ANALYSE DES PROCESSUS

Épuration des eaux usées industrielles

L’épuration des eaux usées industrielles est soumise aux réglementations strictes du décret relatif aux usages et aux conditions de réutilisation des eaux usées traitées. Un traitement incorrect ou insuffisant peut, dans le pire des cas, nécessiter une mise à l’arrêt de toute l’installation jusqu’à ce que les erreurs soient éliminées.

En ce qui concerne le traitement des eaux polluées commerciales, il ne s’agit pas seulement de respecter les réglementations environnementales : les usines consommant beaucoup d’eau peuvent diminuer les coûts liés à cette matière première en traitant et en réutilisant l’eau usée.

Le traitement biologique des eaux usées dépend particulièrement des mesures précises du pH, du potentiel redox et de l’oxygène dissous, afin de garantir un métabolisme optimal des bactéries utilisées pour l’épuration.

Mesures du pH, du redox et de l’oxygène pour une épuration des eaux usées respectueuse de l’environnement

Les polluants déterminent la procédure d’épuration

Les eaux usées industrielles se distinguent de celles ménagères par leur contamination avec des substances difficilement dégradables. En fonction du secteur, elles peuvent inclure des métaux lourds, des graisses, des huiles, des substances alcalines ou, comme p. ex. dans la production de papier et de savon, des substances organiques, qui ne peuvent être neutralisées ou isolées que par des tâches complexes.

Outre des méthodes de filtration mécaniques, l’épuration des eaux a recours à des procédures thermiques et s’appuie sur des microorganismes.

