Isobutane and Propane Dehydrogenation

With pre-calibrated Memosens sensors, lower maintenance costs and savings in chemical consumption due to accurate measuring components.

Keyfacts Processs/Application

Sector

[Proc]

Application

[Proc] What is produced: Raw material, reaction, product, waste materials, hazardous materials

[App] [location of measuring point] in [installation situation(pipe/tank/reactor) in [process step]. What are the measured values used for; how often is measured

Measured Parameter

pH, ORP, DO, Cond

Key Requirements

[App] Medium; Measuring range; Media properties:

- Temperature range

- Pressure range

- Ex/Non-Ex

- What were the special or biggest requirements: Operating environment, legal requirements, medium, pressure, temperature

pH, ORP and Conductivity Measurements in Condensate

Isobutane and propane dehydrogenation is an important process for recovering butylene and propylene from liquid natural gas. They are used as feedstocks for e.g. plastics, lubricants, paints, rubber products or for additives. The process itself is closely monitored, using pH, redox and conductivity measurements. Monitoring of the condensate is particularly important here, as this allows direct conclusions to be drawn about the process itself. Mineral deposits interfere with heat transfer in the system, pH monitoring controls the addition of the phosphonate-based inhibitor and ORP measurement monitors the chlorine content in the condensate to prevent bacterial growth.

Challenges

- Installation in hazardous area (Ex)

- Installation in pipes with small diameter

- Regular maintenance of the measuring loops necessary

Why Knick ?

By using Memosens sensors, which are pre-calibrated, the time spent in the process unit and thus the maintenance costs have been significantly reduced. The high quality of the fittings, sensors, and transmitters proved the components robust to the H2S environment. The accuracy, availability and reliability of the measurements helped reduce chemical consumption due to better process controllers/p>

H2 [Proc] [App] Application Description

[Proc]

[App] Detailed application description, why is measured, which customer problem is solved

H3 [App] Initial Situation

Was there a solution before, which was perhaps not good enough? Have requirements changed

H3 [App] Requirements of Application

What were the special or biggest requirements: Operating environment, legal requirements, medium, pressure, temperature, installation situation

H3 [App] Solution

Products used and why the solution was implemented in this form (transmitter, fitting, sensor, cCare)

Was a previous test necessary?

H2 [App] Video

HTML Text für Video

Headline Crosseling Products H2

Related Industries and Applications

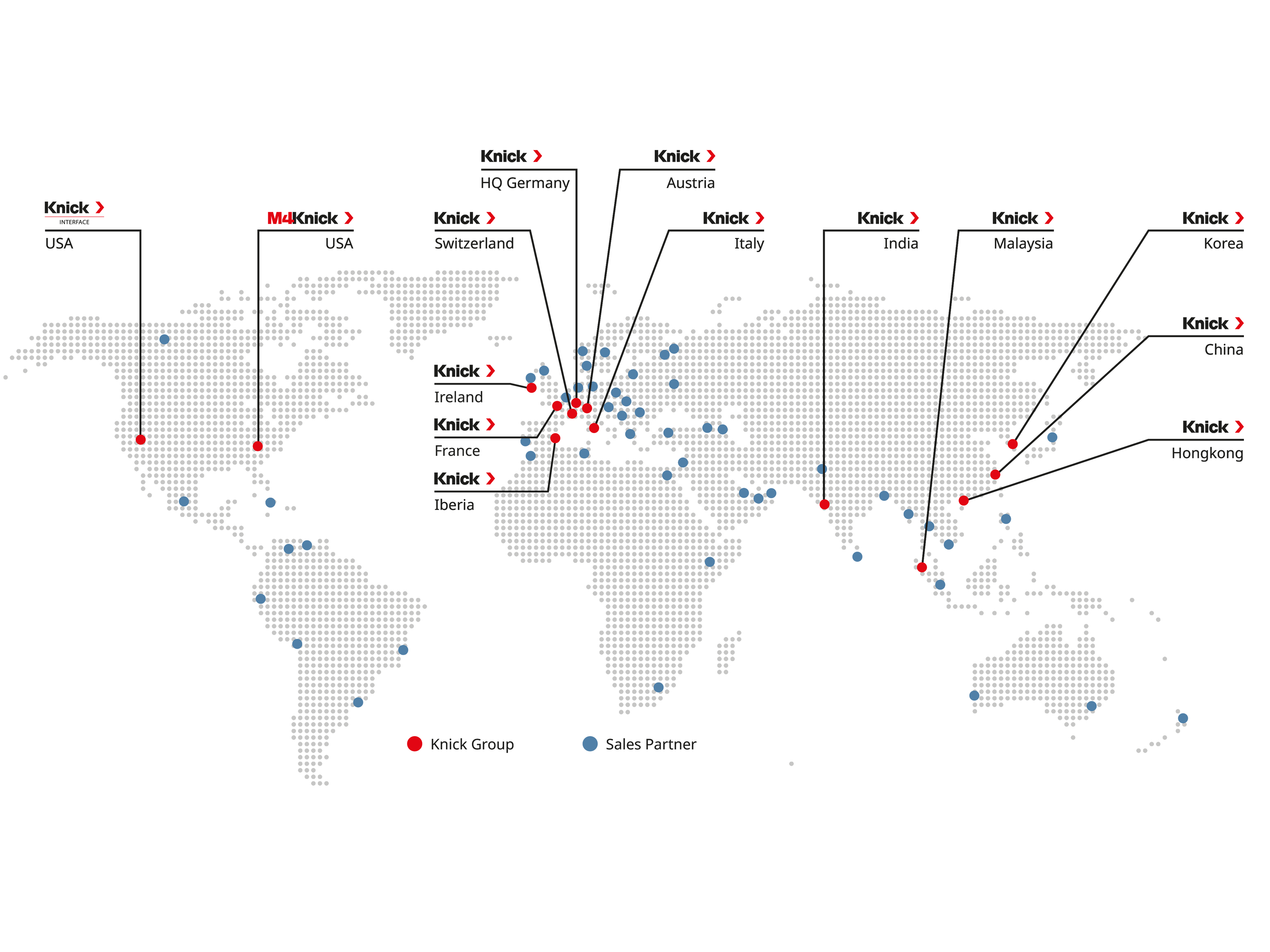

Overview of specific applications and product solutions in various fields of power plants.