Shortcuts

Tags

Latest Posts

How to get the sensor into the process

Sensors as the direct interface to the process must be exactly matched to the chemistry of the measured medium and to the prevailing pressure and temperature conditions. Sensors in conjunction with suitable fittings and analyzers by Knick, top performance can be achieved, even in hazardous locations.

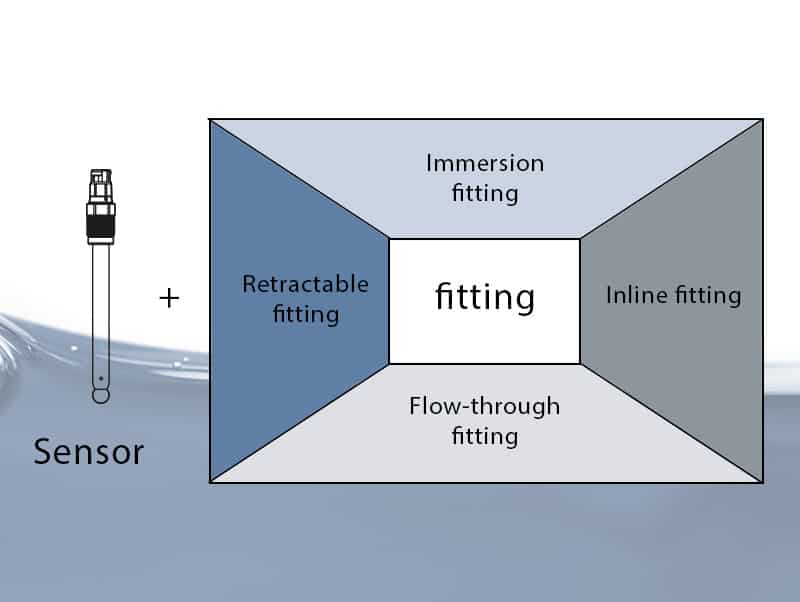

Because of the variety of production conditions, the requirements for a fitting are as diverse as they are for a sensor – pressure and temperature, the choice of materials, and above all the type and symmetry of the installation and the desired functionality, are determined by the fitting. There is a basic distinction between static fittings and retractable fittings. The static fittings are available as flow-through fittings, generally for by-pass or inline applications directly within the process flow, and as immersion fittings for measurements in basins, tanks or channels.

Retractable fittings can be used in manual or pneumatic mode to remove and service a sensor under process conditions. This can be linked with an automatic cleaning and/or calibration function.

Immersion fittings

Immersion fittings from Knick are the robust, precise and durable interface to measuring processes in tanks, basins and channels.

- adaptable to every process due to modular design

- simultaneous measurement up to three sensors

- different body materials: plastic or steel

- various process connections: pipe clamps, process flanges, and catenary suspensions

- immersion depths down to 2m

- individual sensor adaptions

- cleaning systems

The combination of an immersion fitting with a sensor lock-gate (Ceramat® WA160; see below) is unique, as shown under the retractable fittings.

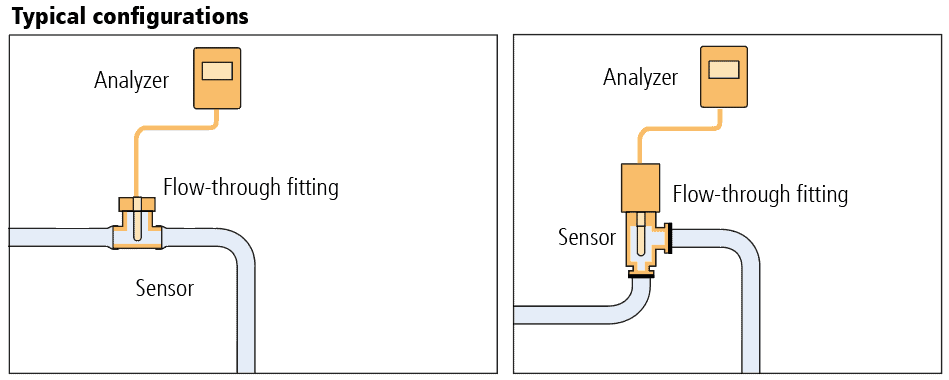

Flow-through fittings

This is most common type of fitting. Flow-through fittings from Knick are used for measuring in a bypass or in the main stream with different flow directions and generally with shut-offs on the customer side for occasional sensor maintenance. Their modular design makes them suitable for use in all conceivable processes.

- simultaneous measurement up to three sensors

- safe and easy calibration with calibration chamber

- different body material: polypropylene, PVDF, or stainless steel.

- various process connections: DN and ANSI flanges, imperial or DIN screw fittings.

- various directions of flow

- individual sensor adaptions

- cleaning system

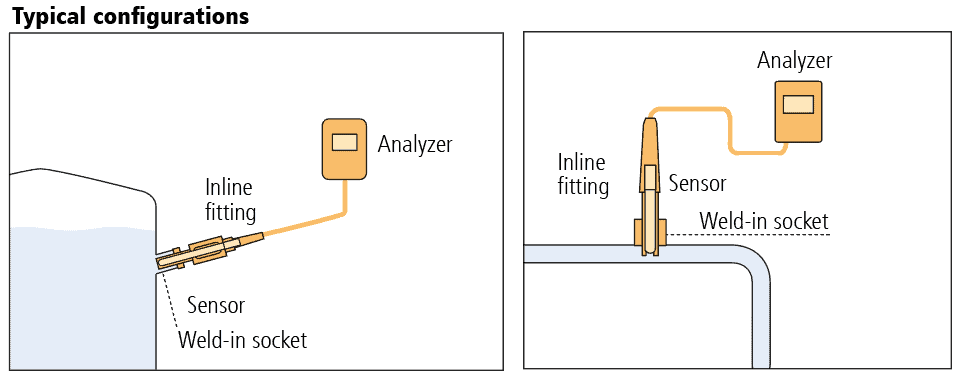

Inline fittings

Inline fittings from Knick are suitable for aggressive chemical processes as well as for processes with hygienic requirements. Expansion or replacement of components is possible at any time.

