프로세스 분석

양조 공정 모니터링

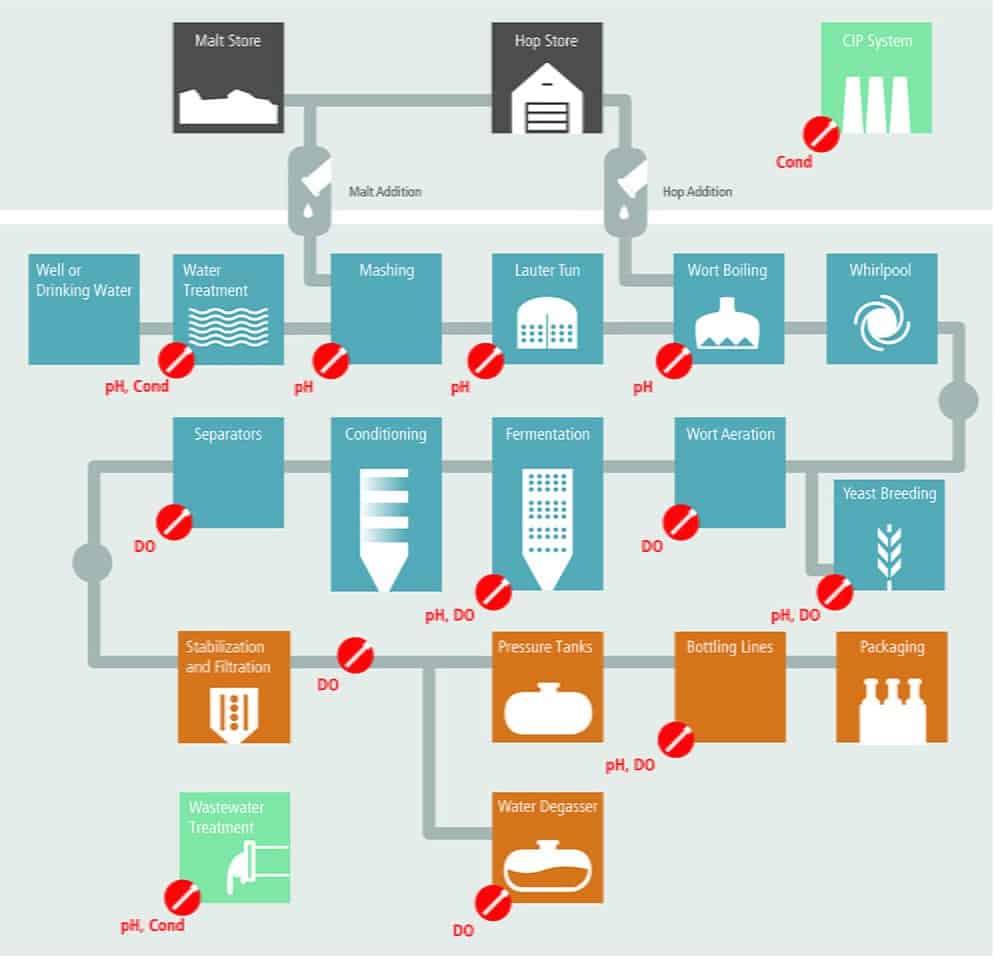

맥주의 맛과 품질은 물의 품질에 따라 크게 달라집니다. 맥주의 품질은 pH 및 전도도 측정을 통해 결정됩니다.

세계화에 직면한 양조장은 엄청난 경쟁 압박을 받고 있습니다. 시장에서 살아남기 위해서는 일관된 맥주 품질을 보장하는 것이 필수적입니다.

분석 측정 기술을 사용하면 공정 관리를 최적화하는 동시의 품질도 보장할 수 있습니다.

담금 공정에서 전분을 당분으로 변환하는 절차는 pH에 따라 크게 다릅니다.

후속 공정에서도 pH 측정은 주요한 역할을 합니다. 주조용수를 당화조에서 분쇄한 주조용 맥아와 혼합한 후 효소가 여기에 포함된 전분을 맥아당으로 변환합니다. 이 공정은 pH에 따라 크게 달라지며 5.4에서 5.6 사이의 pH 범위에서 이루어집니다. 이후 맥아즙을 끓이는 동안 홉을 첨가하여 향후 맥주의 풍미와 유통기한을 조절하고 맥주의 원액 함량을 결정하고 pH값을 낮춥니다. pH 센서SE555는 고온 증기 멸균이 가능하며 생체에 적합하므로 이러한 공정 제어용으로 설계되었습니다.

산소 측정은 안전한 공정 관리에 필수적입니다.

