ANALYSE DES PROCESSUS

Contrôle de la qualité lors de la livraison du lait cru

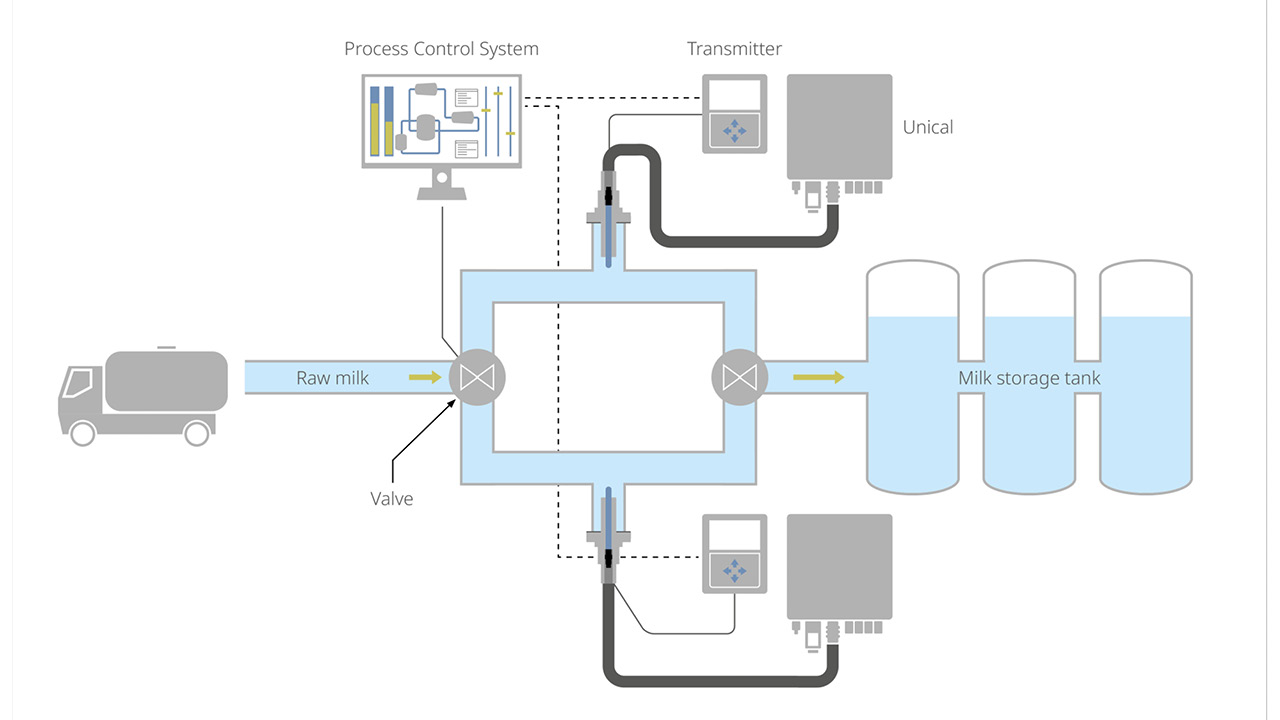

Les laiteries reçoivent des livraisons de lait cru 24 h sur 24. Ce lait cru est soumis à des exigences de qualité strictes, qui exigent une surveillance en ligne des opérations de déchargement des camions. Si du lait cru de qualité inférieure (lait acide) est versé dans les cuves de stockage, alors tout le stock de lait est contaminé.

Points essentiels de l’application

Secteur

Laiterie

Application

Surveillance en ligne de la procédure de déchargement

Paramètre de mesure

pH

Exigences principales

Mesure en ligne avec nettoyage et calibrage automatiques des sondes pour une disponibilité 24 h sur 24, 7 jours sur 7

Avertissements/alertes en cas de perturbation afin de pouvoir arrêter immédiatement le pompage du lait cru vers les cuves de stockage.

Respect de toutes les exigences d'hygiène telles que CIP et SIP

Mesure dans le lait cru

Description de l’application

La qualité du lait cru a un impact décisif sur la qualité des produits laitiers. Le lait frais a un pH compris entre 6,5 et 6,7. Les bactéries lactiques contenues dans le lait transforment le lactose en acide lactique, process qui dépend surtout de la température. Si le lait est acide, alors le pH diminue et, à partir d’un pH de 4,5, le lait commence à cailler. Voilà pourquoi la mesure du pH est idéale pour contrôler la qualité du lait dès sa livraison.

Exigence posée à l’application

Lors de la livraison du lait à la laiterie, une mesure du pH est absolument indispensable pour éviter la contamination de toute la cuve. Comme pour toutes les applications dans l’industrie alimentaire, les exigences sont ici particulièrement élevées : les sondes doivent non seulement être adaptées à une mesure précise du pH, mais aussi aux process habituels de CIP et SIP. Ces derniers sont utilisés pour le nettoyage et la stérilisation et sont réalisés en injectant des solutions de nettoyage et de rinçage ainsi que de la vapeur surchauffée dans le système fermé.

