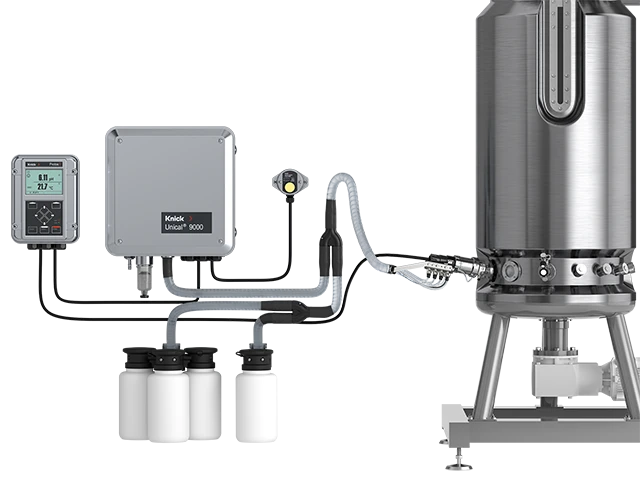

Fully automated pH measurement with the cCare sensor maintenance system

In the process industry, the pH value is the most important parameter for controlling chemical reactions and the consumption of raw materials. There is a solution from Knick for extending the service life of pH sensors, especially with aggressive viscoses and abrasive media: cCare ensures accurate measurements through fully automatic cleaning and calibration of pH sensors and reduces maintenance and material costs at the same time. As an autonomous measuring system, cCare supplies reliable values directly to the process control systems. In this way, cCare not only contributes to process optimization, product quality, and the safety of people and the environment, but also to end-to-end digitalization in the process industry.

Why cCare?

Reducing maintenance costs

In the worst case, inaccurate pH readings can cause rejects in high-throughput productions or pose a risk when dealing with hazardous substances. The regular maintenance of pH sensors is therefore essential, but at the same time labor- and material- intensive, especially in large plants or in harsh ambient conditions. In case of electrode-poisoning or junction clogging process media, cleaning is often necessary after just a few days or even hours.

Safety and Ex approval

Many measuring points are located in explosive or toxic areas where human presence is restricted or even prohibited. As the only sensor maintenance system on the market, cCare with all components is approved for use in Ex Zone 1. Additionally, the required stay in the hazardous areas is considerably reduced by the automation of maintenance. Using pre-calibrated Memosens sensors ensures the highest possible reliability regardless of environmental conditions.

A modular system for all requirements

cCare is a flexible system that can be adapted to any application. The system consists of a Unical 9000 or Uniclean 900 electro-pneumatic controller, a retractable fitting from the Ceramat or SensoGate series, and a Protos transmitter. The system is completed by media containers with integrated pneumatic metering pumps. The components are modular in design. The fittings are adaptable to any application through many materials, process customization, and immersion lengths.

Efficiency through accurate measurements and digitalization

cCare fully automates every pH measuring point and thus contributes to end-to-end digitalization from the sensor to the process control system. The system communicates with the process control system via fieldbus. Thanks to the maximum available and reliable values, the control system can react perfectly.

c for Cleaning

The retractable fitting moves the sensor into the service position and safely seals off the process even under pressure. At freely selectable intervals, the cCare system cleans and rinses the sensor in the fitting’s calibration chamber particularly thoroughly by means of a patented 360° cyclone rinsing. Depending on the requirements of the process, the cleaning and rinsing fluids can be water, chemicals to prevent heavy deposits, or other solvents.

c for Calibration

After cleaning, the sensor is calibrated at user-defined intervals by means of a one- or two-point calibration. For this purpose, the system successively pumps buffer solutions into the calibration chamber of the retractable fitting. The transmitter compares the measured values with the pH values of the buffer solutions and adjusts the deviations if necessary.

c for Conservation

Regular cleaning and calibration not only improves the quality of the measured values, but considerably extends the service life of the pH sensors. In the case of especially aggressive or abrasive media and high temperatures, cCare can also perform short-time measurements in which the sensor is only temporarily immersed in the process medium and otherwise remains cleaned in sensor-friendly electrolyte in the calibration chamber.

Automated pH measuring point

Hazardous Areas

Sanitary Areas

Seamless data acquisition to the control system

Have a question? We are here to help.

Contact Us

cCare system components at a glance

Protos

Central programming and operating unit of the system. Simple plain text operation and easy copying of settings. Expandable to fieldbus communication and operation with Memosens, digital, and analog electrodes.

Features

- High resolution graphic display

- Carbon steel or stainless steel housing

- 4 Wire, ex zone

- Full diagnostics

- Status messages according to NAMUR

Customer Benefit

- Various input and output connections for integration into process

- Flexible due to various modules for measuring and communication

Unical | Uniclean

Electropneumatic function with service-friendly concept. Can be used directly in hazardous locations. Fully automatic, modular, low-wear and low-maintenance operation.

Features

- Automatic cleaning and calibration of pH measuring point

- Timer or remote controlled

- Available in ex zone

- Easy installation and operation

Customer Benefit

- All 5 media (air, water, cleaning and calibration solutions) are connected in one tubing and by one connector plug

- Local switch for maintenance

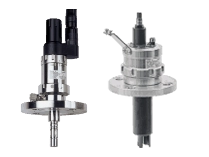

Retractable Fittings

Fittings of the Ceramat or SensoGate series can be used. Modular systems available in various designs (materials, process connections, immersion length, etc.). Adaptable to any process application.

Ceramat features a ceramic seal for long life in corrosive and abrasive suspensions, while providing low maintenance by effectively cleaning and protecting the sensor.

SensoGate is a pneumatically operated retractable fitting for various sensor types and is 100% sealed against the process medium in any position of movement. Cleaning, calibration and sensor replacement can be performed without process interruption. This fitting has the highest safety due to a special locking mechanism.

Media container with metering pumps

- Wear-free, innovative pump technology and extremely low media consumption.

- Pneumatic positive displacement pump without piston, no vibrating diaphragms or squeezed hoses.

- Pump modules are automatically recognized by the system.

- Buffer or cleaning solution containers (3.5 l) can be used as active, self-sufficient assemblies with integrated pump and can be replaced as required.

- Simple refilling of the buffer or cleaning solution, without removal of the pump, through an integrated funnel.

Service switch

Central switch for immediate retraction of the sensor into the fitting. With warning signal function and active feedback on the actual position of the sensor.

cCare for pHarma

While production in the chemical industry is mainly continuous, in BioPharma processes this is mainly done in batches. The measuring media are usually not aggressive, but the requirements for sterility and cleanability of the equipment as well as for the control of the process parameters, especially in the upstream process, are very high. There are numerous possible errors which, in the worst case, can lead to a complete batch loss.

For bioprocess applications, special modules are available in the cCare modular system for hygienic requirements. Automation standardizes the cleaning and calibration of sensors, automatically documents all process steps (audit trail) and thus eliminates operating and data transmission errors. As a result, cCare for pharma significantly reduces the risk of batch losses due to human error.