BL510 标准信号隔离放大器 | 6 mm 紧凑型外壳 | 成本优化

产品编号:

BL510

Description

BL510 标准信号隔离放大器 | 6 mm 紧凑型外壳 | 成本优化

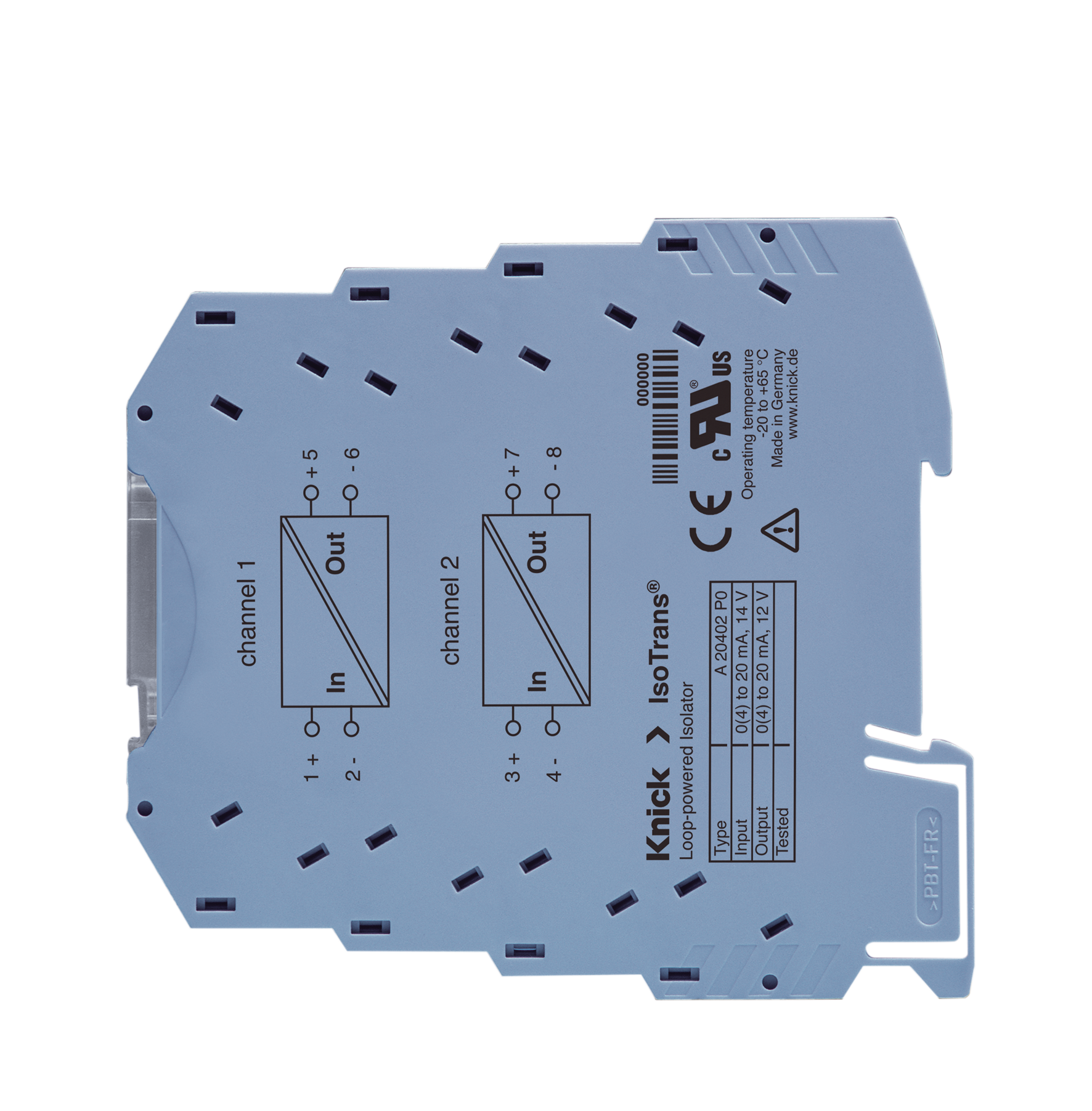

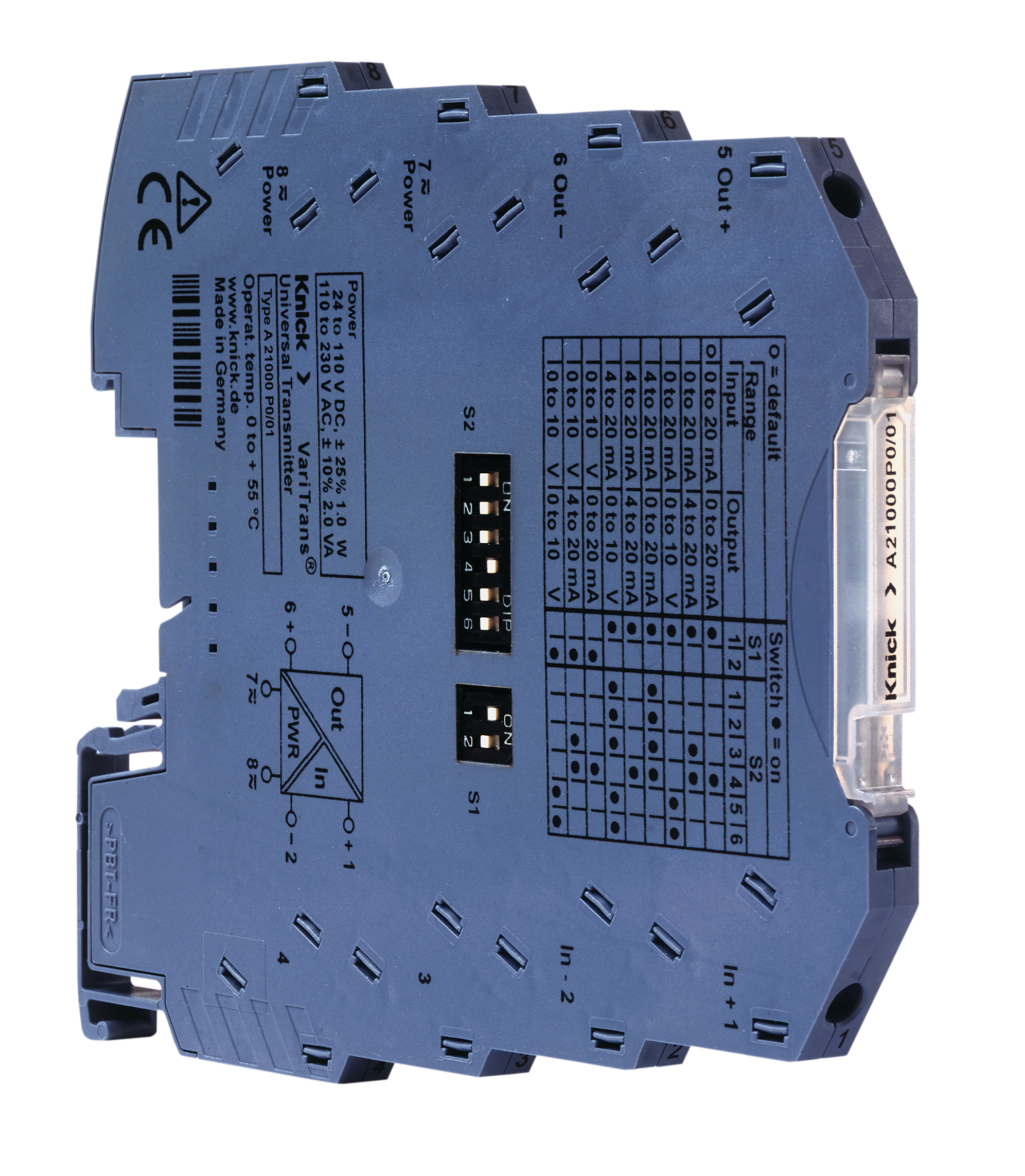