Pourquoi choisir Knick ?

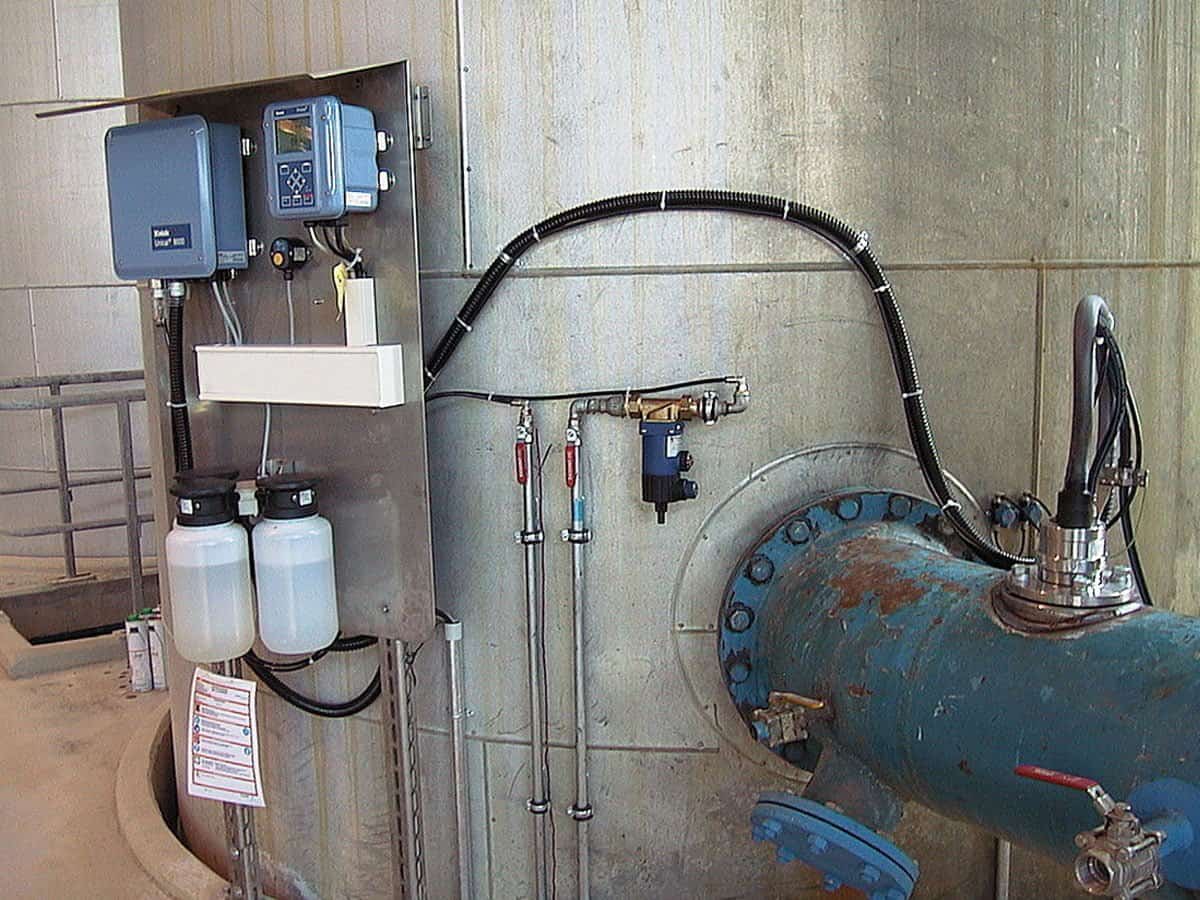

En combinant des sondes pH de qualité supérieure à un système d’analyse de process adapté, la qualité du lait cru peut être contrôlée dès son déchargement. La connexion à des systèmes immédiatement supérieurs permet de stopper le travail de déchargement sans délai si le pH est trop faible. La contamination d’une cuve complète est ainsi évitée efficacement. Grâce au système de nettoyage et de calibrage automatique ainsi qu’au support rétractable avec sas pour sonde, il n’est plus nécessaire de consacrer beaucoup de temps à démonter et à remplacer les sondes. Il en résulte ainsi une disponibilité élevée et une réduction du personnel de maintenance nécessaire.

Produits correspondants

Industries et applications correspondantes

Knick offers a solution to extend the life of pH sensors that are susceptible to wear, especially with difficult media: cCare ensures accurate measured values through fully automatic cleaning and calibration of pH sensors while reducing maintenance and material costs.