Denrées alimentaires et boissons

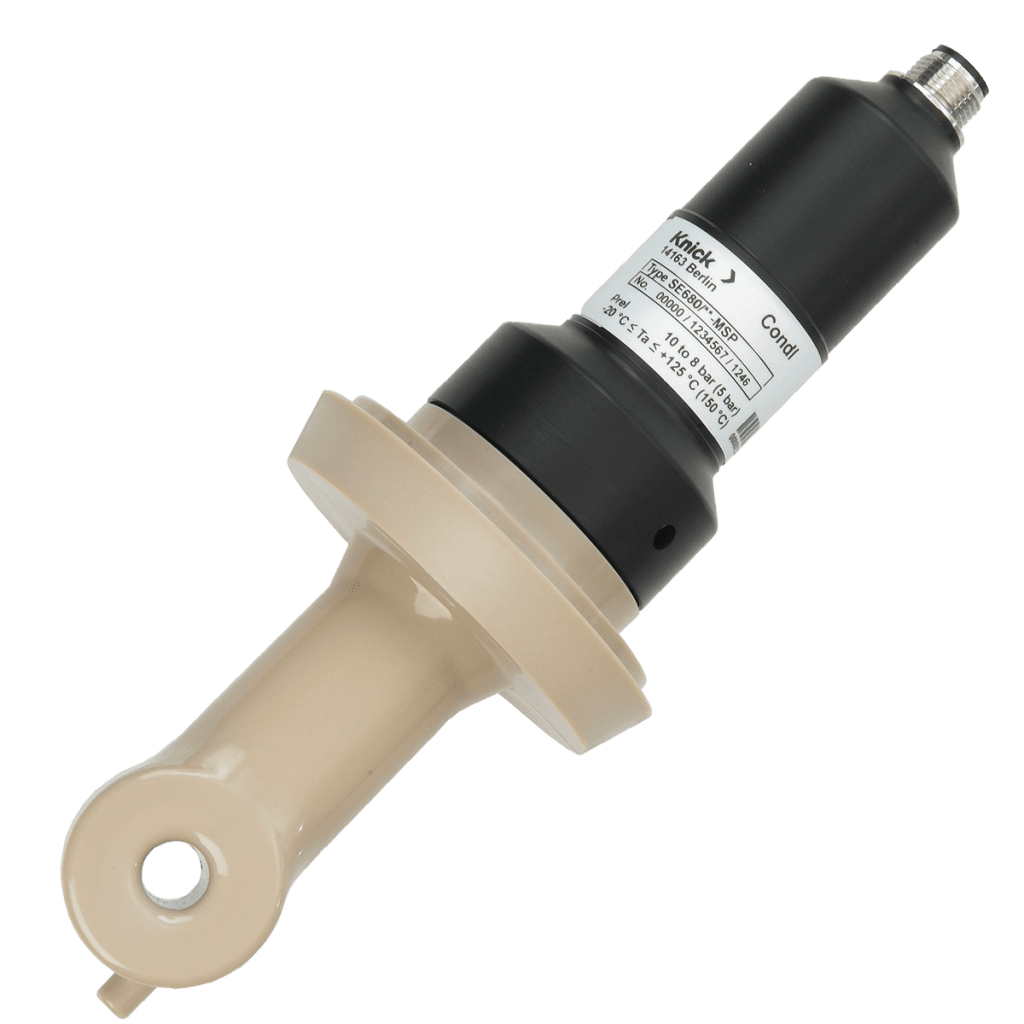

Knick conseille et soutient des entreprises de l’industrie alimentaires et des boissons dans l’analyse des liquides sans risque pour le process. Dans le cadre de l’optimisation de ces process, les paramètres critiques les plus fréquents sont le pH, l’oxygène et la conductivité.

