过程分析

监测 CIP/SIP 过程

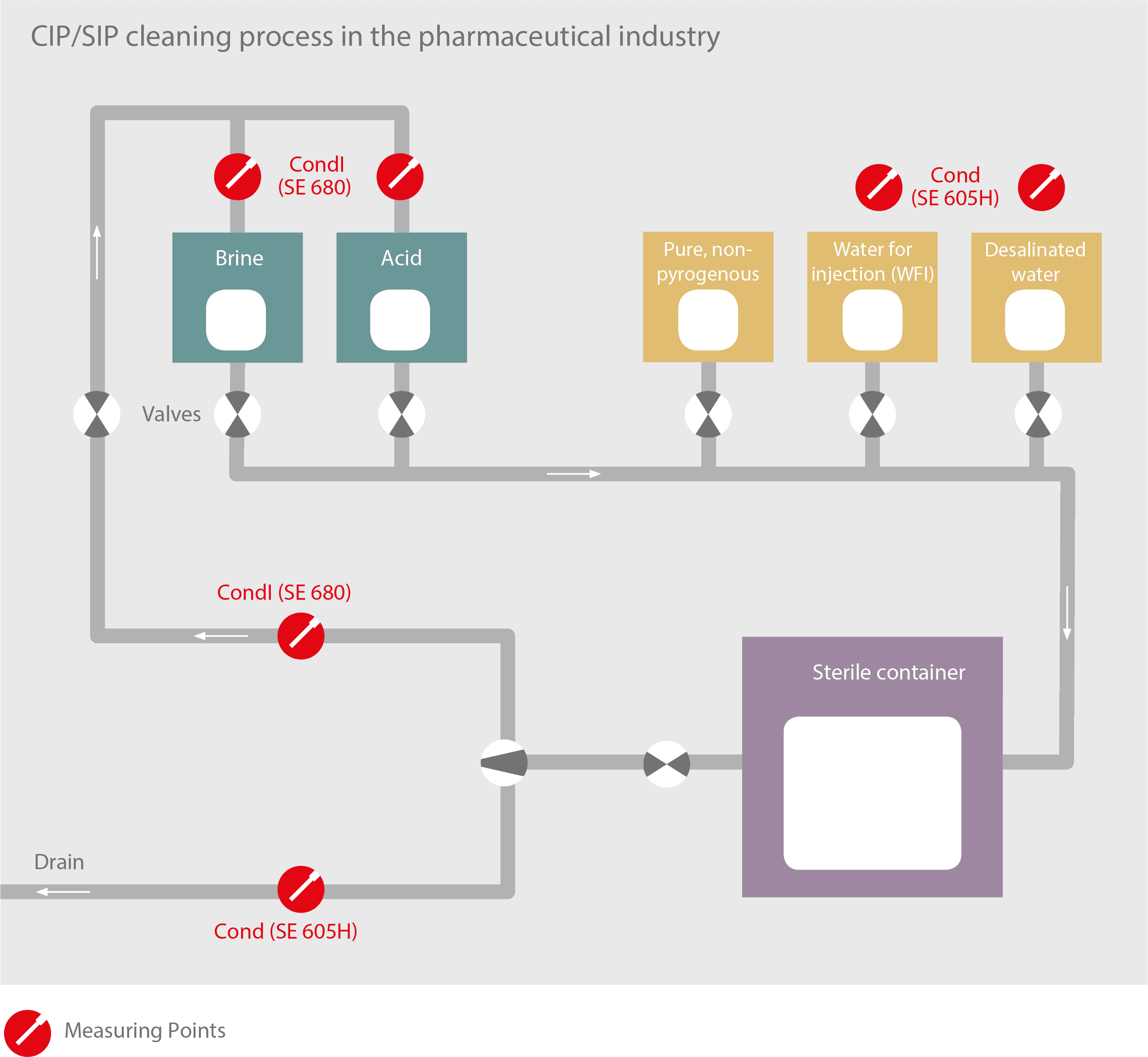

在制药、生物或者生产食品的工艺技术设备中,所有与介质接触的设备部件都必须定期清洗和灭菌。因此在“Cleaning in Place (CIP)”或“Sterilization in Place (SIP)”过程中,所有相关管路和容器都要用特定过程的碱性和酸性清洗剂进行冲洗和消毒。