Mesures du pH pour protéger les installations et les bactéries

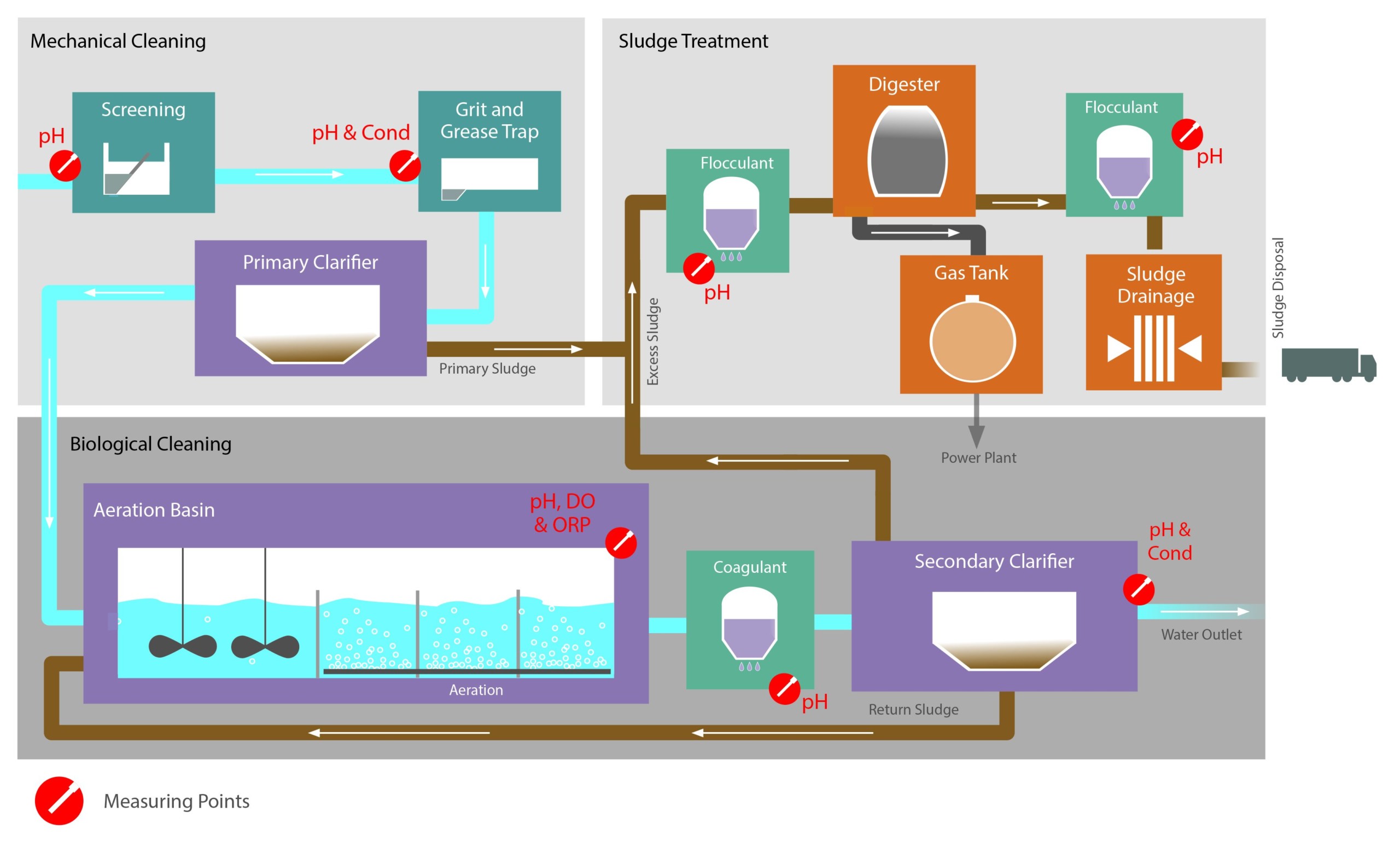

Selon le degré de pollution, les eaux usées contaminées par des composés organiques sont soumises à différentes procédures d’épuration, qui incluent entre autres la floculation et la précipitation : l’objectif de la floculation est l’agglomération des substances polluantes dissoutes pour obtenir des flocs filtrables, celui de la précipitation est la restructuration des substances polluantes pour former des composés lourds, qui se déposent au fond. Si, après de tels traitements, les eaux usées ne peuvent pas encore être considérées comme sans risques, des bactéries transforment, dans un bassin dit d’activation, les impuretés résiduelles en biomasse combustible ou réutilisable.

Les eaux usées ou l’eau de nettoyage issues de la production de denrées alimentaires et de boissons ou encore de process de fermentation présentent des pH très variables en fonction de l’application respective. Étant donné que les pH faibles peuvent aussi bien endommager des composants de l’installation que tuer des cultures bactériennes, la mesure du pH dans les conduites d’alimentation permet de prendre des contre-mesures à temps. Il est ainsi possible de neutraliser le pH en ajoutant des produits chimiques ou d’interrompre si nécessaire l’arrivée des eaux usées dans le bassin de décantation.

Grâce à sa conception prévue pour des pH extrêmes, la sonde Memosens SE554 est tout indiquée à la surveillance des eaux usées de l’industrie alimentaire. Sa fabrication en verre Alpha garantit une réponse rapide et stable. Le contact direct de l’électrolyte polymère par le biais d'un diaphragme perforé évite de façon fiable les problèmes liés à l’obstruction et au blocage dans des fluides fortement encrassés.

Mesure aisée du redox et de l’oxygène sous l’eau pour commander l’aération

Un paramètre important pour une aération efficace du bassin d’activation est le potentiel redox qui, en combinaison avec d’autres grandeurs de mesure, fournit des informations sur le rapport entre la teneur en oxygène et l’activité bactérienne. En tant que paramètre cumulatif, le potentiel redox n’indique pas de quantités absolues de substances, mais sa mesure continue permet d’observer les modifications de concentration au fil du temps. La comparaison des courbes de concentration avec d’autres valeurs sert de base à la commande de l’aération du bassin, afin d’atteindre une efficacité maximale des phases métaboliques aérobies ou anaérobies. L’expérience a cependant montré que les résultats de mesure les plus pertinents sont obtenus dans le premier quart du niveau du bassin.

Étant donné que l’électrode de mesure doit pour cela être immergée, la sonde Memosens SE565 a ici fait ses preuves pour la mesure du redox. En raison de la transmission inductive de la tension d’alimentation et des valeurs mesurées numérisées, toutes les sondes Memosens peuvent être utilisées sous l’eau sans problème. Cette sonde est également adaptée à l’utilisation dans des fluides agressifs, très encrassés ou bien contenant du sulfure ou des protéines. Afin de s’assurer que les microorganismes aérobies ont suffisamment d’oxygène, il faut aussi procéder à des mesures absolues des concentrations en oxygène dissous. Avec la SE715, vous disposez d’une sonde Memosens abordable pour la mesure simultanée de l’oxygène dissous et de la température, laquelle a spécialement été conçue pour la commande de l’activation et de l’aération dans les installations de traitement des eaux usées. Outre sa stabilité à long terme et son délai de réponse rapide, ses caractéristiques distinctives incluent aussi une faible dépendance aux courants.

Mesures sûres grâce à des supports sur mesure

Autre avantage, , les sondes peuvent être immergées dans le process grâce à des cannes d’immersion dans les bassins ouverts. La canne d’immersion ARD75 peut accueillir jusqu’à trois sondes de 12 mm en même temps (pH/redox, conductivité, oxygène). Le remplacement rapide des sondes par des modèles précalibrées en laboratoire ainsi que la fonction de rinçage intégrée pour nettoyer les sondes soulignent sa bonne adaptation aux stations d’épuration.

Retour sur investissement

- Grâce aux connexions Memosens inductives et insensibles à l’humidité, les sondes de mesure du pH, du potentiel redox et de l’oxygène dissous peuvent être immergées directement au niveau du poste de mesure souhaité, sans dispositif supplémentaire.

- L’absence de raccordements process habituels permet de réduire les coûts et simplifie considérablement le remplacement de la sonde.

- La grande qualité des mesures en dessous du niveau d’eau et la fiabilité à long terme des sondes Memosens améliorent la qualité du process.