Refinery Wastewater

Purification, neutralization and reuse - treatment of wastewater is as diverse as its impurities. Knick offers sensors, fittings and measuring devices, measuring technology for every measuring loop.

Keyfacts Processs/Application

Sector

[Proc]

Application

[Proc] What is produced: Raw material, reaction, product, waste materials, hazardous materials

[App] [location of measuring point] in [installation situation(pipe/tank/reactor) in [process step]. What are the measured values used for; how often is measured

Measured Parameter

pH, ORP, DO, Cond

Key Requirements

[App] Medium; Measuring range; Media properties:

- Temperature range

- Pressure range

- Ex/Non-Ex

- What were the special or biggest requirements: Operating environment, legal requirements, medium, pressure, temperature

pH Measurement in Contaminated Wastewater

In refineries, the individual process steps (e.g. distillation, cracker, desulfurization) also generate wastewater which has to be treated. The diagram shows a typical wastewater treatment process in a refinery. After separation of the aqueous components from the hydrocarbons, these are further processed under control of pH and oxygen content (bacterial degradation, filter stages). The resulting purified process water can be reused, and the dried sludge is disposed of.

Challenges

- Substances contained in the medium affect the performance of the pH sensors used (sludge, hydrocarbons, heavy metals...)

- Regular cleaning is absolutely necessary

- pH values are between 6-9

- Temperatures up to 30 °C

- Danger zone (Ex)

Why Knick ?

The sensor is automatically cleaned every few hours with 60 °C warm water, manual cleaning is therefore no longer necessary. The sensor only needs to be calibrated weekly. Before installation, the sensor had to be manual cleaned and calibrated every 2-3 days.

As a result, the lifetime of the sensor has doubled to more than 12 months.

H2 [Proc] [App] Application Description

[Proc]

[App] Detailed application description, why is measured, which customer problem is solved

H3 [App] Initial Situation

Was there a solution before, which was perhaps not good enough? Have requirements changed

H3 [App] Requirements of Application

What were the special or biggest requirements: Operating environment, legal requirements, medium, pressure, temperature, installation situation

H3 [App] Solution

Products used and why the solution was implemented in this form (transmitter, fitting, sensor, cCare)

Was a previous test necessary?

H2 [App] Video

HTML Text für Video

Headline Crosseling Products H2

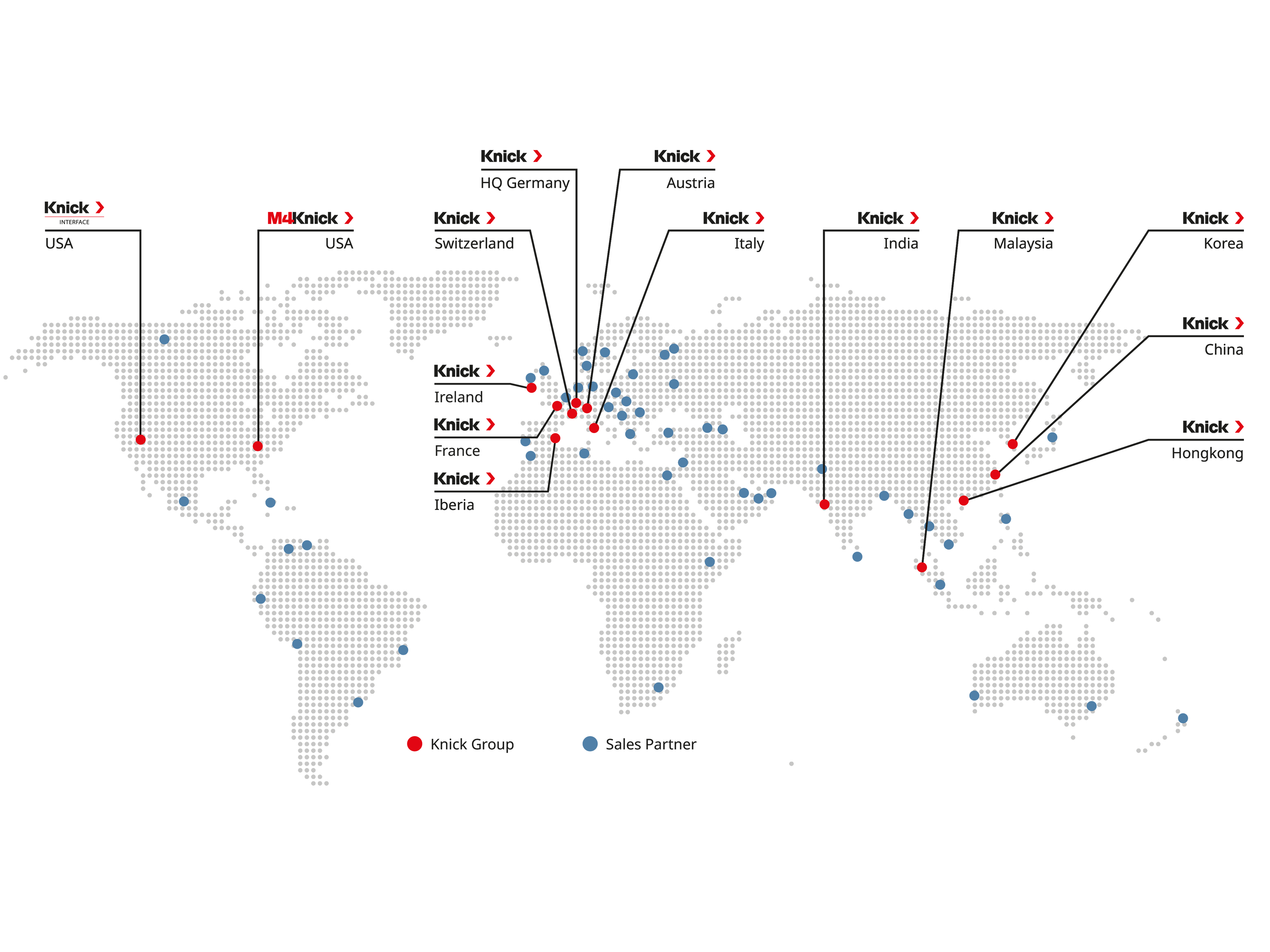

Related Industries and Applications

Overview of specific applications and product solutions in various fields of power plants.