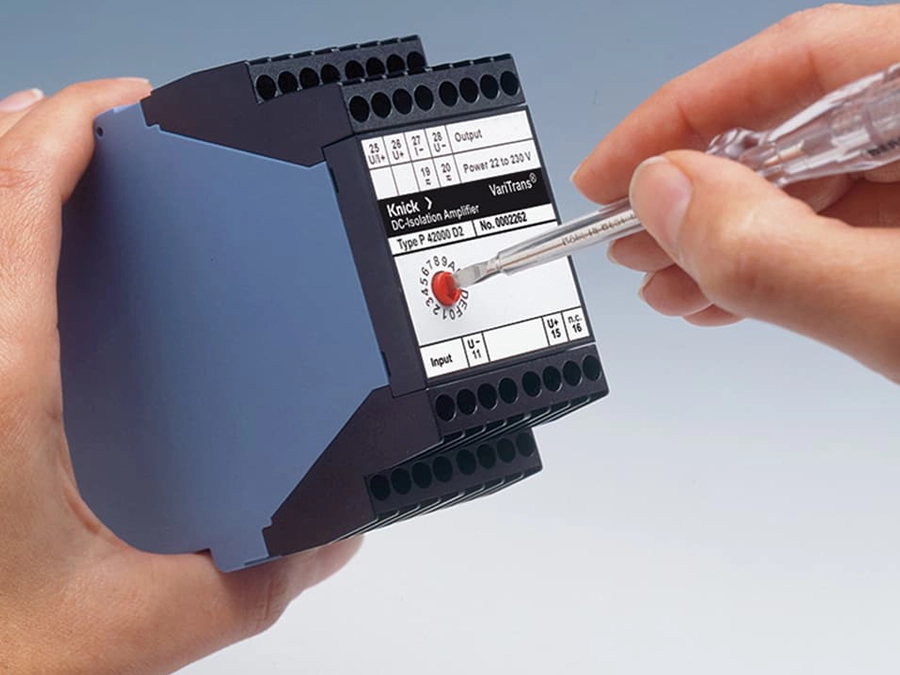

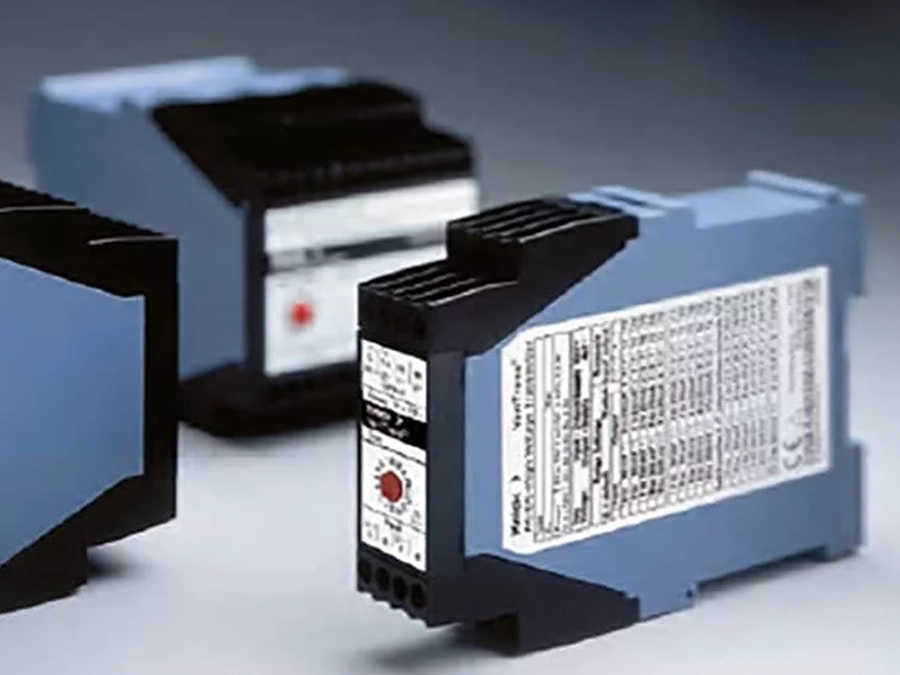

To address this need, Knick supplied 210A7 temperature transmitter units designed for 1,000 V of continuous isolation. These devices allowed KEMA to safely measure Type T thermocouples used in their thermal testing processes, ensuring accurate results while protecting downstream instrumentation from dangerous voltage levels as well as engineers from potential electrical shock while running tests.

In addition to thermocouple readings, KEMA required reliable solutions for RTDs and standard analog signal isolation. Knick supported these needs with 205A7 temperature transmitters, reading a Pt100 RTD, and P15000 signal conditioners, creating a comprehensive high-isolation measurement system tailored for a high-voltage testing environment.

Flexibility Through Custom Development

During the project, an additional requirement was identified by KEMA: the measurement of 10 Ω copper RTDs. Standard product configurations did not support this sensor type. As a result, Knick developed a custom version of the already highly configurable temperature transmitter series P32100 for RTD measurement. By programming the specific resistance characteristics of the copper RTD into the device, Knick ensured accurate measurement and provided standardized analog outputs, consistent with the other temperature transmitters used in the project. This collaboration highlights Knick’s ability to adapt and deliver customer-specific solutions that integrate seamlessly into complex customer setups.

Reliable Measurements for Demanding Applications

