ANALYSE DES PROCESSUS

Systèmes de traitement de l’eau

Les centrales thermiques consomment beaucoup d’eau et requièrent un système d’évacuation viable pour les eaux usées issues des process suivants :

- Concentré d’osmose inverse (OI) et liquides de nettoyage OI

- Eaux usées issues de la régénération des échangeurs d’ions

- Eaux usées issues de la purge de déconcentration de la tour de refroidissement et du nettoyage de la chaudière

- Eaux usées issues de la désulfuration des fumées et des épurateurs par voie humide

- Déversement des bassins de cendres et des entrepôts de charbon

- Eaux usées mazoutées issues du stockage du fioul (centrales au fioul)

Points essentiels de l’application

Secteur

Traitement des eaux usées issues de différents process

Application

4 applications (1° contrôle du pH, 2° contrôle de l’oxygène dissous (DO), 3° contrôle du pH, 4° contrôle du pH et du redox) sur plusieurs postes de mesure

Paramètres de mesure

pH, conductivité et redox

Exigences principales

Forte teneur en substances étrangères, qui doivent être éliminées sous forme solide

Conditions réglementaires en vigueur pour l’élimination des eaux usées

Mesure dans les eaux usées et boues de cendres

Description de l’application

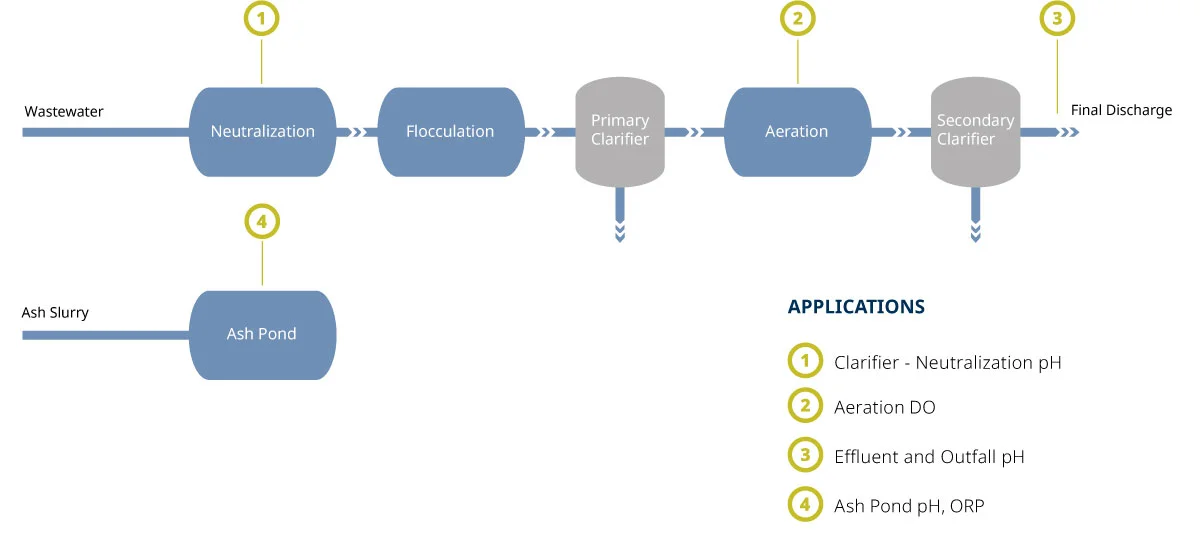

Les étapes habituelles et les postes de mesure du process de traitement préalable des eaux usées ainsi que du contrôle final de l’eau rejetée dans l’environnement sont décrits ci-dessous.

Application 1 :

les eaux usées issues de la centrale électrique sont déversées dans le bassin de décantation où elles sont neutralisées avec de la chaux. Ce process génère progressivement de grandes quantités de dépôts.

Application 2 :

après leur neutralisation, les eaux usées sont traitées avec des microorganismes dans un bassin d’activation. L’oxygène dissous y est mesuré afin de surveiller l’aération.

Application 3 :

l’eau qui quitte la station de traitement doit avoir un pH compris entre 6,5 et 7,5 pour être conforme aux exigences environnementales.

Application 4 :

le pH et le potentiel redox de l’eau du bassin de cendres doivent être conformes aux limites prescrites par les exigences environnementales.

Exigences posées à l’application

La teneur élevée en particules solides dans l’eau représente un défi pour les sondes pH, qui ont vite tendance à s’obstruer.

Des valeurs limites légales s’appliquent à l’élimination ou aux rejets des eaux usées, qui doivent être surveillés et documentés.

Pourquoi choisir Knick ?

Les eaux usées contiennent habituellement des particules en suspension – nous proposons des sondes adaptées à ces conditions exigeantes et des systèmes d’entretien de la sonde pour leur nettoyage automatique.

La technologie Memosens permet en outre de réaliser des mesures sans interférences, même dans des environnements sales et humides.

Produits correspondants

Industries et applications correspondantes

Aperçu des applications et solutions de produits spécifiques pour différents secteurs des centrales électriques.