프로세스 분석

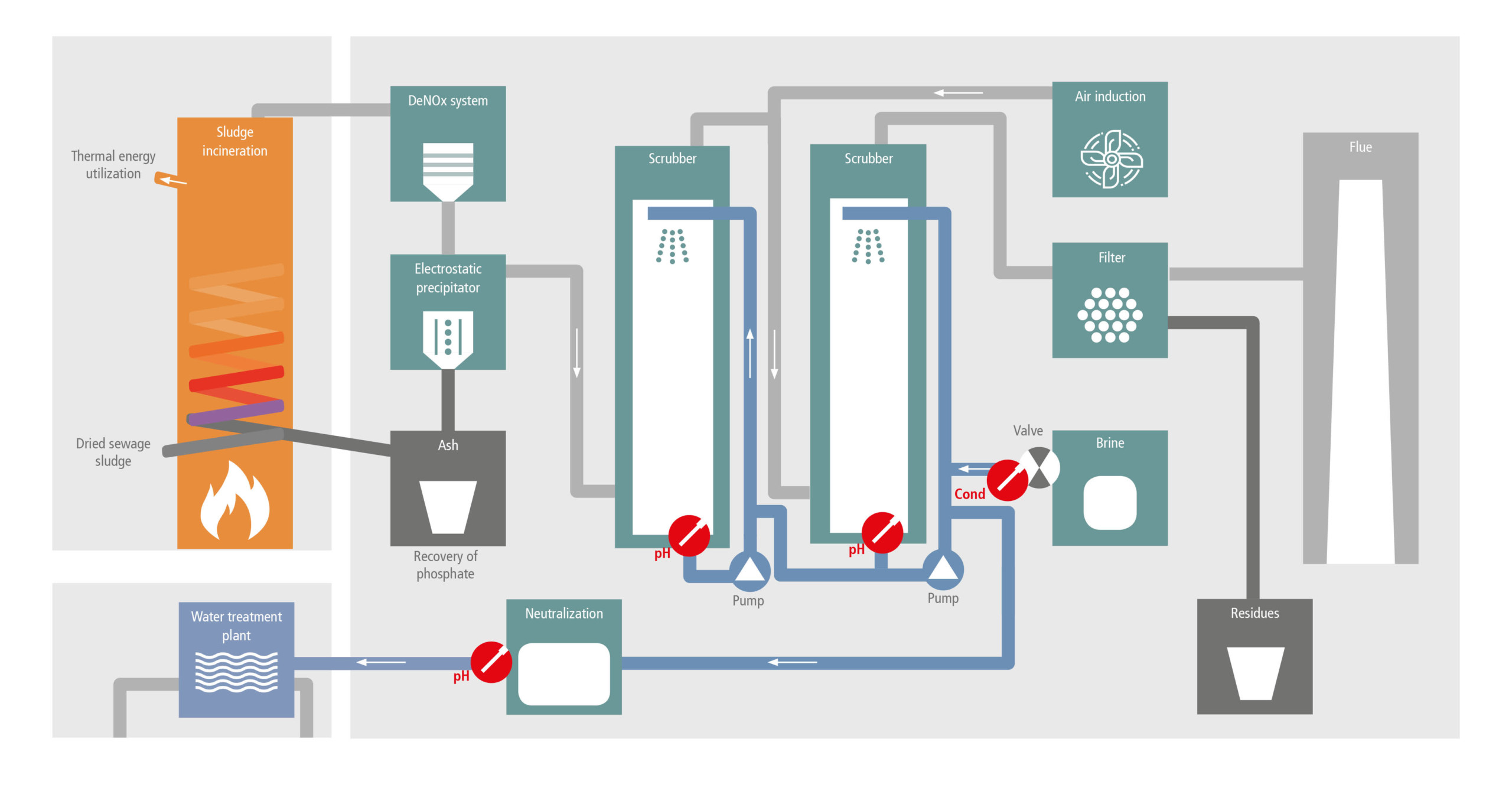

슬러지 소각 시 연도 가스 정화

생물성 폐수 정화 시설에서는 유독성 하수구 슬러지가 발생하며 이 슬러지에는 인 회수 공정을 수행해야 합니다. 소각된 하수구 슬러지의 재에서 인을 회수할 수 있습니다.

하수구 슬러지 소각 시 습식 연도 가스 정화 시설에서 결합되는 유해 가스가 발생합니다. 이때 발생하는 원수는 가성소다 수용액을 첨가하여 중화됩니다.

