ANALYSE DES PROCESSUS

Épuration des fumées issues de la combustion des boues d’épuration

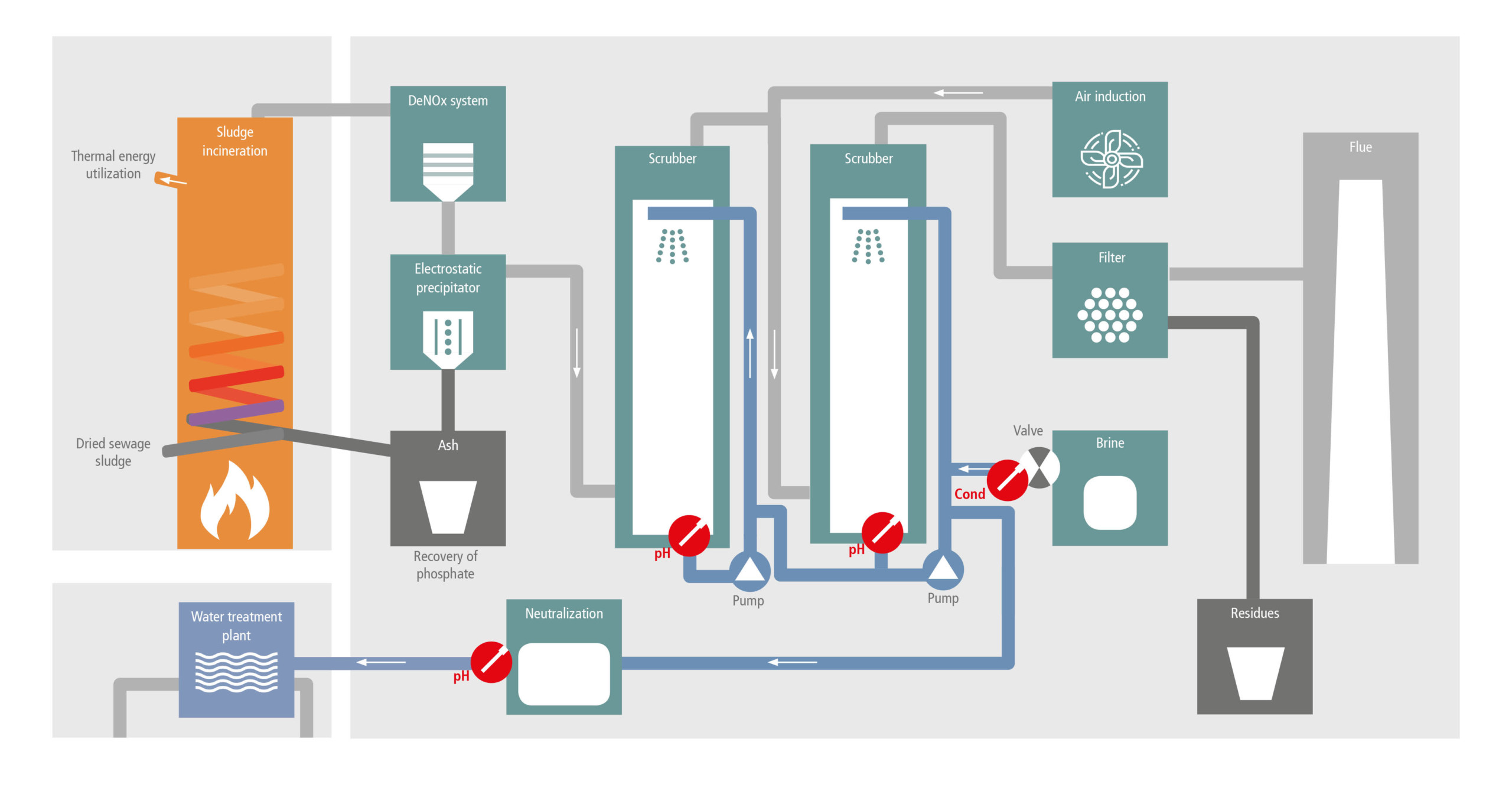

Les stations d’épuration biologique des eaux usées rejettent des boues d’épuration toxiques, qui doivent être traitées pour récupérer le phosphore. Le phosphore peut être récupéré dans les cendres des boues d’épuration incinérées.

La combustion des boues d’épuration dégage des gaz nocifs, qui sont captés lors de l’épuration des fumées par voie humide. L’eau brute obtenue est neutralisée par l'ajout de lessive de soude.

Le dosage approprié de la lessive de soude repose sur les mesures du pH dans l’eau brute obtenue ainsi que sur les mesures de la conductivité de la lessive de soude pour déterminer la concentration.

