pH Measuring with Automatic Sensor Cleaning in the Filtration Line for Beer

Advantages of the Memosens technology combined with a hygienic pneumatic fitting, a controller for automatic sensor cleaning and the robustness and accuracy of our transmitters. 5 loops in the filtration line for beer, Radler and non-alcohol beer. The beer quality is validated by different parameters among them the pH value.

Keyfacts Processs/Application

Sector

Filtration lines in beer production.

Application

[Proc] What is produced: Raw material, reaction, product, waste materials, hazardous materials

[App] [location of measuring point] in [installation situation(pipe/tank/reactor) in [process step]. What are the measured values used for; how often is measured

Measured Parameter

pH

Key Requirements

[App] Medium; Measuring range; Media properties:

- Temperature range

- Pressure range

- Ex/Non-Ex

- What were the special or biggest requirements: Operating environment, legal requirements, medium, pressure, temperature

H2 [Proc] [App] Key messages, task, customer benefits

[Proc]

[App] What was the goal of the solution? Did the customer have an unsolved problem (e.g., measurement problem, safety, cost savings)? What was achieved? Optional: short (neutral) description of the customer

Why Knick ?

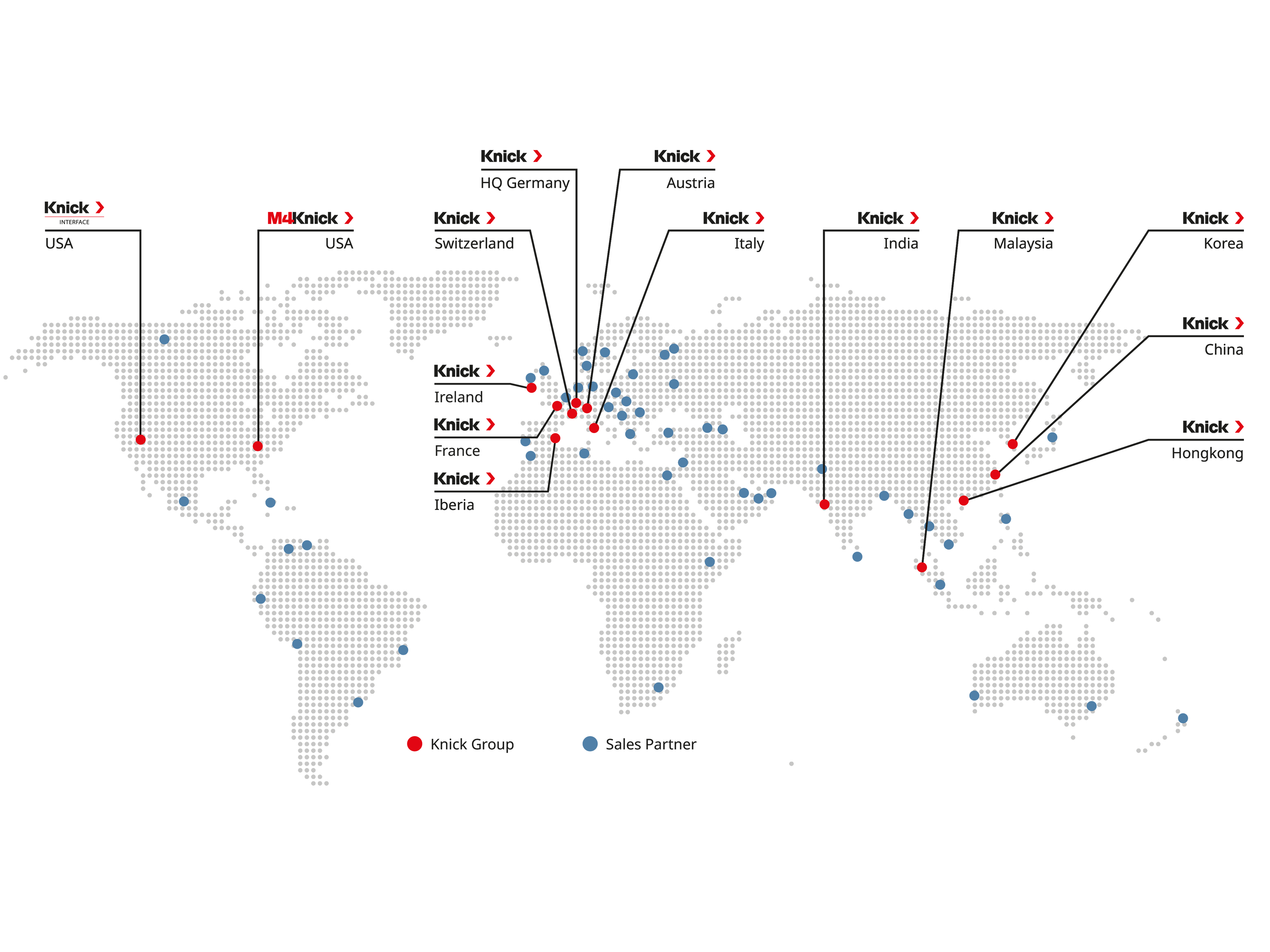

Due to many years of experience in process analysis in the energy industry and a wide range of suitable products, such as flow-through fittings, compact transmitters for DIN-Rail and multi-purpose use of the same equipment, Knick is able to adapt simple and cost-effective solutions to the requirements of measuring points.

H2 [Proc] [App] Application Description

[Proc]

[App] Detailed application description, why is measured, which customer problem is solved

H3 [App] Initial Situation

Was there a solution before, which was perhaps not good enough? Have requirements changed

H3 [App] Requirements of Application

What were the special or biggest requirements: Operating environment, legal requirements, medium, pressure, temperature, installation situation

H3 [App] Solution

Products used and why the solution was implemented in this form (transmitter, fitting, sensor, cCare)

Was a previous test necessary?

H2 [App] Video

HTML Text für Video

Matching Products

H2 [Proc] Related Industries and Applications [App] Related Industries and Processes

Overview of specific applications and product solutions in various fields of power plants.