가성소다 수용액의 적절한 용량 공급을 위해서는 발생하는 원수에서 pH 측정을 수행하고 농도 측정을 위해 가성소다 수용액의 전도도 측정도 수행해야 합니다.

동시에 여러 측정 포인트를 모니터링할 수 있는 다채널 트랜스미터로서 공정 분석 기기 Protos는 Memosens 센서 SE656 및 SE555와 함께 안정적인 공정 제어를 보장합니다.

연도 가스 정화 후 원수 처리

현대적인 생물성 폐수 정화 시설에서는 대체로 대변을 처리하는 미생물에서 발생하는 하수구 슬러지가 남습니다. 또한 슬러지에는 중금속, 할로겐화 탄화수소 및 병원체 등의 유독성 혼합물이 포함되어 있으며 이러한 혼합물은 슬러지를 퇴비화나 비료로 농업에 사용할 수 없도록 합니다. 하수구 슬러지 재활용 개혁으로 인해 독일에서는 인 회수 공정이 의무화되었습니다. 소각된 하수구 슬러지의 재에서 인을 회수할 수 있습니다.

소각 시 얻어진 에너지는 원심분리기, 펌프 등을 위한 전기를 발전하는 데 사용할 수 있으며 폐열을 하수구 슬러지 건조에 사용할 수 있습니다. 그러나 하수구 슬러지 소각 시 환경으로 방출해서는 안되는 유해 가스가 발생합니다. 탈질화(질소 제거) 후 습식 연도 가스 정화 장치가 잔여 유해 물질을 분리합니다. 여기에 항류 원리에 따라 연도 가스를 분사된 물과 반대 방향으로 공급하며 이때 기체 형태의 유해 물질이 습식 단계에서 결합됩니다. 여기에서 발생하는 원수의 pH값은 약 2입니다.

두 번째 정화 단계에서는 대체로 유황화합물인 냄새가 심한 가스를 결합하기 위해 가성소다 수용액을 첨가합니다. 이 때 pH값은 7 미만으로 떨어져서는 안됩니다. 대부분 여러 개의 정화 장치가 공간적으로 가까운 곳에서 사용되므로 pH 모니터링을 위한 다채널 장치를 사용하면 여러 경제적, 실용적 장점이 있습니다.

Protos를 사용하여 안전한 공정 제어 및 높은 유연성

단 하나의 트랜스미터 Protos 제품군으로 여러 측정 포인트를 구현할 수 있으므로 이 공정 분석 기기는 연도 가스 정화 장치에서의 사용에서 그 적합성을 뛰어나게 입증했습니다.

간단한 경우 Protos는 릴레이 접점을 통해 가성소다 수용액 공급을 제어할 수 있습니다. 이 모듈식 트랜스미터에는 기본 사양으로 2-채널 측정에 필요한 최소 요건인 네 개의 릴레이 출력이 장착되어 있습니다.

필요 시 출력 확장 모듈을 이용하여 개수를 두 배로 늘릴 수 있습니다. Protos의 모듈식 구조는 모든 분야의 사용자에게 최대의 유연성을 제공합니다. 이전에 단일 채널이었던 측정 포인트는 예를 들어 추가 모듈을 연결하여 2채널로 작동할 수 있습니다. 추가 접점, 전류 출력 또는 제어 기능(PID)용 추가 모듈을 사용하면 언제든 간단하게 필요에 맞게 추가 장착할 수 있습니다.

Memosens 센서를 사용한 효과적인 유지·보수 방법

가성소다 수용액 농도 측정을 위해 유도식 센서 SE656를 사용하여 전도도를 측정합니다. 화학적 내성이 뛰어난 센서는 오염이 심하고 산화가 심한 매질용으로 특별히 개발되었습니다. 영구 pH값이 약 12에 달하는 정화 장치에서 알칼리화 시 pH 측정에는 수명이 약 6개월에 달하는 Memosens pH 유리 전극 SE555를 사용하는 것을 권장합니다.

실험실에서 Memosens 센서를 사전 교정할 수 있으므로 현장에서 어렵게 교정할 필요가 없습니다. 정교한 조치에도 불구하고 공정 바로 근처에 있는 직원들은 악취 오염을 견디기 어렵습니다. 따라서 건물에는 신선한 공기가 유입되고 흡입된 오염된 공기는 최종 세정식 집진 장치에서 알칼리성으로 세정됩니다.

정화 시설의 생물성 단계에 손상을 입히지 않고 세정수를 하수 설비에서 재사용하기 전에 추가 pH 측정과 함께 이루어지는 최종 중화가 필요합니다.