ANALYSE DES PROCESSUS

Systèmes d’eau de refroidissement

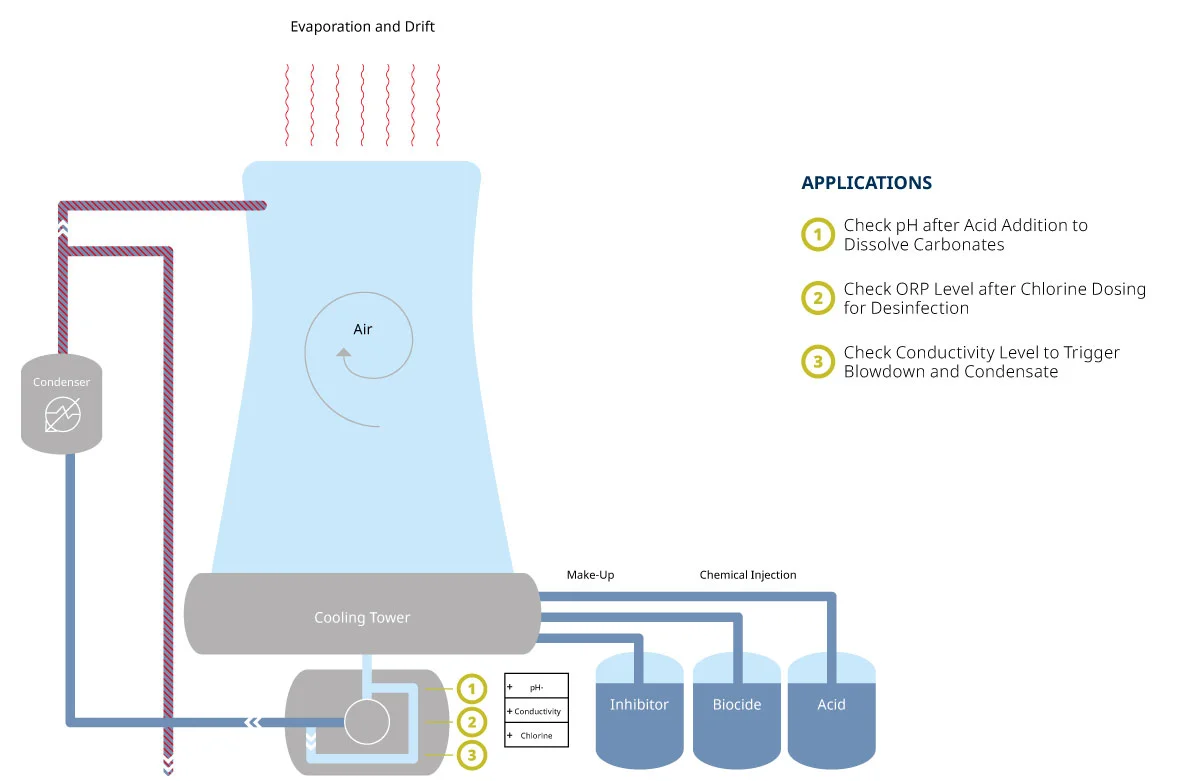

Dans une centrale thermique, un système de refroidissement efficace est nécessaire pour transformer la vapeur une fois utilisée par la turbine en condensat liquide (condenseur). Pour que le système de refroidissement puisse fonctionner de façon économique, l’eau doit subir des traitements chimiques complexes. Les tours de refroidissement occasionnent d’importants coûts d’installation et d’exploitation, et sont sujettes à une maintenance intensive afin d’éviter des temps d’arrêt onéreux de toute la centrale électrique. Les principales difficultés résident dans le dénombrement, la corrosion et la croissance biologique d’algues et de bactéries.

Points essentiels de l’application

Secteur

Centrales électriques à cycle combiné

Application

3 applications (1° contrôle de l’oxygène dissous (DO), 2° contrôle du pH et de la conductivité, 3° contrôle de la conductivité) sur plusieurs postes de mesure

Paramètres de mesure

pH, conductivité et redox

Exigences principales

Formation de tartre, corrosion et croissance biologique d’algues et de bactéries.

Acides et biocides dans le fluide.

Mesure dans l’eau de refroidissement

Description de l’application

Application 1 :

ajout d’acide pour dissoudre les carbonates avant qu’ils ne puissent bloquer le système, et ce, sous contrôle au moyen d’une mesure du pH.

Application 2 :

ajout d’un biocide (p. ex. de l’hypochlorite) pour inhiber la croissance des algues et des bactéries, et ce, sous contrôle au moyen d’une mesure du redox.

Application 3 :

il faut de temps en temps procéder à une purge de déconcentration. Remplacement de l’eau de refroidissement fortement contaminée par de l’eau propre pour diminuer la concentration en produits chimiques, et ce, sous contrôle au moyen d’une mesure de la conductivité. Voir le schéma de principe contenant des informations sur les paramètres et postes de mesure.

Grâce à la technologie Memosens inductive et sans contact de Knick, il est possible d’éviter les problèmes de maintenance liés à l'humidité et à la corrosion. Le calibrage à distance des sondes en laboratoire et le remplacement aisé des sondes sur place facilitent le bon fonctionnement du système pour les utilisateurs sans qu’ils aient à procéder à un calibrage compliqué et chronophage sur place.

Exigences posées à l’application

- Formation de tartre, corrosion et croissance biologique d’algues et de bactéries.

- Acides et biocides dans le fluide.

Pourquoi choisir Knick ?

Knick propose un système de support modulaire évolutif dans des matériaux extrêmement résistants à la corrosion et des sondes adaptées aux conditions exigeantes. Grâce aux transmetteurs industriels polyvalents Stratos Multi, différents paramètres peuvent être surveillés avec un seul appareil.

Produits correspondants

Industries et applications correspondantes

Aperçu des applications et solutions de produits spécifiques pour différents secteurs des centrales électriques.