Monitoring of Refinery Wastewater in Sour Water Strippers

Performance and availability of the entire plant often depend on pH measurements - accurate, reliable and durable solutions are required.

Keyfacts Processs/Application

Sector

[Proc]

Application

[Proc] What is produced: Raw material, reaction, product, waste materials, hazardous materials

[App] [location of measuring point] in [installation situation(pipe/tank/reactor) in [process step]. What are the measured values used for; how often is measured

Measured Parameter

pH, ORP, DO, Cond

Key Requirements

[App] Medium; Measuring range; Media properties:

- Temperature range

- Pressure range

- Ex/Non-Ex

- What were the special or biggest requirements: Operating environment, legal requirements, medium, pressure, temperature

pH Measurement in Sour Water

Sour water stripping is used to remove ammonia (NH3) and hydrogen sulfide (H2S) from sour water streams to condition it for discharge or reuse within the refinery. The streams, coming from distillation, fluid catalytic cracking, catalytic reforming, coker and acid gas removal units, are collected in a surge tank for centralized processing via a heat exchanger and a single stripper column, or two in series. A combination of pH control and heat, from direct injection steam or reboiler drives off the ammonia and hydrogen sulfide. The presence of solids and hydrocarbons (“oils”) are the major contaminants causing fouling of heat exchangers, stripper columns and reboilers. The impact, a loss of sour stripper capacity and the associated impairment of refinery performance, is to be avoided by appropriate measurements.

Challenges

- Installation in a hazardous area (Ex) in ventilated cabinet

- Possible exposure of plant technicians to toxic/corrosive gases during sensor maintenance

- Corrosive conditions

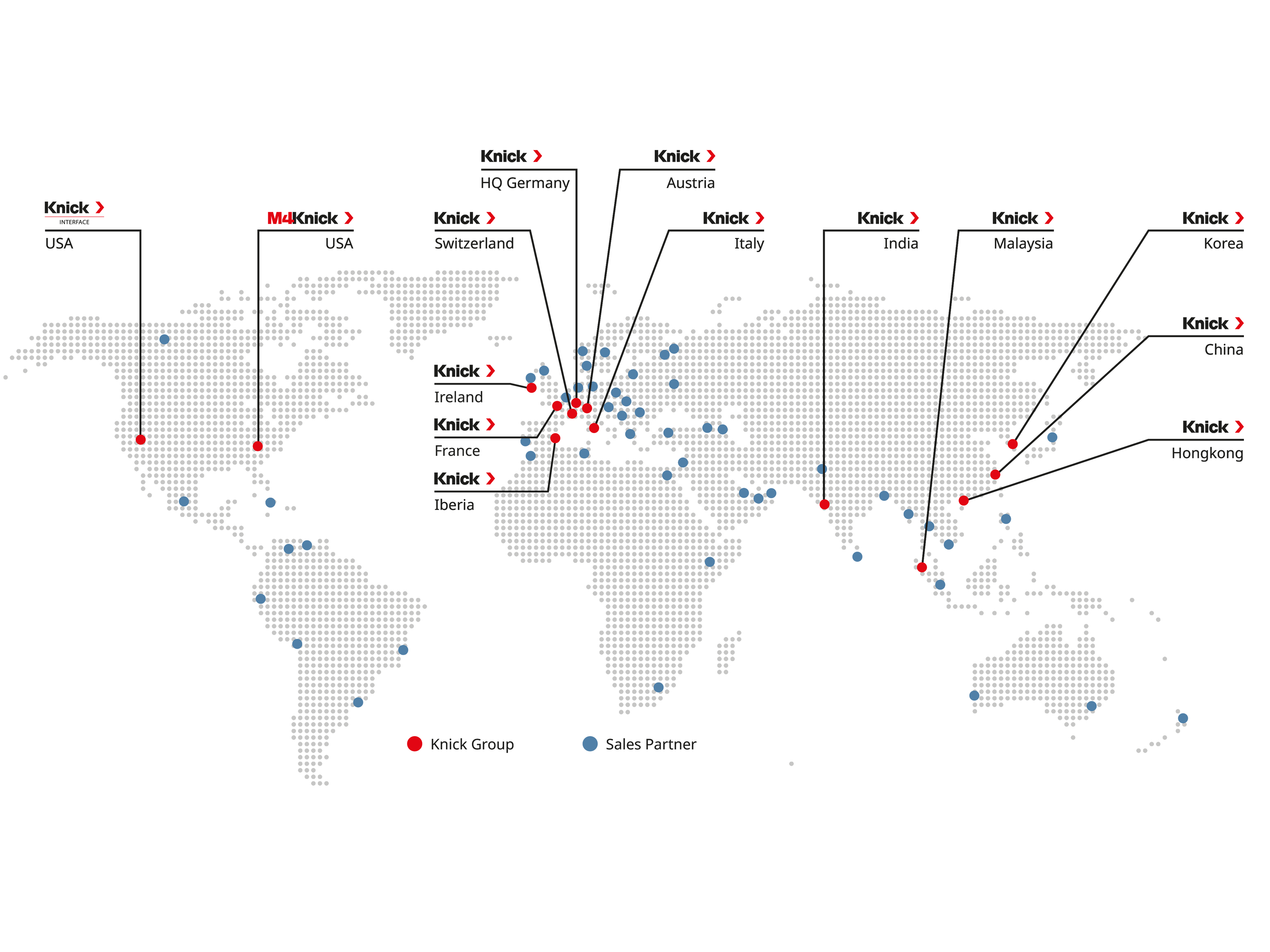

Why Knick ?

The safety functions and the sophisticated design of the SensoGate retractable fitting convinced the customer. The safe separation from the process avoids a health risk for employees during maintenance. The robust design ensures maximum reliability of the measuring loop.

H2 [Proc] [App] Application Description

[Proc]

[App] Detailed application description, why is measured, which customer problem is solved

H3 [App] Initial Situation

Was there a solution before, which was perhaps not good enough? Have requirements changed

H3 [App] Requirements of Application

What were the special or biggest requirements: Operating environment, legal requirements, medium, pressure, temperature, installation situation

H3 [App] Solution

Products used and why the solution was implemented in this form (transmitter, fitting, sensor, cCare)

Was a previous test necessary?

H2 [App] Video

HTML Text für Video

Headline Crosseling Products H2

Related Industries and Applications

Overview of specific applications and product solutions in various fields of power plants.