En tant que transmetteur multicanal, qui peut surveiller simultanément plusieurs postes de mesure, le transmetteur industriel Protos garantit un contrôle fiable des process en combinaison avec les sondes Memosens SE656 et SE555.

Traitement de l’eau brute après l’épuration des fumées

Les stations modernes d’épuration biologique des eaux usées rejettent des boues d’épuration qui sont principalement composées de microorganismes transformant les matières fécales. Ces boues contiennent également des additifs toxiques tels que des métaux lourds, des hydrocarbures halogénés et des agents pathogènes, qui empêchent leur compostage ou leur utilisation dans l’agriculture comme engrais. Avec le nouveau règlement relatif à la valorisation des boues d’épuration, la récupération du phosphore est désormais obligatoire en Allemagne. Le phosphore peut être récupéré dans les cendres des boues d’épuration incinérées.

L’énergie produite lors de l’incinération peut être utilisée pour produire de l’électricité pour des centrifugeuses, des pompes, etc., tandis que les rejets thermiques peuvent servir à sécher les boues d’épuration. L’incinération des boues d’épuration dégage cependant des gaz polluants, qui ne doivent pas être évacués dans l’environnement. Après la réduction des émissions d’oxydes azotés, l’épuration des fumées par voie humide assure l’élimination des substances polluantes restantes. Pour cela, les fumées sont dirigées à contre-courant de l’eau pulvérisée et les substances polluantes gazeuses sont alors absorbées dans la phase aqueuse. L’eau brute qui en résulte a un pH d’environ 2.

La deuxième étape de lavage consiste à ajouter de la lessive de soude, afin de capter les gaz très odorants, qui sont souvent des composés soufrés. Le pH ne doit ici pas descendre en dessous de 7. Étant donné qu’en général plusieurs épurateurs sont utilisés à proximité, l’utilisation d’appareils multicanaux pour la surveillance du pH présente de nombreux avantages économiques et pratiques.

Contrôle des process sûr et grande flexibilité grâce à Protos

Étant donné qu’un seul transmetteur de la série Protos permet de réaliser plusieurs points de mesure, ces excellents transmetteurs industriels ont fait leurs preuves dans l’épuration des fumées.

Dans les cas simples, le dosage de la lessive de soude peut être commandé par les contacts de relais du Protos. Dans leur version de base, les transmetteurs modulaires disposent de quatre sorties de relais, c'est-à-dire du minimum nécessaire pour la mesure à 2 canaux.

Ce nombre peut être doublé avec un module d’extension de sortie si nécessaire. La structure modulaire de Protos offre une flexibilité maximale aux utilisateurs à tous les égards. Des postes de mesure qui ne présentaient autrefois qu’un canal peuvent p. ex. fonctionner en mode à deux canaux en enfichant un module supplémentaire. D’autres modules pour des contacts, des sorties de courant ou des fonctions de régulation (PID) supplémentaires permettent à tout moment de réaliser un post-équipement facile.

Possibilités de maintenance plus efficaces grâce aux sondes Memosens

Afin de déterminer la concentration de lessive de soude, la conductivité est mesurée avec la sonde inductive SE656. Cette sonde à grande résistance chimique a spécialement été développée pour les fluides très encrassés ou très oxydants. Pour la mesure du pH lors de l’alcalinisation dans l’épurateur, qui présente en permanence des pH autour de 12, il est recommandé d’utiliser des électrodes en verre Memosens SE555, qui atteignent des durées de vie d’environ 6 mois.

Grâce à la possibilité de précalibrage en laboratoire des sondes Memosens , il n’est en outre plus nécessaire de procéder à un calibrage complexe sur place. Malgré les efforts importants déployés, les odeurs qui se répandent dans l’environnement immédiat du process seraient inacceptables pour le personnel. Voilà pourquoi les bâtiments sont ventilés avec de l’air frais et l’air ambiant pollué est aspiré avant d’être soumis à un lavage alcalin dans un épurateur par voie humide.

Avant de pouvoir réutiliser l’eau de lavage dans la station d’épuration sans causer de dommages sur ses étapes biologiques, il faut procéder à une dernière neutralisation associée à d’autres mesures de pH.

Retour sur investissement

- Longues durées de vie des sondes pH Memosens

- Plusieurs postes de mesure possibles avec un seul transmetteur Protos

- Le concept modulaire unique de Protos permet à tout moment de l’adapter facilement aux exigences de mesure changeantes.

- L’automatisation complète disponible en option pour les postes de mesure difficilement accessibles permet de réduire les dépenses liées au personnel.

- Finies les commandes supplémentaires grâce à la possibilité de doser la lessive de soude avec Protos.