cCare 传感器维护系统实现全自动 pH 测量

在过程工业领域,pH 值是控制化学反应和原料消耗的最重要参数。为了延长易磨损 pH 传感器的使用寿命,尤其是在腐蚀性、高粘度和磨蚀性介质环境中,Knick 开发了一套解决方案:即 cCare,通过全自动清洁和校准 pH 传感器,确保测量值精确,同时降低维护和材料成本。作为一个自主测量回路,cCare 将可靠的数值直接返回至过程控制系统。通过这种方式,cCare 不仅能优化过程、确保产品质量及人员和环境安全,而且还有助于实现过程工业的全面数字化。

为何选择 cCare?

降低维护成本

在最坏情况下,不准确的 pH 测量值可能导致高通量生产出现不合格品,或者在与危险物质反应时引发危险。因此,定期维护 pH 传感器至关重要,但同时也要耗费人力和物力,尤其是在大型设备中或者恶劣的环境条件下。如果是会使得电极中毒或者堵塞隔膜的过程介质,通常在几天甚至几小时之后就需要进行清洁。

安全和防爆认证

许多测量回路都位于有爆炸危险或有毒物质危险的区域,这些区域限制甚至禁止人员停留。作为市场上独一无二的传感器维护系统,cCare 及其所有组件均通过了认证,可在 Ex Zone 1 等级的防爆区域中使用。此外,自动化维护还能显著缩短在危险区域必要的停留时间。无论在哪种环境条件下,使用预先校准的 Memosens 传感器都能确保极高的可靠性。

一个模块化系统,满足所有要求

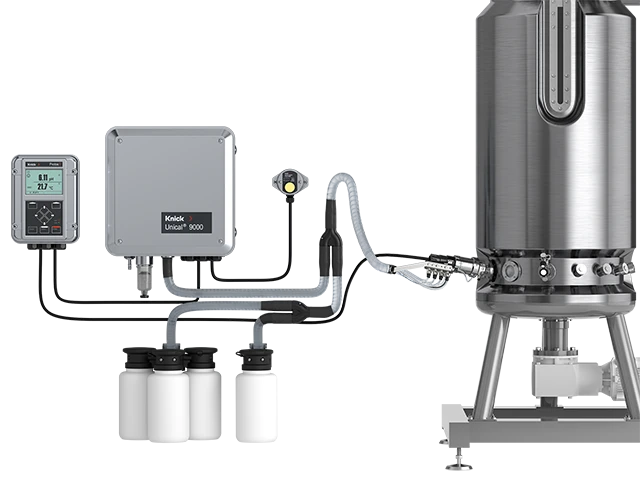

cCare 是一种灵活的系统,能够适应各类应用。系统由一个电气动控制器 Unical 9000 或者 Uniclean 900、一个 Ceramat 或者 SensoGate 系列的伸缩式连接件以及一个 Protos 变送器组成。辅以带集成式气动无磨损计量泵的介质容器。组件采用模块化设计。凭借多样的材料、过程连接及不同的浸没长度,连接件适合各类应用。

通过精确的测量值和数字化提高效率

cCare 可使得每个 pH 测量回路完全自动化,从而有助于实现从传感器直至过程控制的全面数字化。该系统通过现场总线与过程控制系统通信。得益于大量可用且可靠的测量值,控制系统能够优化所有反应过程。系统支持 NAMUR 标准 NE107,可实现“现场设备的自监控和诊断”。如此便可以提高产量,同时节省原材料并且节能。

c 表示 Cleaning

伸缩式连接件将传感器移动到连接件的维修位置,即使在压力下也能与过程安全隔开。cCare 系统按照可以自由选择的间隔时间,通过获得专利的 360° 旋风冲洗装置彻底清洁并冲洗连接件冲洗室中的传感器。视过程要求而定,可以使用水、防止严重沉积物的化学品或其他溶剂作为清洗液和冲洗液。

c 表示 Calibration

完成清洁之后,借助单点或两点校准法在用户定义的时段内校准传感器。为此,系统将缓冲溶液连续泵入伸缩式连接件的校准腔室中。变送器将测量值与缓冲溶液的 pH 值进行比较,并在必要时调整偏差。

c 表示 Conservation

定期清洁和校准不仅能改善测量值的精确度,还能显著延长 pH 传感器的使用寿命。如果是腐蚀性或者磨蚀性特别强的介质,或是在高温条件下,cCare 也可以进行短时测量,传感器此时仅暂时浸入过程介质中。而在其他时间经过清洁的传感器则留在冲洗室,并浸没在可保护传感器的电解质中。

自动化 pH 测量回路

爆炸危险区域

卫生和洁净室区域

连续采集数据并传输至控制系统

您有疑问吗?我们竭诚为您服务。

联系我们

cCare - 所有组件一览

Protos 变送器

系统的中央编程和操作单元。方便的纯文本操作,轻松复制设置。可扩展为现场总线通信,并可搭配 Memosens 数字和模拟电极运行。

特性

- 高分辨率图形显示屏

- 碳钢或不锈钢外壳

- 4 线制,爆炸危险区

- 全面诊断

- 符合 NAMUR 标准的状态消息

客户效益

- 各种输入和输出,方便过程整合

- 有各种不同的测量和通信模块,灵活性高

Unical | Uniclean

电气动功能,采用便于维修的设计。可直接在爆炸危险区中使用。全自动,模块化,低磨损和低维护运行。

特性

- 自动清洁和校准 pH 测量回路

- 时间控制或远程控制

- 可在爆炸危险区使用

- 易于安装和操作

客户效益

- 所有 5 种介质(空气、水、清洁和校准液)都在一个管路中,并且通过连接插头连接

- 本地维护开关

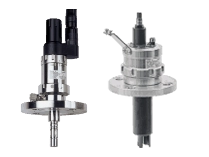

伸缩式连接件

可选择使用 Ceramat 或 SensoGate 系列的连接件。模块化系统,有各种规格(材料、过程连接、浸入长度等)可供选购。可以适配任何过程应用。

Ceramat 具有陶瓷密封件,在腐蚀性和磨蚀性悬浮液中使用寿命长,同时能有效清洁和保护传感器,维护成本低。

SensoGate 是一种气动伸缩式连接件,可用于各种类型的传感器,在任何运动位置都能对过程介质 100% 密封。可以在不中断过程的情况下清洁、校准和更换传感器。由于采用了特殊的锁定机构,该连接件安全性极高。

带计量泵的介质容器

- 无磨损的创新泵技术,介质消耗量极少

- 无活塞的气动容积泵,没有振动隔膜或者受挤压的软管

- 系统自动识别泵模块

- 缓冲液或清洁液容器 (3.5 l) 可以任意换成带内置泵的主动、独立组件

- 内置漏斗,方便补充缓冲液或清洁剂,无需拆除泵

维护开关

中央安全开关,可使传感器立即进入连接件中。带有警告功能,并能主动反馈传感器的实际位置。

用于制药的 cCare

化工行业的生产主要是连续性的,而生物制药过程则大多数分批进行。被测介质通常没有腐蚀性,但是对设备的无菌性和可清洁性、尤其对上游过程中的过程参数控制的要求非常高。出错概率极高,在最糟糕的情况下可能会导致全部批次损失。

对于生物过程应用,cCare 模块化系统中配有能满足卫生要求的特殊模块。通过自动化,传感器的清洁和校准实现标准化,系统自动记录所有过程步骤 (Audit Trail),从而排除操作错误和数据传输错误。因此用于制药的 cCare 能显著降低人为因素造成批次损失的风险。