在 SIP 过程中还是用过热蒸汽对过程设备进行灭菌,以实现完全灭菌。

用于监测清洗过程和冲洗水中清洗剂浓度的电导率传感器,必须能够耐受频繁的极端温度变化以及侵蚀性清洗剂。

在极端温差下可靠测量电导率

在 CIP 过程中首先用水和清洗剂进行预冲洗,去除粗大污染物,在随后的冲洗中清除残留清洗剂。然后使用酸性清洗溶液去除石灰和其他矿物沉积物,再加入消毒剂,最后用超纯水冲洗。

该清洗方法必须在每个步骤之后测量冲洗水的电导率,以获得水中剩余异物的信息。如果测量值与所要求的指标不一致,则重复相应的操作,直至达到给定值为止。

随后开始 SIP 过程。在这里不仅要对过程设备进行消毒,还要将其送入高温超纯蒸汽(> 120 °C)进行灭菌。视具体过程、批量大小和产品差异而定,有些设备需要每天清洗和灭菌数次,有些情况下甚至需要每小时清洗和灭菌一次。

所使用的电导率传感器暴露在潮湿环境中剧烈变化的温度下,在 SIP 过程中温度可能 ≥ 120 °C。电导率传感器必须符合牢固耐用、尤其是卫生设计要求。传感器配有行业专用的过程接口,并采用符合 FDA 标准的材料。