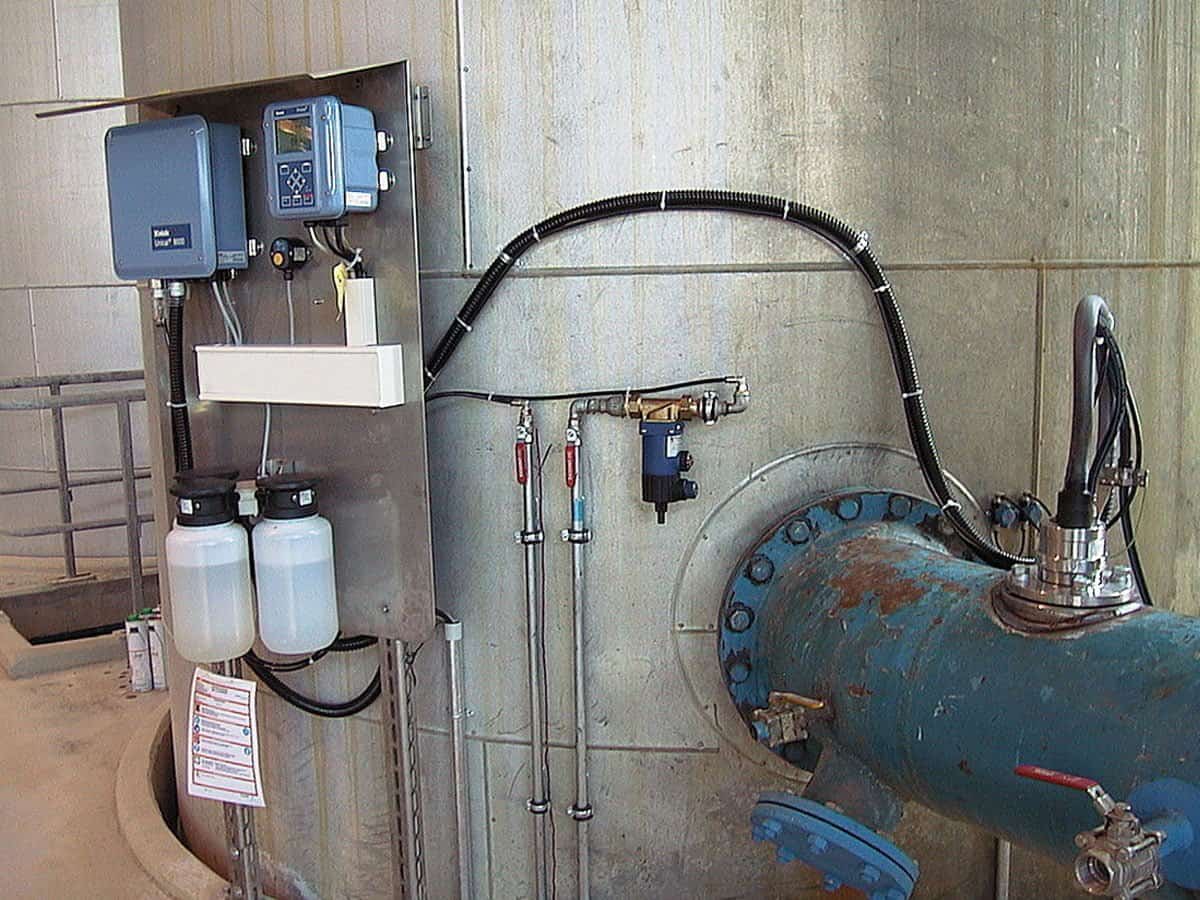

Avec son vaste portefeuille de produits incluant des sondes, des transmetteurs industriels, des supports ainsi que des systèmes de nettoyage et de calibrage, Knick propose des solutions et services sur mesure.

Sécurité des produits et qualité : un défi constant

L’assurance qualité au sein de l’industrie alimentaire inclut la surveillance et le contrôle de divers paramètres, afin de vérifier que les produits satisfont aux normes de qualité voulues et qu’ils sont propres à la consommation.

Les exigences posées à la technologie de mesure comprennent non seulement tous les aspects hygiéniques (compatibilité avec la SIP et le CIP), mais aussi la prévention des bris de verre et les mesures continues, étant donné que de nombreuses installations présentent un débit de production élevé. Parallèlement, les graisses, huiles et fluides visqueux compliquent la tâche des sondes, si bien que la tendance est aux postes de mesure entièrement automatiques avec nettoyage et calibrage des sondes pH.

Brasserie

Sucre

Laiterie

Chocolat

Pourquoi choisir Knick ?

Knick propose une offre complète allant des appareils de mesure mobiles pour les laboratoires ou les mesures d’échantillons sur le terrain jusqu’aux solutions de mesure entièrement automatiques assurant la maintenance des sondes. Ces produits naturellement hygiéniques présentent une séparation sûre vis-à-vis du process et ne contiennent pas de verre.

Applications correspondantes

Vous avez des questions ? Nous sommes à votre disposition.

Contactez-nous