By combining high-isolation temperature transmitters, signal conditioners, and custom engineered devices, Knick delivered a solution that ensures both safety and precision in one of the world’s most demanding electrical testing environments. These devices now play a critical role in KEMA’s thermal testing of high-voltage equipment, supporting the lab’s mission to validate performance and safety under extreme operating conditions for years to come.

For anyone working in high-voltage test environments or applications that demand robust isolation and custom measurement solutions, Knick provides the expertise and flexibility to deliver safe and reliable results.

Latest Posts

Interface Technology

Functional Safety, Railway

Interface Technology

Data Centers, High-Voltage Transducer, USA

Interface Technology

USA, Temperature Transmitter

Process Analytics

Pharma, Protos II 4400, Launch

Company | Process Analytics

Related Posts

Feb 2026

Interface Technology

Railway, Functional Safety

SIL-compliant speed signal doubling for safety-critical applications

Nov 2025

Interface Technology

High-Voltage Transducer, USA, Data Centers

The Power Behind Data AI & Data Centers

Nov 2025

Interface Technology

USA, Temperature Transmitter

High-Isolation Temperature Measurement at KEMA Labs

Sept 2025

Interface Technology

P45000, SIL

Functionally safe measurement of high voltages in industrial applications

Sept 2025

Interface Technology

High-Voltage Transducer, Railway, USA

Upgrading Rail Infrastructure with Knick HV-Transducers and Dewesoft DAQ Systems

Jun 2025

Interface Technology

P45000, SIL, Energy

P45000 SIL 2 / SIL 3: Voltage measurements in applications with functional safety