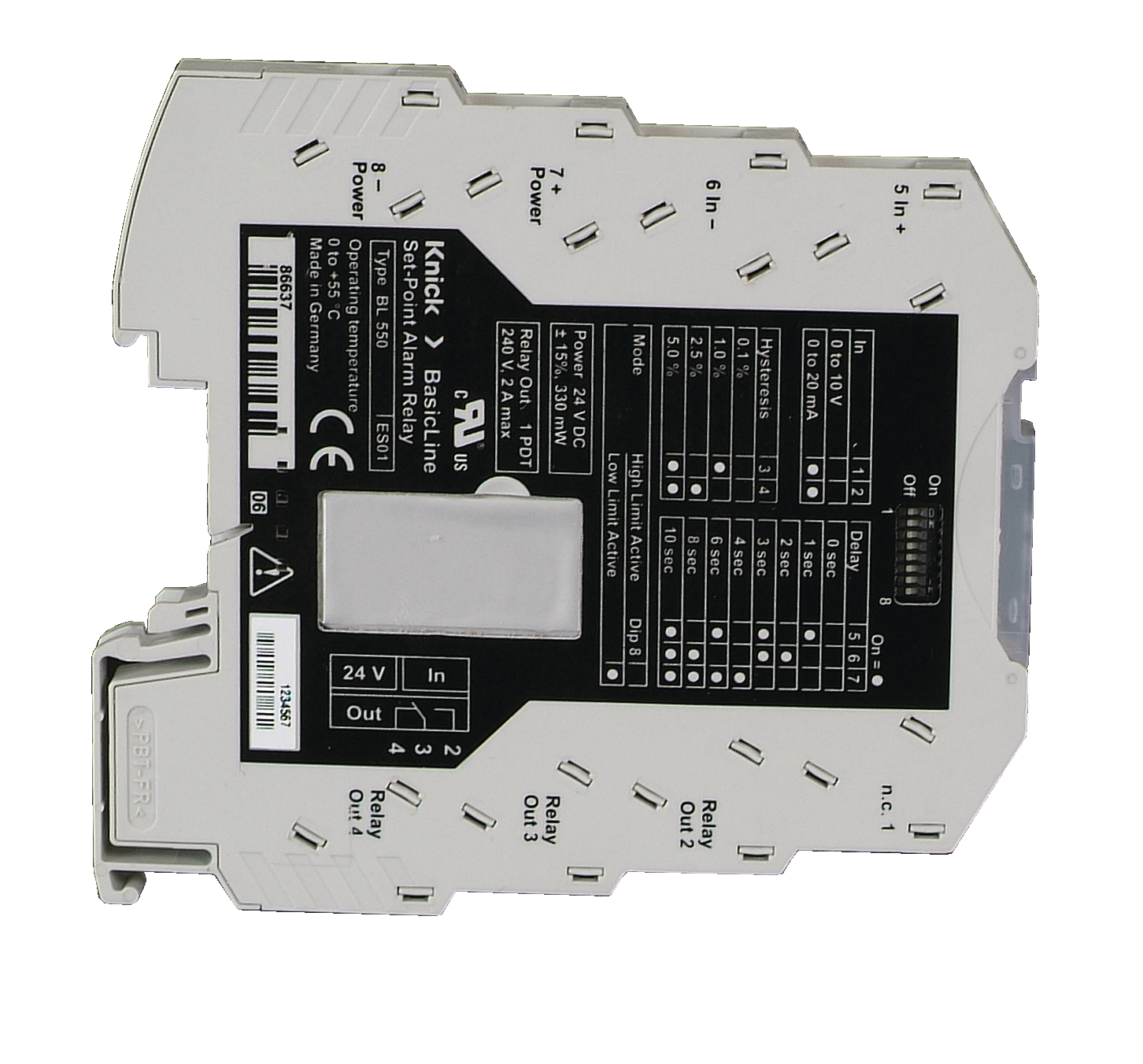

紧凑型标准信号隔离放大器,可确保在标准应用中实现充分的电气隔离和信号转换。

- 在标准应用中实现充分的电气隔离

- 将标准信号灵活转换成所需的其他标准信号

- 通过 3 端口电隔离避免测量误差

- 6 mm 外壳,空间需求极小

- 产品损耗功率极低,使用寿命长

- 经过校准的范围切换,不用繁琐的手动校准

- 通过可从外部接近的 DIP 开关轻松完成配置

- 符合 CE 标准,通过了 UL 认证

- 3 年质保

- 性价比出色

我们期待您的来信

联系我们

| 功能: | 传输/隔离/转换标准信号 |

|---|---|

| 产品类别: | 通用隔离器 / 标准信号隔离器 |