Inline tests of high-voltage heaters

High voltage heaters (HVH) are used to control the inside temperature of vehicles and to protect and manage various on-board systems, including batteries.

Since HVHs convert direct current into heat without losses, manufacturers often rely on this technology. Depending on the vehicle (small cars, buses, commercial vehicles, etc.), HVHs are developed for various operating voltages with a heat output of up to 10 kW.

Key facts about the application

Sector

Inline tests of high-voltage heaters in different production phases

Application

Checking the functions of the control electronics

Measured parameters

Voltages from 100 to 900 V DC and the corresponding current

Main requirements

Depending on the tested product, voltages of up to 900 V DC are applied

As part of assembly/inline tests, high voltages must be measured safely and accurately

For different applications, it is necessary to have a flexible choice among input voltages

Functional test of the control electronics

Description of application

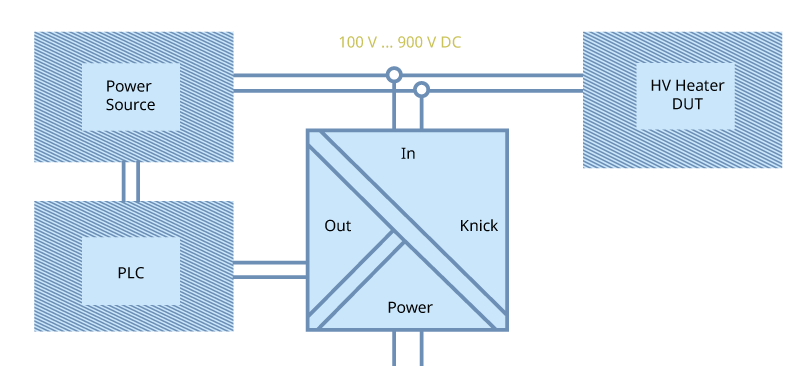

The production process for HVHs has many steps, some of which must be carried out manually. In the individual production phases, different inline tests are carried out. To do so, voltages of 100 to 900 V DC are applied to the HV heater components, depending on the heater type.

These voltages and the corresponding current are measured in order to check the function of the control electronics. In view of the risk of electric shock, the test object must not be touched during the test.

Requirements of the application

For reliable test results, precise and reliable measuring equipment must be used, since laboratory meters are not always used in a practice-oriented manner in production environments. In both end-of-line test benches and in test benches for the development phase, quality devices are found that have proven themselves in industrial applications. For this reason, high-quality devices proven in industry are not only used for end-of-line test benches, but are used in the research and development phase as well.

Why Knick?

The Knick P29000 high voltage transducer can measure voltages of up to 1000 V DC. Its accuracy is guaranteed by a gain error of < 0.2 % of the measured value and its safety by 3-port isolation with a working voltage of 1000 V AC/DC (basic isolation). Perfect isolation is documented by a high voltage test with 5.4 kV AC between input and output/auxiliary power. The input and output measuring ranges are configured via DIP switch behind the front cover of the device.

Matching products

Associated industries and applications

Overview of measuring technology applications and product solutions for electromobility