Sept 2024

Interface Technology

Hydrogen

Stack and String Voltage Measurement in Electrolyzers and Fuel Cells

Sept 2024

Interface Technology

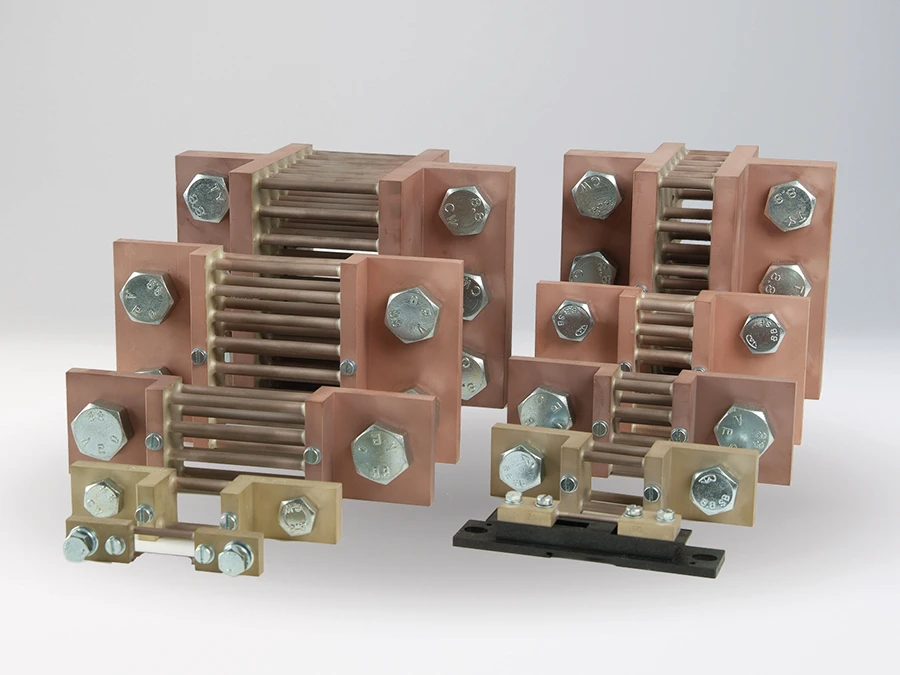

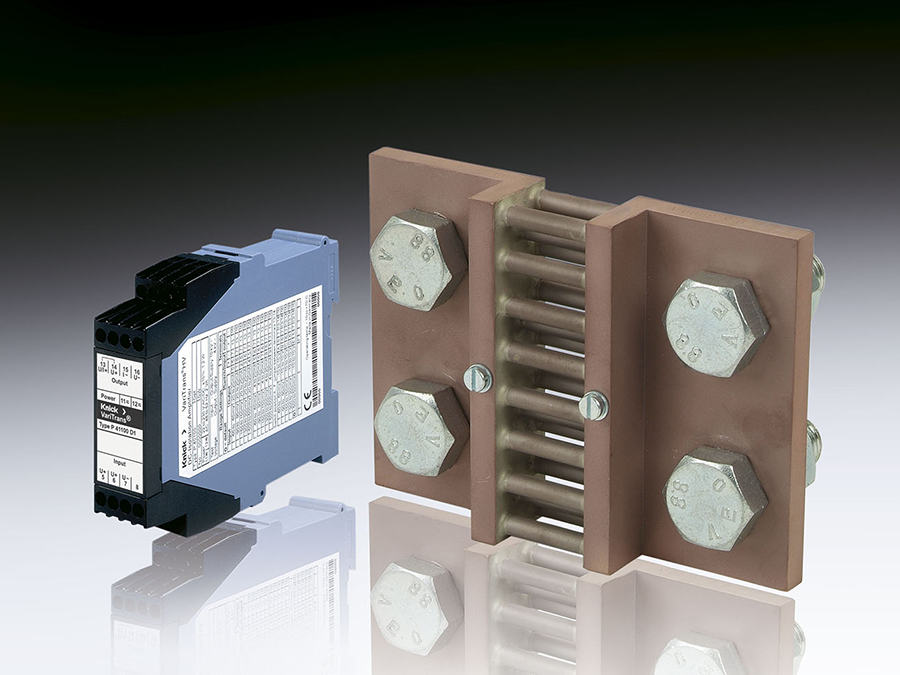

New 30 mV Shunt Resistors for Knick Transducers

Sept 2024

Interface Technology

Exhibition, InnoTrans

Innovations at InnoTrans 2024 for rolling stock and DC traction power supply

May 2022

Interface Technology

Energy

Energy storage - the handshake between renewable energy and electric vehicles

Feb 2022

Interface Technology

P52000VPD, Voltage

P52000VPD voltage presence detector reliably detects voltages up to 4200 V DC

Sept 2021

Interface Technology

USA, Exhibition

Knick Interface at Battery and Electric & Hybrid Vehicle Technology Expo

May 2021

Interface Technology

Quadruple Standard Signals in Just One Signal Conditioner

Apr 2021

Interface Technology

Hydrogen

Electrical measurement and process analytics for hydrogen production

Mar 2021

Interface Technology

High-Voltage Transducer, USA, P44000

Condition Monitoring of High-Voltage Motors

Mar 2021

Interface Technology

Pulse frequency conditioner for speed sensors