이후 탁한 물질(녹지 않은 호프 잔여물과 침전된 단백질)을 소용돌이 공정에서 분리하고 맥아즙에 효모와 산소를 첨가하여 실제 알코올 발효를 시작합니다. 효모에는 엄격한 규정이 적용됩니다. 최적의 품질을 보장하기 위해 효모 배양은 pH값과 용존 산소 함량 모니터링하여 이루어집니다. 산소는 발효 및 풍미 형성 과정에서 효모 활력을 결정하기 때문에 안정적인 공정 제어를 위해서는 산소 측정이 필수적입니다. 이러한 지점에서 위생적인 스테인리스강 소재의 산소 센서SE706은 신뢰할 수 있는 인라인 측정을 보장합니다.

맥주가 저장 탱크에서 그린 비어로 숙성될 때 산소 함량이 낮아 풍미가 유지됩니다. 또한 연속 산소 측정은 적시에 저장 탱크의 누출 지점을 감지하는 데 사용됩니다. 병에 담기 전에 맥주는 여과되어 가압 탱크에 보관됩니다. 맛을 보장하고 산화를 방지하기 위해서는 최대 산소 농도 한계값을 준수해야 합니다. 일부 대형 양조장에서는 맥주의 탈산수로 희석하여 정확한 알코올 함량을 조절합니다. 탈기는 용존 산소 측정을 통해 제어됩니다. 이는 병에 담는 과정에도 동일하게 적용됩니다. 이때 유통기한 및 맛과 관련한 이유로 인해 산소 농도는 일반적으로 25 ppb 이하로 유지해야 합니다.

CIP: 유도식 전도도 측정을 이용한 세척 매질의 정량 공급

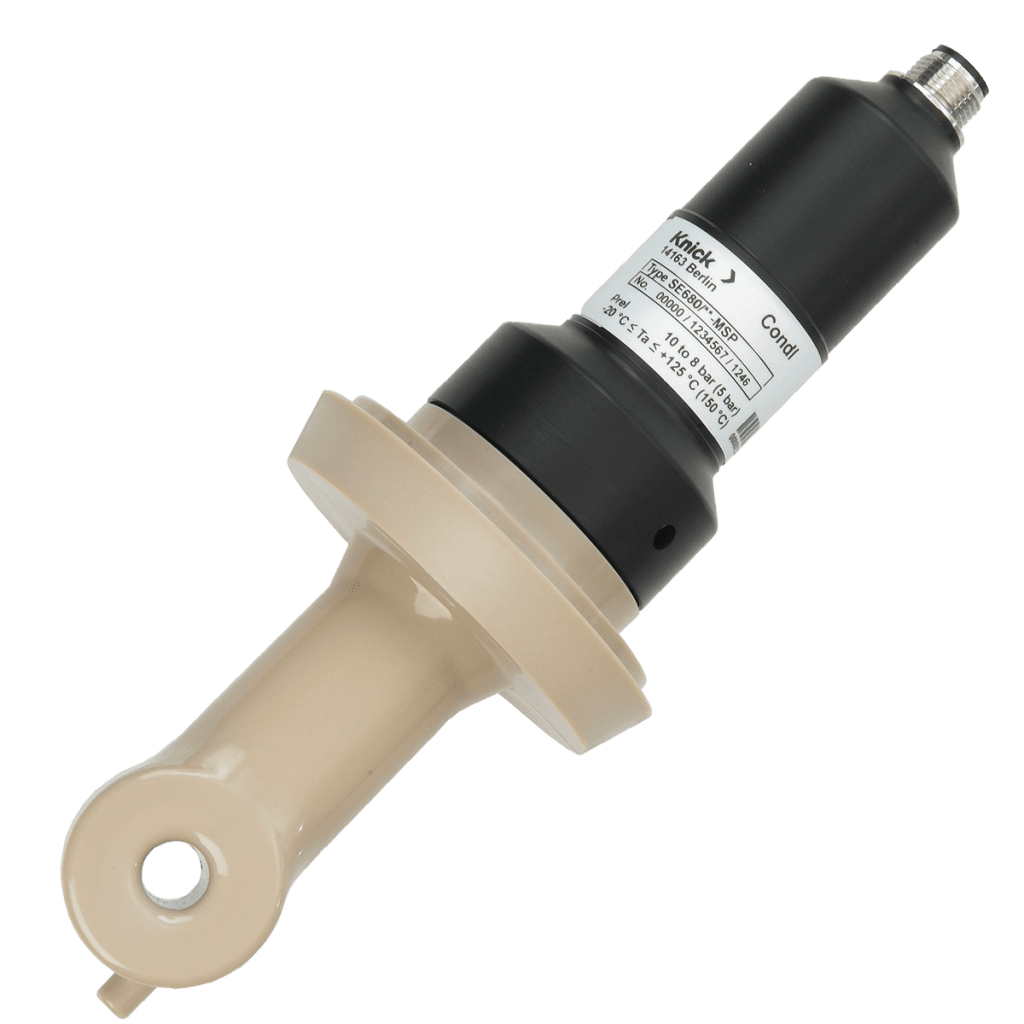

식품 제조 분야에서의 엄격한 위생 규정을 준수하기 위해 설비를 CIP 공정으로 세정해야 합니다. 이 공정에서는 65 °C의 온도에서 가성소다 수용액과 산(대체로 질산)을 번갈아 사용하여 설비를 세척합니다. CIP 매질의 농도(농도 측정)은 센서SE680을 사용하여 유도식 전도도 측정에 기반하여 제어됩니다. 세척한 공정 라인의 최종 세척 단계인 Final Rinse에서는 일반 전도도 센서SE605를 사용하여 모든 세척 매질의 완전한 제거를 확인합니다.