- fast and easy installations

- direct connection to pipelines or tank walls via coupling

- operation with special, pressurizable sensors possible

Retractable fittings

The successful SensoGate retractable fittings, now also available as hygienic versions, are ideally suited for manual, semi-automatic or fully automatic measurement, cleaning and calibration. The Ceramat is an automatic retractable fitting with unique ceramic sealing to the process. It is especially suited for extreme applications with difficult process media (corrosive, hot, toxic or under pressure).

- maintenance, calibration, and replacement of sensors with interrupting the process

- easy servicing of fittings due to modular design

- ceramic sealing to the process for maximum safety

- interference-free operation in fibrous and sticky processes

- immersion depths down to 2m

- low-priced version with replaceable push rod

- highly effective sensor cleaning

- seal rinsing during probe movement

- process-wetted materials: stainless steel or plastics

Direct connection of a conductivity sensor without fitting

The direct installation of certain conductivity sensors is also possible with special flanges as example on tanks or in the bypass or main stream.

Latest Posts

Process Analytics

Uniclean700, Launch

Knick GmbH Company | Interface Technology | Process Analytics

Process Analytics

Launch, Fitting, WA111

Process Analytics

Launch, Fitting, WA155

Process Analytics

Phamacy, pH, Conductivity

Related Posts

Feb 2024

Process Analytics

Uniclean700, Launch

Uniclean 700 Series - Modular control system for automated sensor cleaning

Apr 2023

Process Analytics

Launch, Fitting, WA111

Robust WA111 Retractable Fitting Made of Plastic for Highly Corrosive Operating Conditions

Apr 2023

Process Analytics

Launch, Fitting, WA155

Successful joint project : Knick developed the special Ceramat WA 155 retractable fitting for optical probes from SOPAT

Apr 2023

Process Analytics

Conductivity, Phamacy, pH

pH and conductivity measurement in vaccine production

Apr 2023

Process Analytics

Conductivity, Sensor, SE625

Sturdy 2-Electrodes Conductivity Sensor SE625 with Coaxial Electrodes made of Titanium

Jan 2023

Process Analytics

ARD75

Sensor Adapter with Lock Function Enables Safe and Thorough Cleaning

Nov 2022

Process Analytics

Protos II 4400, Module

Up to six Sensors on one Transmitter Protos II 4400 via Modul MSU4400-180

Aug 2022

Process Analytics

Exhibition, Achema

ACHEMA 2022 - Knick at the world forum for the process industry

Jun 2022

Process Analytics

pH, Sensor, SE555, ORP

Combined pH- and ORP-Sensor SE555X/*-AMSN

Apr 2022

Process Analytics

MemoTrans

Ultra Compact Transmitter for Memosens Sensors

Feb 2022

Process Analytics

Protos II 4400, Stratos Multi, Software, ProgaLog

Conveniently configure transmitters offline on a PC - ProgaLog 4000

Feb 2022

Process Analytics

Stratos Multi, Transmitter

New Stratos Multi E461N transmitter with Profinet

Jan 2022

Process Analytics

Memosens

Memosens 2.0: Evolution of digital data transfer

Nov 2021

Process Analytics

Conductivity, Sensor, Ex, SE656, SE655

SE655X Digital and SE656X Digital - Digital Conductivity Sensors with Ex Certification

Nov 2021

Process Analytics

Exhibition, Switzerland, Ilmac

ILMAC 2021 in Basel - Trade Show Review by Knick Schweiz AG

Oct 2021

Process Analytics

Stratos Multi, Transmitter, Ex

Stratos Multi E401X- Multiparameter Transmitter for Hazardous Locations

May 2021

Process Analytics

Transmitters, Stratos Multi

Stratos Multi E471 with EtherNet/IP for process optimization

May 2021

Process Analytics

Launch, Conductivity, Sensor, SE656

New SE656N digital conductivity sensor

Mar 2021

Process Analytics

Protos II 4400, Profinet

Transmitter for the process industry with PROFINET module

Jul 2020

Process Analytics

Launch, Fitting, ARD170

High-quality immersion fitting for mobile applications

Jul 2020

Process Analytics

Fitting, ARD50, ARD75

Modular immersion fitting as an electrically conductive variant

Apr 2020

Process Analytics

Launch, Transmitters, Stratos Multi

New multiparameter transmitter Stratos Multi

Feb 2018

Process Analytics

Fitting, Sensor

How to get the sensor into the process

Apr 2017

Process Analytics

MemoRail Modbus

Powerful compact analyzer boosts performance while reducing costs

Feb 2017

Process Analytics

Conductivity

High-Precision Conductivity Measurement at Extreme Temperature Differences

Nov 2016

Process Analytics

Transmitter, FF, Profibus, HART