Nov 2020

Interface Technology

High-Voltage Transducer, Voltage, P42000D2

Worldwide smallest transducer up to ±2200 V

Aug 2020

Interface Technology

DC

Importance of broad-range power supplies for DC electrical measurement

Jul 2020

Interface Technology

High-Voltage Transducer, DC, P29000

Measuring Photovoltaic Degradation

Jun 2020

Interface Technology

High-Voltage Transducer, USA

Electrical Measurement Solutions: Control from 480 to 4800 Volts

Jun 2020

Interface Technology

High-Voltage Transducer

Benefits of High Voltage Transducers versus Instrument Transformers

Nov 2019

Interface Technology

DC, USA, Current

Shunt Resistor versus Hall Effect Technology

Mar 2018

Interface Technology

MTBF beyond 3000 years: A snap hook for your plant

Jan 2018

Interface Technology

UL

Knick Products Comply With UL - What Does That Mean?

Nov 2017

Interface Technology

High-Voltage Transducer, P50000

High-voltage transducer offers more safety on railway vehicles

Feb 2017

Interface Technology

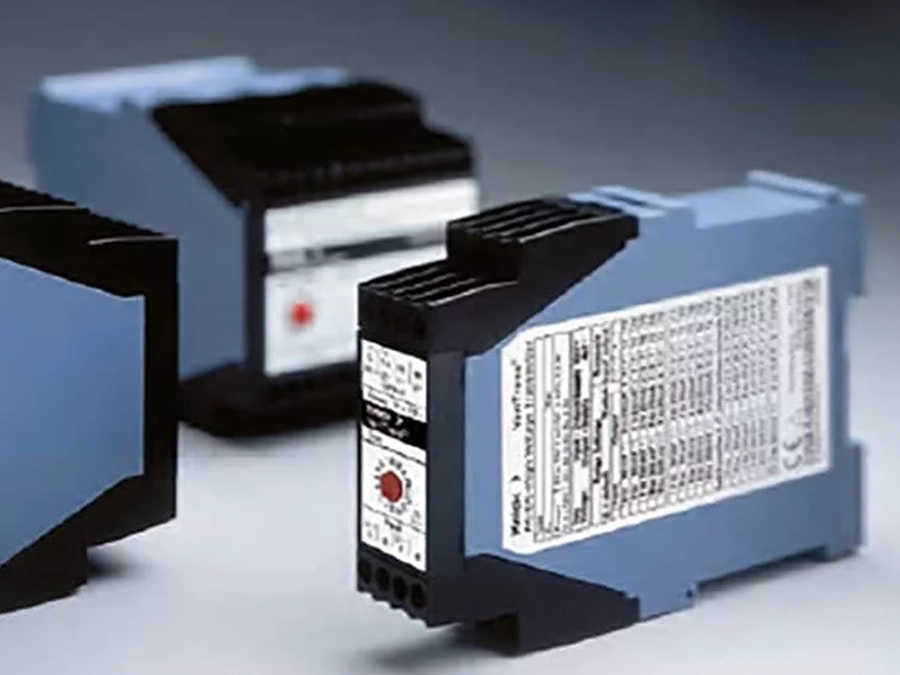

P41000TRMS

True RMS Measurement with P41000TRMS

Feb 2017

Interface Technology

SIL, P22400