ANALYSE DES PROCESSUS

Systèmes d’échange d’ions

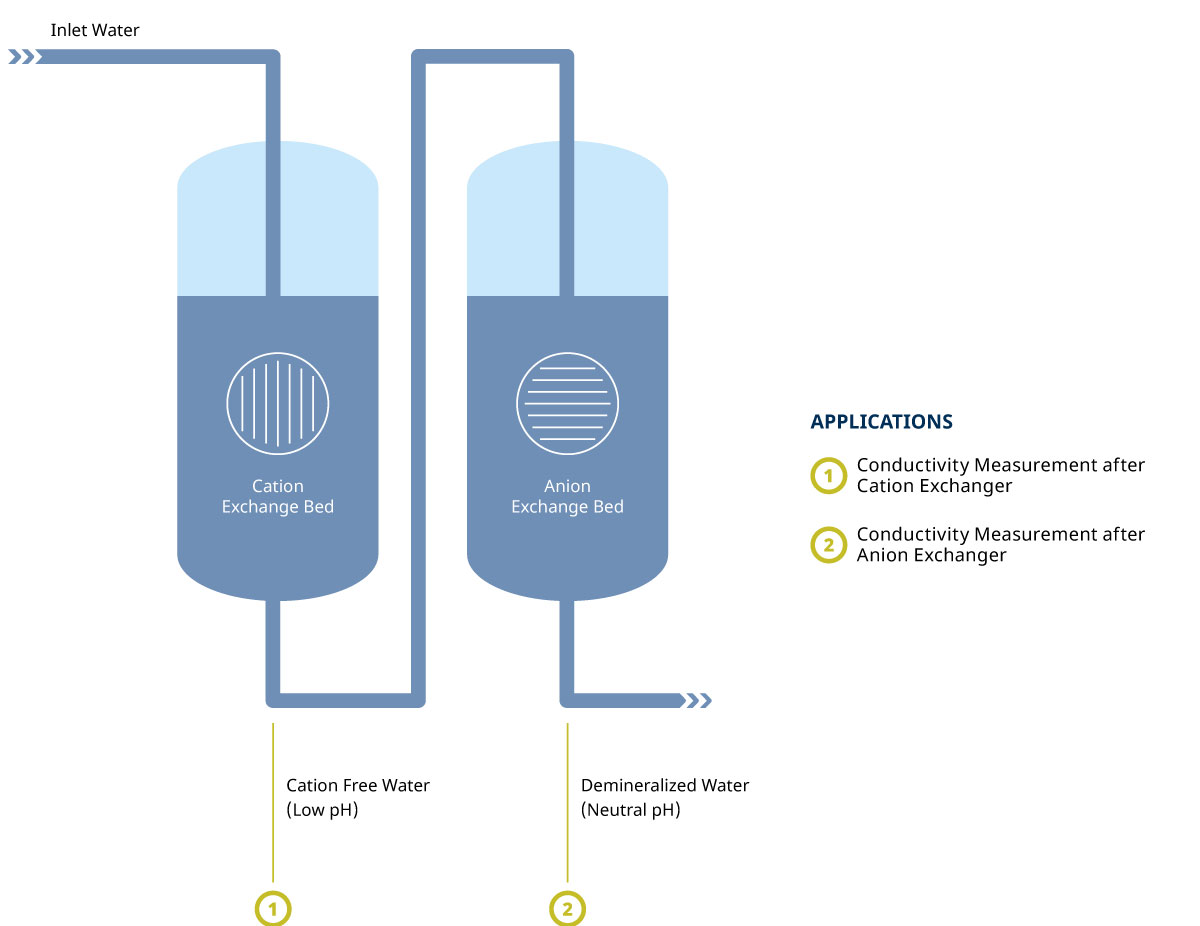

Afin de produire de l’eau d’alimentation de chaudière pure, l’utilisation d’un échangeur d’ions avec des cuves de cations et d’anions puis d’un lit mélangé pour un post-traitement appelé « polissage » est possible comme alternative au système d’osmose inverse . Des cuves sous pression en acier remplies de résines échangeuses d'ions absorbent tous les composants de sels (cations et anions) de l’eau d’alimentation. Ces résines échangeuses d’ions doivent être régénérées à l’aide d’acides et de lessives alcalines puissants.

Points essentiels de l’application

Secteur

Production d’eau d’alimentation de chaudière pure

Application

2 applications (1° mesure de la conductivité après l’échangeur de cations, 2° mesure de la conductivité après l’échangeur d’anions)

Paramètre de mesure

Conductivité

Exigences principales

Mesure dans l’eau avec un pH faible et neutre

Mesure dans l’eau déminéralisée, sans cations

Description de l’application

La conductivité et la conductivité cationique doivent être mesurées après chaque cuve. Afin de réduire l’ensemble des coûts et de raccourcir les temps d’arrêt nécessaires à la régénération, ces mesures sont obligatoires pour que le système fonctionne efficacement.

Exigence posée à l’application

La quantité de produits chimiques utilisés et d’eaux usées produites

peut être minimisée grâce à une gestion optimisée.

Pourquoi choisir Knick ?

La sonde de conductivité SE604 de Knick recommandée pour cette application est la seule sonde avec des électrodes extérieures amovibles pour un nettoyage et une manipulation aisés. Les intégrateurs et fabricants de systèmes ainsi que les constructeurs d’installations apprécient nos solutions fiables, bien pensées et précises.

Produits correspondants

Industries et applications correspondantes

Aperçu des applications et solutions de produits pour les centrales électriques