양조장 폐수 처리

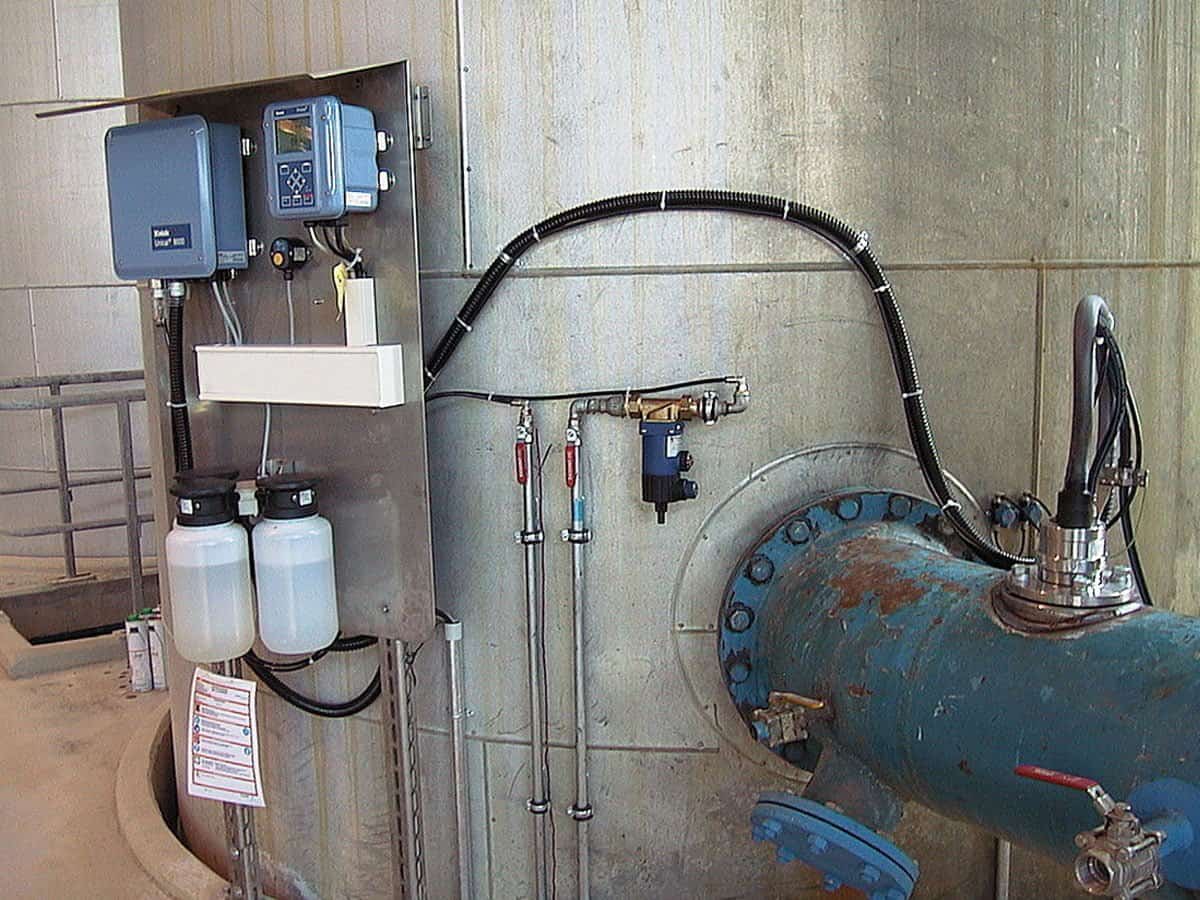

특히 pH 센서SE554, 심하게 오염된 매질에서의 유도식 전도도 측정을 위한 화학적인 내성이 강한 센서SE655 또는 장기적으로 안정적인 산소 센서SE715와 같은 Memosens 기술은 양조장 폐수 처리에도 사용됩니다. 양조장 폐수 처리 시에는 많은 양의 오염물을 고려해야 하므로 해당 측정 포인트에서 자동화된 세정 시스템을 사용하는 것이 권장됩니다.

Return on Investment

- In the moist environments of breweries and for system cleaning, the contactless inductive Memosens plug & play system guarantees unrivaled measurement reliability and quality.

- Reliably accurate measurements are essential for high product quality and safeguard the brand’s key properties from the consumer’s point of view.

- Reduced costs thanks to longer sensor service life: Memosens detects the number of CIP/SIP cycles and suggests maintenance intervals to extend sensor service life.