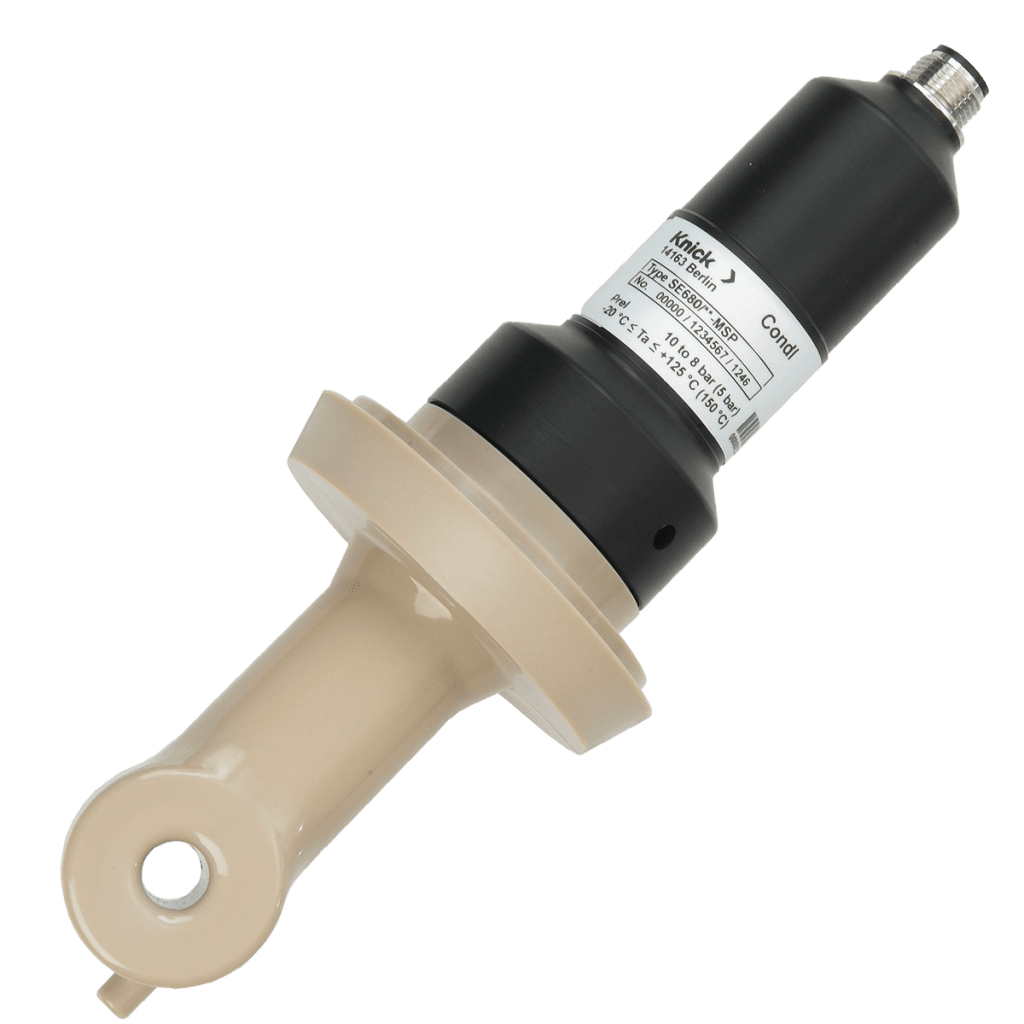

卫生型电感式电导率传感器 SE680 用于监测 CIP 冲洗回路,其特点在于 0 … 2000 mS/cm 极宽的测量范围,分辨率为 2 μS/cm。该传感器可无缝监测整个清洗过程。

由于 SE680 采用无密封、无接缝、无间隙的设计,而且表面由 FDA 批准的原生 PEEK 制成,防污性能极佳,尤其适用于制药领域。

使用 WFI(注射用水)进行最终冲洗时,超纯水的非温度补偿电导率值通常必须 < 2.7 μS/cm。较高的值表明水中仍有残留物,需要进一步冲洗。

使用专为超纯水测量范围 0.001…600 μS/cm 而设计的传导式传感器 SE605 H 来监测最终冲洗。SE605 H 采用卫生设计,有两个同轴布置的电极,材质为电解抛光不锈钢 1.4435,粗糙度深度 < 0.4 μm 或 < 0.8 μm。所有使用的材料均符合 FDA 标准。

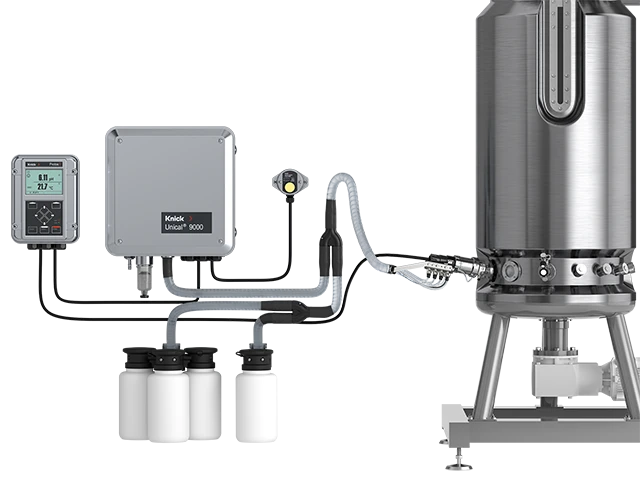

MemoRail 工业变送器可将 Memosens 传感器的测量值传输给控制系统,通过 4-20 mA 输出信号将传感器和温度值直接传输到控制系统。也可以为基于 Modbus 的控制系统选购带有相应接口的 MemoRail 版本。多参数设备 MemoRail 采用轨装式外壳,结构紧凑,节省空间,有单通道或双通道版本,广泛适用于测量 pH/氧化还原、氧和电导率的 Memosens 传感器。

投资回报

- 对于 Memosens 技术而言,重点是测量回路的成本效益。使用 Memosens 可大幅降低分析测量技术的投资成本。可以同时将两个双通道版本的 Memosens 传感器连接到多参数工业变送器 MemoRail。传感器采用纤薄紧凑的轨装式外壳,即使在空间有限的情况下,也能轻松安装到各个设备中,并通过 4-20 mA 或 Modbus 将测量信号直接传输到控制系统。

- 此外,Memosens 传感器的校准数据直接保存在电极头中,Memosens 技术还可减少测量回路的维护工作量。牢固耐用的数字电导率传感器能可靠、精确地监测过程。