Temperature Measurement in Wind Turbine Generators

Keyfacts Process/Application H2

Sector

[App]

Application

What is produced/tested

What are the measured values used for; how often is measured

Measured Parameter

Galvanic Isolation

Voltage DC/AC

Current

Speed signal Conditioning

High-Voltage Temperature

Key Requirements

[App] Measuring range

Special requirements: Operating environment (i.e. high temperature, shock, vibration), legal requirements, working voltage...

Highly Insulating Temperature Transmitters Offer Protection Against Insulation Defects

Continuous temperature monitoring in wind turbine (WT) generators is essential for the precise control of the turbine, because the desired high efficiency requires reliable temperature management—in particular the ability to counteract thermal overload at an early stage. If an insulation fault occurs in the temperature detector at the generator, there is a risk of damage to the controller. As a result, the pitch control of the rotor blades could fail, potentially resulting in catastrophic turbine failure. WT operators therefore benefit considerably from highly insulated, robust measurement technology that reliably protects the controller, thereby preventing consequential damage.

Insulation Defects: An Expensive Risk

In gearless systems, where the nacelle of the wind turbine serves as a stator and the rotor is mounted directly on the rotor shaft, the temperature is monitored directly in the pole pieces of the rotor. Slot thermometers are inserted there for measurement. Since the effects of wear may occur even in carefully installed insulation, there is a risk that slot thermometers or supply lines may come in contact with the high potential of a phase and pose a hazard to downstream control systems.

High isolation of the transmitters that are used is therefore an essential prerequisite for preventing a thermal overload of the generator.

Why Knick ?

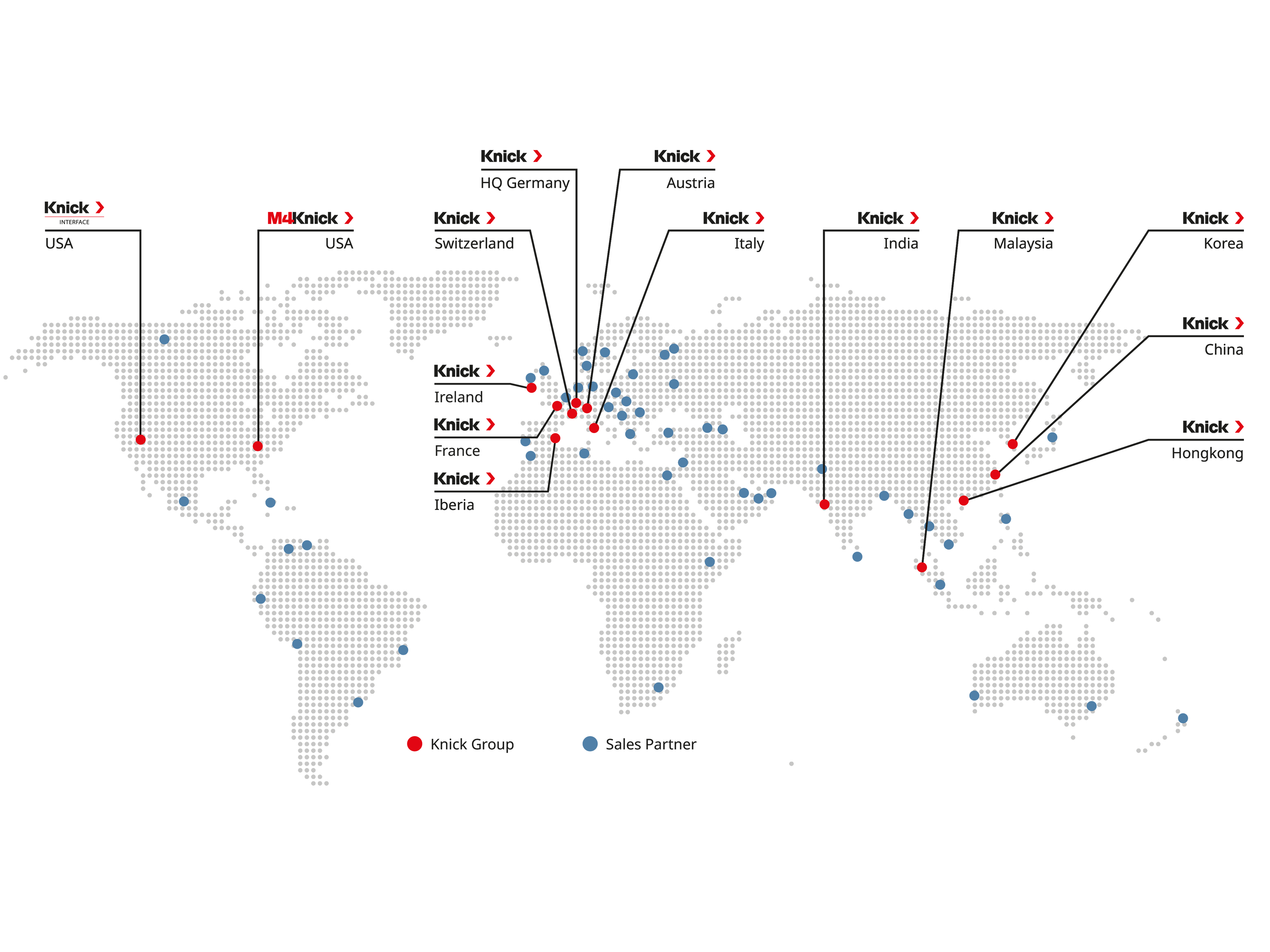

Where conventional temperature transmitters are unsuitable due to insufficient isolation, Pt100 transmitters from the P44000 series are used worldwide. Knick is able to develop customized solutions that easily withstand ambient temperatures ranging from -40 °C to +85 °C (as in the case of wind turbines), ensuring reliable operation despite these extreme conditions.

Excellent Insulation, Vibration Resistance, and Cold Resistance

The P44000 series temperature transmitters have already proven their robustness in countless applications worldwide. They are designed for permanent working voltages of up to 6.6 kV DC and convert the signals of Pt100 slot thermometers into standard signals with a very low measurement error of typically ±0.5 K. This enables precise control of the turbine that is stable over the long term.

Moreover, the vacuum encapsulation and the high vibration and shock resistance of the transmitters provide the necessary mechanical stability required for installation on the rotating part of the generator.