ANALYSE DES PROCESSUS

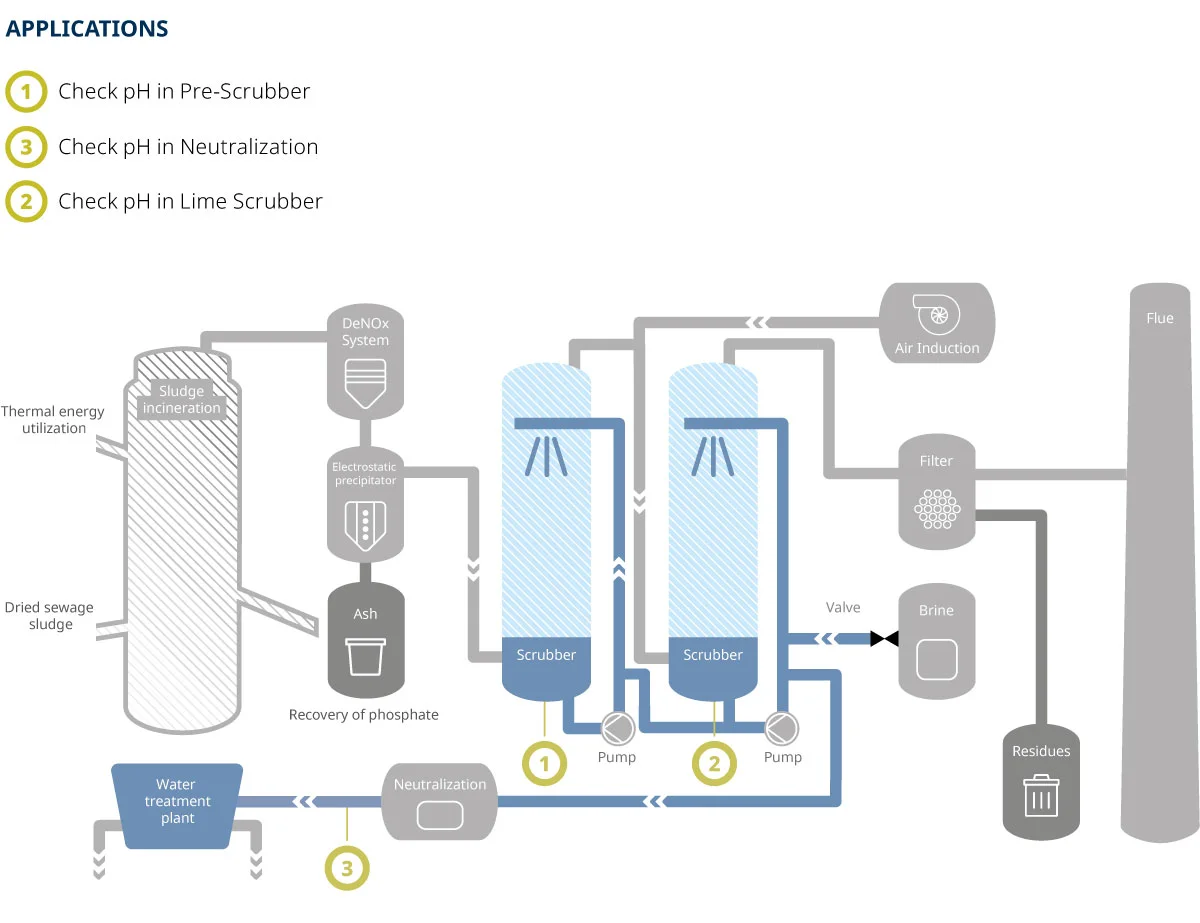

Désulfuration des fumées

Dans l’épurateur par voie humide, le gaz de SO2 corrosif est éliminé des gaz de combustion produits par les centrales à combustibles fossiles ou les usines d’incinération des déchets. Pour absorber le SO2, on utilise de la farine de calcaire, de l’oxyde de calcium ou de l’hydroxyde de calcium. Il en résulte un gypse qui peut être réutilisé par l’industrie des matériaux de construction. Une mesure précise du pH est indispensable dans ce process, afin d’éliminer complètement le SO2 et de répondre aux réglementations légales relatives à l’air propre.

Points essentiels de l’application

Secteur

Centrales électriques avec systèmes d’épuration des fumées

Application

3 applications (1° contrôle du pH dans le dispositif de prélavage, 2° neutralisation, 3° lavage à la chaux)

Paramètre de mesure

pH

Exigences principales

Les postes de mesure sont corrosifs et sujets à d’importantes incrustations.

Mesures dans des process qui forment d’épaisses couches de gypse

Description de l’application

Application 1 :

dans le dispositif de prélavage (1re étape), la fumée brûlante est refroidie par injection de lait de chaux. Le pH n’augmente que légèrement (normalement entre 1 et 2 à 80 °C). Le pH ne doit ici pas dépasser 2, car seuls le HCl/HF et les métaux lourds doivent former un précipité tandis que le SO2 sera fixé dans un second temps. Une commande précise du pH est essentielle.

Application 2 :

lors de la 2e étape réalisée dans l’épurateur principal, le pH est augmenté en ajoutant de la chaux. Le SO2 est fixé. L’ajout du lait de chaux doit être contrôlé par une mesure du pH continue. Un pH trop élevé signale que trop de chaux a été ajoutée (coûts plus élevés) et que le gypse sera donc pollué par un excès d’hydroxyde de calcium. Si le pH est trop faible, alors la fixation de SO2 est moins efficace.

Le pH optimal est compris entre 5,5 et 6,0. Des valeurs plus élevées engendrent des dépôts mous et gras de sulfite de calcium (soft plugging) et une légère baisse de l’efficacité. Des valeurs plus faibles engendrent des incrustations importantes et tenaces (formation de tartre). En général, le poste de mesure du pH est situé dans la conduite de refoulement des boues de sulfite de calcium / de gypse.

Application 3 :

l’excédent d’eau qui subsiste après la précipitation / l’épaississement du gypse doit être soumis à un procédé de neutralisation. Pour cela, on ajoute de l’acide sulfurique afin de fixer la chaux excédentaire. Ce poste de mesure est par ailleurs sujet à des incrustations et à des dépôts importants.

Ces 3 postes de mesure sont tous extrêmement importants pour des conditions de process optimales. Ces postes sont corrosifs et sujets à d’importantes incrustations et requièrent beaucoup de maintenance. Pour ces applications, Knick recommande des systèmes de nettoyage et de calibrage entièrement automatiques afin de réduire le travail manuel et d’augmenter la sécurité du process

Exigences posées à l’application

Le grand défi de cette application réside dans la formation d’épaisses couches de gypse dans les épurateurs de gaz.

Pourquoi choisir Knick ?

En raison de son étanchéité en céramique unique, Ceramat est le seul support envisageable ici. Le système d’élimination des dépôts (« Pump Sock ») pour Ceramat élimine les dépôts qui colmateraient autrement complètement le système. Le système unique d’entretien de la sonde nettoie et calibre la sonde entièrement automatiquement et réduit considérablement les besoins en maintenance.

Produits correspondants

Industries et applications correspondantes

Aperçu des applications et solutions de produits spécifiques pour différents secteurs des centrales électriques.